3

800-356-1688

•

Sampling Inlet

The sampling inlet—the entrance to the sampling train—typically is cleaned

stainless steel tubing, either

1

/

4

"ODor

1

/

8

"OD.USEPACompendiumMethod

TO-14A/15 recommends samplingat aheight of 2meters above theground. In

ahighly traffickedarea,thiswouldminimize theproblemofdustparticlesenter-

ing thesampling train.Thisheight isnotmandatory,however,and it iscommon

practice touse an inlet that is 12" (approximately

1

/

3

meter) high.TheEPA also

recommends having the entrance of the sampling inlet face downward topre-

vent raindrops from entering the inlet. In some sampling trains, a

1

/

8

"or

1

/

4

"nut

at theentranceof the inlet keepswaterdroplets away from theedgeof the inlet,

where they couldbedrawn into the sampling trainwith the sample.

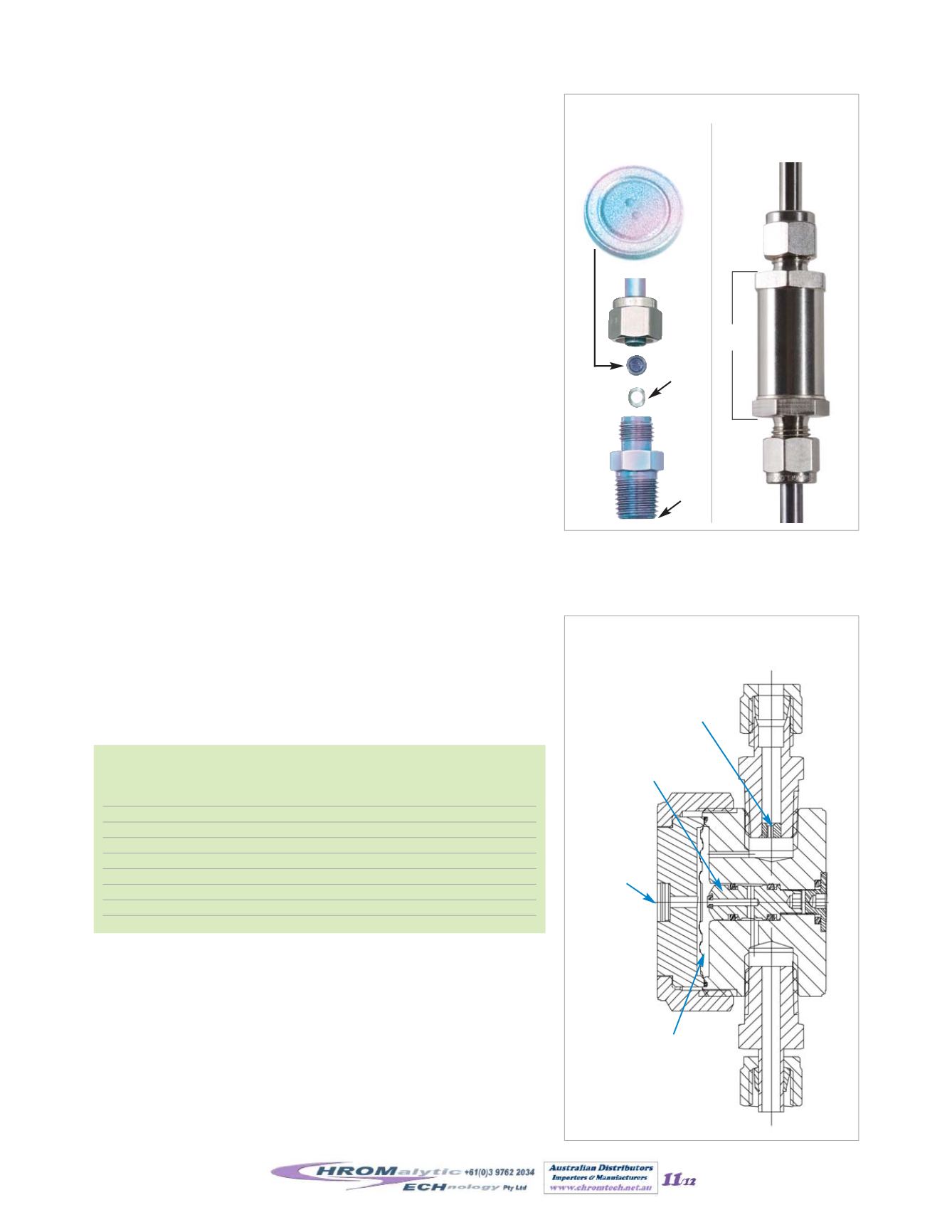

ParticleFilter

Theparticle filter is installed in the sampling trainprior to the flow-controlling

device to prevent airborne particles from entering the sample flow path.

Particles could partially obstruct the flow path and alter the flow rate during

sampling. Inextremecases,particles couldplug the flowpathand stop the sam-

ple flow. The smallest orifice commonly used in a passive sampling train is

0.0012" (approximately30micrometers).Without aparticle filter,dustparticles

couldocclude thisopeningas theyaccumulate in theorifice fitting.Particlesalso

canaffect the leak integrityof thevalve, andpossiblycausedamage to thevalve.

Two types of filters are used for this application, frit filters and in-line filters

(Figure 3).A varietyofmodels of each type are available;most are of sintered

stainless steel and have 2-, 5-, or 7-micron pores. Use of smaller pore filters

reduces the likelihoodof problems fromairborneparticles.EPACompendium

MethodTO-14A/15 recommends using aparticle filterwith2-micronpores.

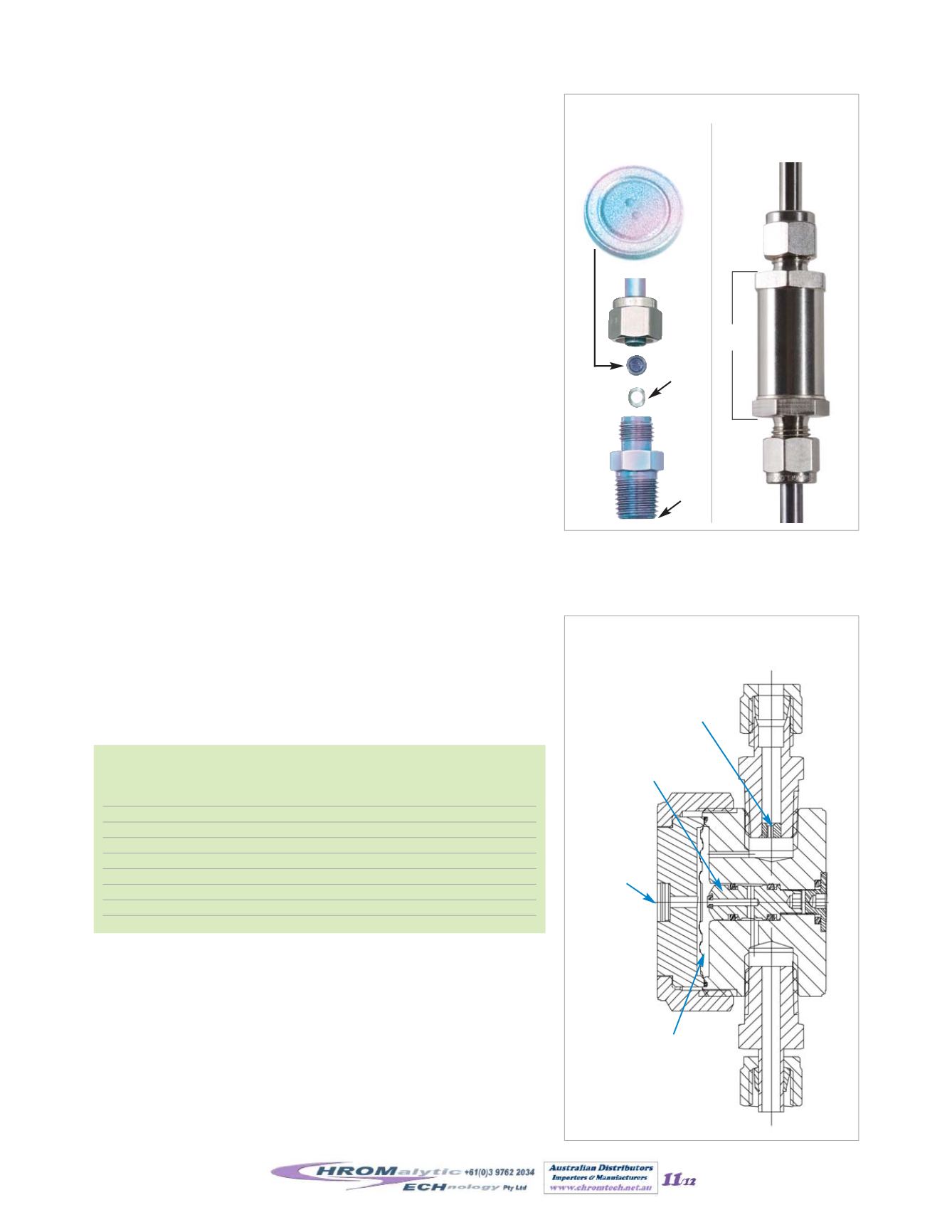

CriticalOrifice

The critical orifice (Figure 4) restricts the flow to a specified range (Table II). In

conjunctionwith the flowcontroller, thisallows thecanister to fill atacertain rate

overaspecified timeperiod.Themostcommoncriticalorificedesign isaseriesof

interchangeablestainlesssteel

1

/

4

"NPT to

1

/

4

"compressionunions,each fittedwith

apreciselyboredrubyorifice.Eachorificeprovidesaspecific flowrange(TableII).

Stabilityoverawide rangeof temperaturesmakes ruby theconstructionmaterial

of choice.Typicallyduring field sampling, the sampling train is subjected to tem-

perature fluctuations thatwouldcausemetals tocontractorexpand,affecting the

diameterof theapertureand therebyaffecting flow.Rubywillnot expandorcon-

tract across ambient temperatureextremes incurredduring sampling.

A critical orifice can be used as the sole flow-restricting device, but it cannot

ensure uniform flow. Since the source pressure of the flow changes during

sampling, the flow rate through the orifice can also change, resulting in an

invalid time-integrated sample. It is important that a highly consistent flow

rate bemaintained during passive sampling, and this is accomplished by the

flow controller.

FlowController

The flow controller (Figure 4)maintains a constant sample flowover the inte-

grated timeperiod,despitechanges in thevacuum in thecanister,or in theenvi-

ronmental temperature (Figure 5). In the Veriflo® Model SC423 XL Flow

Controller shown in Figure 4, the critical orifice acts as a flow restrictor,

Table II

Critical orificediameter vs. flow rate.

OrificeDiameter

FlowRateRange

Canister Volume / Sampling Time

(in.)

(mL/min.)

1L

3L

6L

15L

0.0008

0.5–2

24 hr.

48 hr.

125 hr.

—

0.0012

2–4

4 hr.

12 hr.

24 hr.

60 hr.

0.0016

4–8

2 hr.

6 hr.

12 hr.

30 hr.

0.0020

8–15

1 hr.

4 hr.

8 hr.

20 hr.

0.0030

15–30

— 2 hr.

3 hr.

8 hr.

0.0060

30–80

— — 1.5 hr.

4 hr.

0.0090

80–340

— — 0.5 hr.

1 hr.

Figure3

Filtersused in sampling trains.

critical

orifice

frit filter

stand

alone in-line filter

Frit filter inside

passive samplingkit

Figure4

Flow controller & critical orifice.

atmospheric

reference

inlet

outlet

critical

orifice

adjustable

piston

diaphragm

Drawing courtesy of Veriflo Corp.,

a division of Parker Hannifin Corp.

spring

washer

in-line

filter

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA