Our 20-page technical guide describes the

components of a passive sampling train, and

presents procedures for sampling, for cleaning,

and for certifying the sampling train and canister.

Request lit. cat.# 59977A.

• 13 •

www.restekcorp.com2003

Volume 3

800-356-1688

SilcoCan

™

Canisters

Ideal for Low-Level (1ppb-20ppb)

Reactive Sulfur Compounds

Reference

1

Stability study of Low-Level (1ppb-20ppb) Reactive Sulfurs in SilcoCan

™

Canisters.

Restek Corporation, 2001.

Available on request: lit. cat.# 59347.

SilcoCan

™

Air Sampling Canisters

SilcoCan

™

Canisters with

Vacuum/Pressure Gauge

volume

qty.

cat.#

1L

ea.

24112

3L

ea.

24113

6L

ea.

24114

15L

ea.

24115

Feature

High-purity,

2

⁄

3

-turn valve with stainless steel valve diaphragms.

Vacuum/pressure gauge (optional).

Variety of sizes.

Temperature stability to 250°C.

Silcosteel

®

valve available (add suffix “-650” to cat. #).

No sample adsorption, for more accurate results; easy to use.

Silcosteel

®

coated.

Inert surface, ideal for containing low-level sulfur compounds.

Indicates internal conditions.

Meet extensive range of sampling needs.

Can be cleaned at higher temperature, producing a cleaner can.

Completely passive sample pathway ensures sample stability.

Analysis of low-level sulfur volatile organic com-

pounds (VOCs), such as hydrogen sulfide (H

2

S),

methyl mercaptan (CH

3

SH), ethyl mercaptan

(C

2

H

5

SH), and dimethyl disulfide (CH

3

SSCH

3

) is

important because of health concerns and odor

complaints near manufacturing sites and refineries.

Collection and measurement of these compounds in

the atmosphere is very difficult because of their low

concentrations and high reactivity. Sulfur VOCs can

react not only with each other, but also with the

Benefit

vessels in which they are collected. This causes low

recoveries. SilcoCan

™

air monitoring canisters,

which feature a Silcosteel

®

-treated surface, ensure

stability of low-level sulfur VOCs.

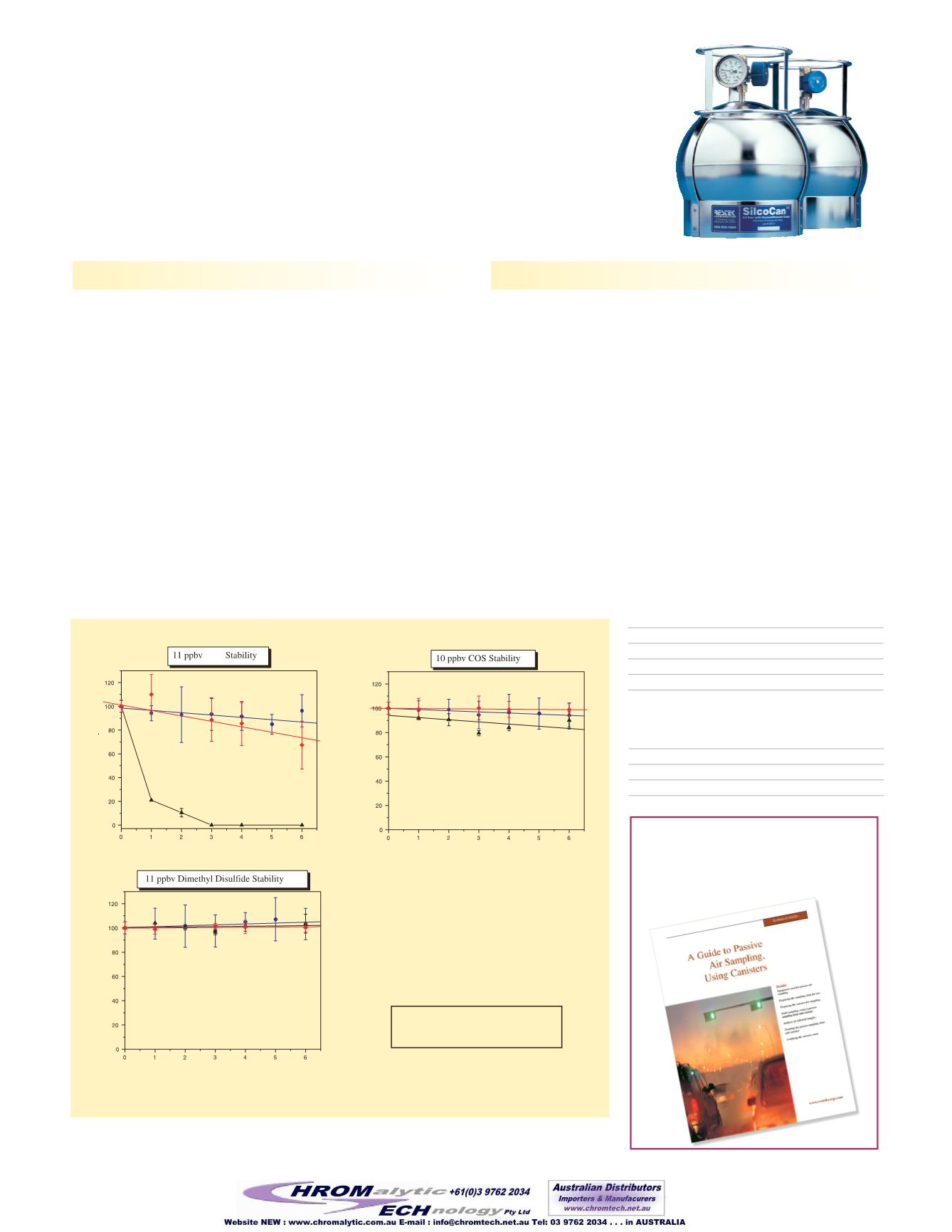

We evaluated the stability of sulfur VOCs in

SilcoCan

™

canisters at very low levels (1–20ppbv)

for six days.

1

Comparison of dry vs. humidified

standards demonstrates the ability of SilcoCan

™

canisters to store low-level sulfur VOCs in real-world

conditions (Figure 1). Electropolished canisters

allowed rapid degradation of hydrogen sulfide,

methyl mercaptan, and ethyl mercaptan during a

similar study.

When you need to perform sensitive air monitoring

analyses for sulfur VOCs, use SilcoCan

™

canisters to

collect and store your samples.

Rtx

®

-1, 60m, 0.53mm ID, 7.0µm (cat.# 10193)

GC:

Agilent 5890GC

Det.:

Sievers Model 355 SCD

Oven Temp.:

30°C (hold 1.0 min.) to

180°C @ 10°C/min. (hold 5 min.)

Flow Rate:

8.5mL/min.

Sample:

1mL (sample loop)

Standards: 2mL of 100ppm stock sulfur standard added to each precleaned and evacuated canister, then pressurized to 30psig with ultra-pure nitrogen.

The resultant concentrations are listed in Applications Note #59347. Humidified standards made by injecting evacuated canisters with 100µL of deionized

water prior to adding 2mL aliquot of stock standard (50% RH).

Dry SilcoCan

™

(n=18)

Humidified SilcoCan

™

(n=5)

Electropolished canister (n=2)

●

◆

▲

Figure 1

- SilcoCan

™

canisters effectively store low-level organic sulfur compounds under real-world conditions.

Time (Days)

Time (Days)

Percent Recovery

Percent Recovery

2

H S

1L

ea.

24116

3L

ea.

24117

6L

ea.

24118

15L

ea.

24119

By Donna Lidgett, Air Sampling Products Marketing Manager

✔

Stable, long-term storage of sulfur volatile organic compounds.

✔

More accurate data than with electropolished canisters.

Percent Recovery

Time (Days)