8

•

800-356-1688

Tobeginsampling,using the formal samplingcanister, follow thesesteps:

1. Remove the brass capnut from the canister valve.

2. If you areusing a test gauge, attach the gauge to the canister and record the vacuum reading. If you choosenot touse a test

gaugeunder field conditions, record the readingon the vacuum gauge that is part of the passive sampling train.

3. Attach the verifiedpassive sampling train to the canister.

4. Record the sampling start time andnecessarymeteorological data.

5. Open the canister valve andbegin sampling.

6. Periodically check the canister throughout the samplingperiod to ensure thepressure reading is accurate and sampling is pro-

ceeding as planned.

7. Once the samplingperiod is complete, close the valve and remove the sampling train.Check the final pressurewithin the canis-

ter, using the test gauge or the vacuum gauge in the sampling train.

Thereare fourpossiblescenarios:

A. Ideally therewill beavacuumof -7"to -4"Hg in thecanister (e.g.,Table IV).

B. Ifmore than -7"Hgvacuum remains, less samplewas collected than ini-

tially anticipated.The samplewill be valid, but thedetection limitmaybe

higher than expected.Youmight have topressurize the canister prior to

the analysis,whichwill dilute the sample and require you touse adilution

factor todetermine final concentrations of target compounds.

C. Avacuumof less than -4"Hg indicates the samplemight be skewed

toward the initial part of the samplingperiod.This assumptionusually is

validbecause the flow rate through the flow controllerwill fall once the

vacuum falls below -5"Hg (Figure6, page4),when the change inpressure

across the flow controller diaphragmbecomes too small and the flow con-

troller is unable tomaintain a constant flow.Although flowwasnot con-

stant over the entire samplingperiod, the samplemaybeusablebecause

samplewas collectedover the entire interval.

D. If the endingvacuum is less than -1"Hg the sample shouldbe considered

invalidbecause itwill be impossible to tellwhen the sample flow stopped.

8. Record the final pressure in the canister and replace the capnut.

Information that should be acquired at the sam-

pling site includes the start time and interval time,

the stop time, atmospheric pressure and tempera-

ture and, for ambient sampling, wind direction.

Include elevation if it is a factor. These parameters

oftenprove veryuseful when interpreting results.

After sampling, the canisters are sent back to the

laboratory where the final vacuum is measured

again with a test gauge. Using the initial vacuum

and final vacuum, the samplevolume collected can

be determined fromEquation1.

It is alsogoodpractice to recheck the flow rate after

sampling,because thiswill affect the samplevolume

(Equation 2). Laboratories typically allow a maxi-

mumdeviationof ±10% to±25%between the ini-

tial flow rate and thepost-sampling flow rate.

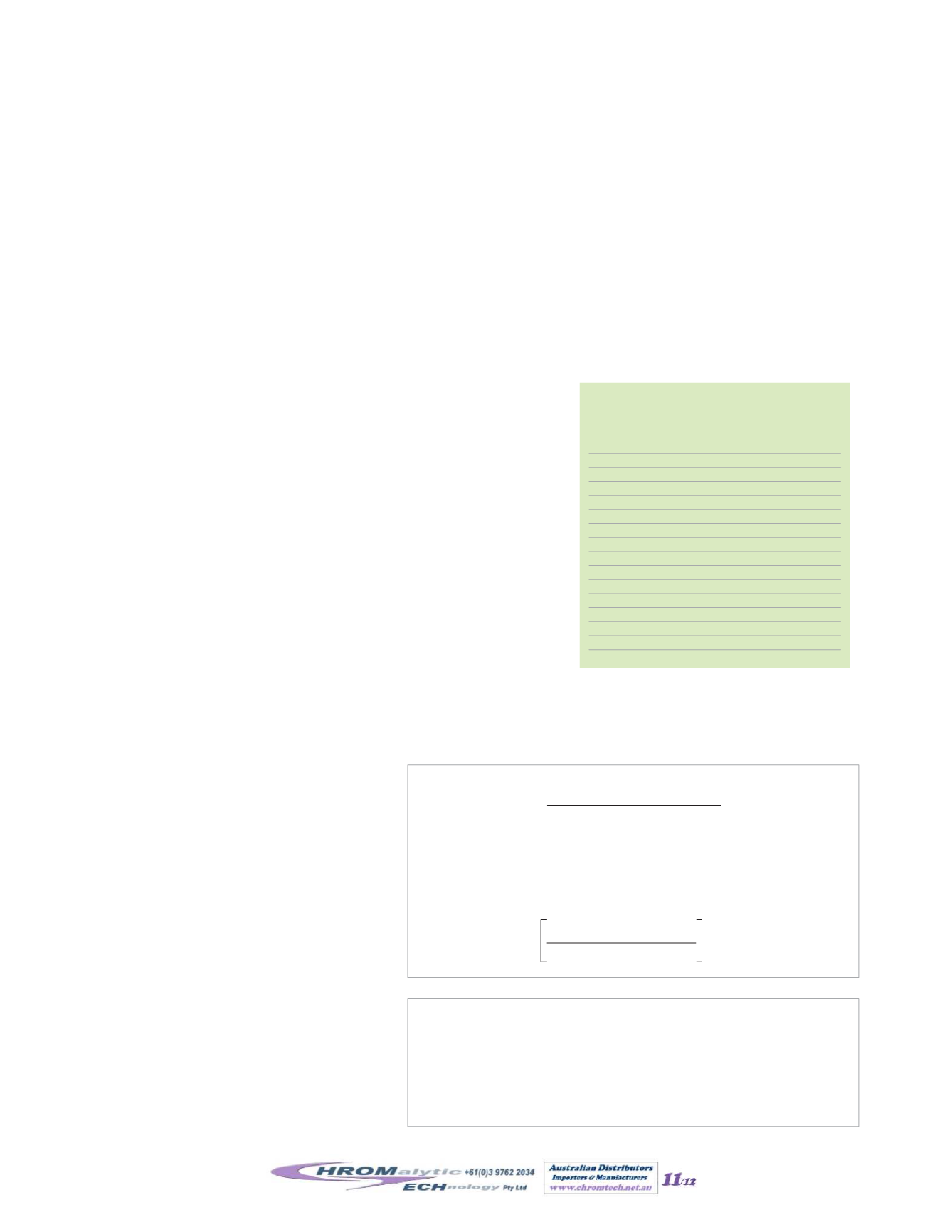

Table IV

Final vacuumandvolumeof

sample collected in6-liter canister.

Final Vacuum

Sample Volume

("Hg)

(liters)

29

0

27

0.58

25

0.99

23

1.39

20

1.99

17

2.59

15

2.99

12

3.59

10

3.99

7

4.60

5

5.0

3

5.40

0

6

Equation2:

samplevolume=[(initial flowrate+post-sampling flowrate)/2]xsampling time

Example: A flow controller was set at 3.3 mL/min. After obtaining a 24-hour

sample the flow ratewas 3.0mL/min.

sample volume=[(3.3mL/min.+ 3.0mL/min.)/2] x 1,440min.= 4,536mL

Equation1:

pressure change*

sample volume=

x canister volume

initial pressure

*initial pressure– final pressure

Example: A sample is collected in a 6-liter canister. The initial gauge pressure

reading when the canister left the lab was -29.92" Hg vacuum; the final gauge

pressure readingwhen the canisterwas returned to the labwas -7" Hg vacuum.

-29.92" Hg– (-7" Hg)

sample volume=

x 6L=4.59 literscollected

-29.92" Hg

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA