4

•

800-356-1688

upstreamof aconstantbackpressure.This constantbackpressure is established

by the balance between themechanical spring rate of the diaphragm and the

pressuredifferential across thediaphragm.The latter is establishedby thepres-

sure difference between the atmospheric pressure, the vacuum in the canister,

and the flow through the critical orifice.Thenet result is a constant flow.

The critical orificedetermines the flow range.The adjustablepiston is used to

set a specific, fixed flow ratewithin the flow range.An adjustment to theposi-

tion of the piston changes the back pressure, which changes the pressure dif-

ferential across the critical orifice. If the piston is lowered away from the

diaphragm, the flow rate will increase. If the piston is raised toward the

diaphragm, the flow rate will decrease. This flow controller will accurately

maintain a constant flow despite changes in vacuum over a range of -30"Hg

to -7"Hg. Flow is constant until the vacuum range of the device is exceeded,

making the flow controller unable tomaintain the constant pressure differen-

tial. In Figure 6, for example, the flow rate is constant from -29.9" Hg to

approximately -7"Hg, atwhichpoint the flow rate decreases because the flow

controller is unable tomaintain the proper pressure differential. This control

will allow theuser to collect approximately5 liters of sample in a6-liter canis-

ter. This is an extremely important factor in obtaining valid time-integrated

samples through passive sampling.We will discuss this point further in the

FieldSampling

(SectionV) of this guide.

FieldSamplingandLaboratoryVacuumGauges

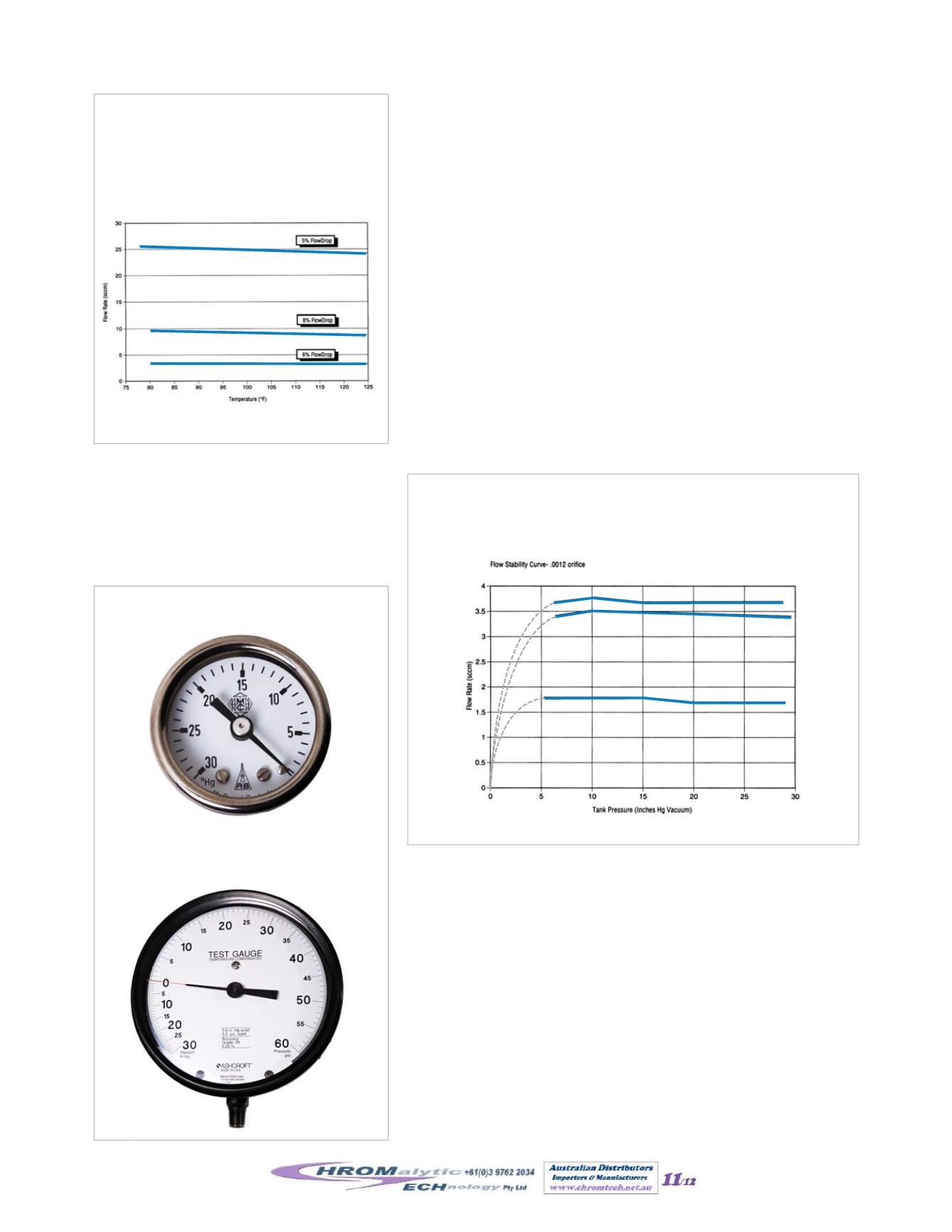

A vacuum gauge as shown inFigure 7A enables samplingpersonnel to visually

monitor changes in thevacuum in thecanisterduring sampling. If the flow rate

changes unexpectedly (e.g., due to a leak or an incorrect setting), the vacuum

gaugewill indicateadisproportionatelyhighor lowvacuum in thecanister,and

correctiveactioncanbe taken (i.e., flowadjusted) in time toensureavalid sam-

ple. This type of vacuum gauge is attached to the sampling train for use in the

field. The vacuum gauge should be of high quality to ensure that it does not

introduce contaminants into the sample.All wettedparts in the vacuum gauge

areconstructedof stainless steel;Restekgauges areaccurate towithin1%of full

scale.Onceused for sampling, agaugemust be cleaned, and shouldbe certified

clean.Procedures aredescribed later in this guide.

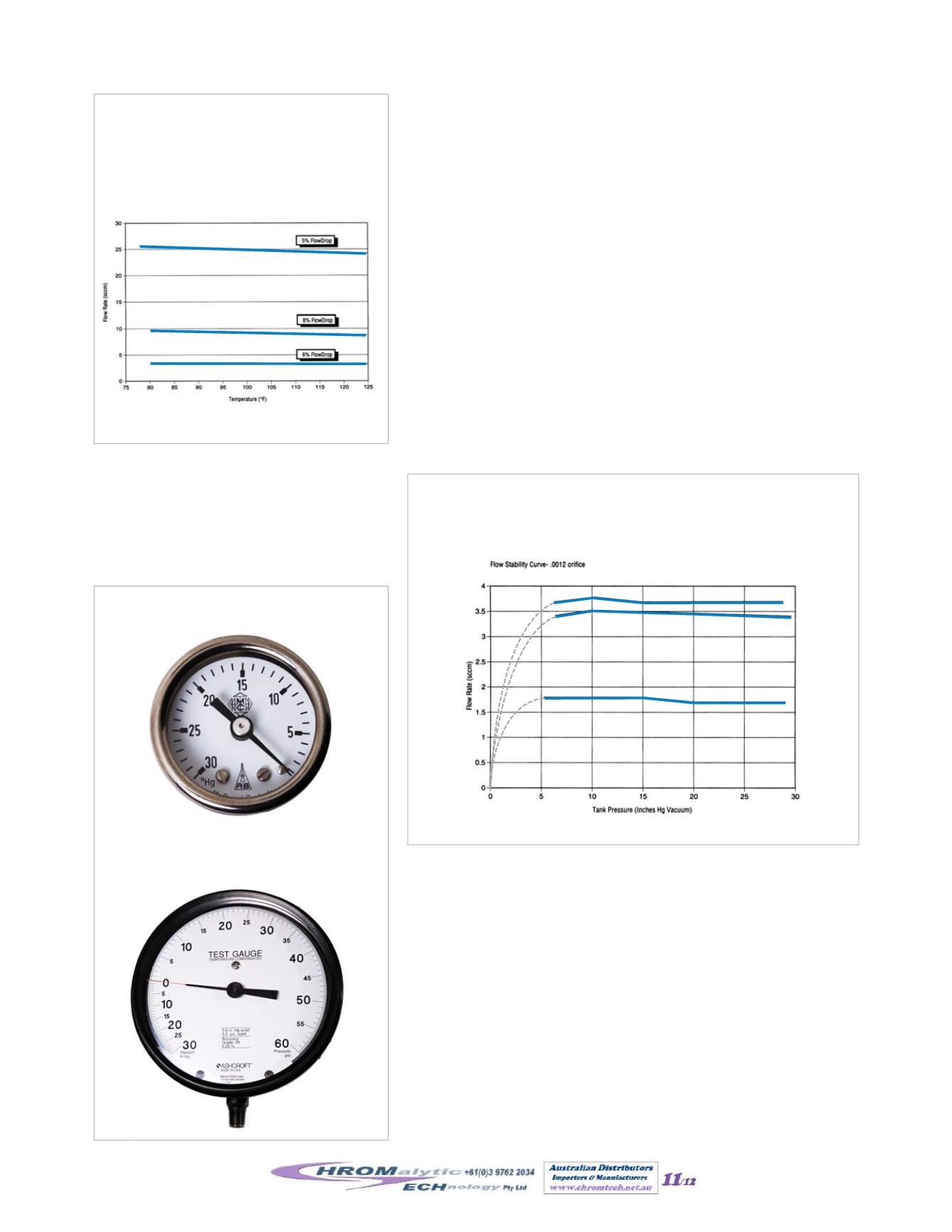

Tomonitorpressure in the canisterbeforeandafter sampling,useamoreaccu-

ratemeasuringdevice. For example, test gauges built byAshcroft®, as shown in

Figure7B, are accurate to0.25%of full scale.These sensitive gauges shouldnot

beused in the field—they typically arewallmounted in the lab.

Courtesy of Veriflo Corp., a division of Parker Hannifin Corp.

Figure6

A flow controllerwillmaintaina constant sample flow

until it isunable tomaintaina stablepressuredifferential across

the critical orifice.

DifferentialPressureResponse

Figure7A

FieldSamplingGauge

Figure7B

HighAccuracyLaboratoryGauge

Figure5

A flow controllerwillmaintaina

constant sample flowdespite changes in

canister pressureor environmental

temperature.

TemperatureEffects

Courtesy of Veriflo Corp., a division of Parker Hannifin Corp.

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA