www.restek.com

www.restek.com

121

GC COLUMNS |

PLOT COLUMNS

Fused Silica Alumina BOND Columns

Rt®-Alumina BOND Columns

Restek® Rt®-Alumina BOND columns are highly selective for C1–C5 hydrocarbons

and separate all saturated and unsaturated hydrocarbon isomers above ambient tem-

peratures. The reactivity of the aluminum oxide stationary phase is minimized to

improve column response for polar unsaturates, such as dienes, and the column’s

sensitivity (or response) ensures linear and quantitative chromatographic analysis for

these compounds. Strong bonding prevents particle generation and release, which al-

lows valve switching without harming the injection or detection systems. And because

they are stable up to at least 200 °C, Rt®-Alumina BOND columns can be regenerated

to restore full efficiency and selectivity by conditioning at their maximum temperature

if water is adsorbed. High capacity and loadability give you exceptionally symmetrical

peaks, making these columns ideal for volatile hydrocarbon separations at percent lev-

els, as well as impurity analyses at ppm concentrations. Restek® Rt®-Alumina BOND

PLOT columns are manufactured on fused silica tubing; select phases are also available

on metal MXT® tubing.

To ensure reproducible retention times and predictable flow behavior column-to-col-

umn, each Rt®-Alumina BOND column is extensively tested. A hydrocarbon test mix

confirms proper phase retention and selectivity. To calculate k (retention or capacity

factor), which is a measure of phase retention, 1,3-butadiene is used, while selectivity is

measured using retention indices for propadiene and methyl acetylene. The resolution

of

trans

-2-butene and 1-butene is also verified and, to measure efficiency, plates per

meter are checked using 1,3-butadiene.

Rt®-Alumina BOND/Na

2

SO

4

Columns

(fused silica PLOT)

(Na

2

SO

4

deactivation)

• Acetylene and propadiene elute after butanes.

• Best separation for butene isomers (impurities in butene streams).

• Methyl acetylene elutes after 1,3-butadiene.

• Cyclopropane (impurity in propylene) elutes well before propylene.

• Stable to 200 °C.

tech tip

TraceWater in the Carrier Gas

Traces of water in the carrier gas and samples

will affect the retention and the selectivity of

alumina. If exposed to water, the retention

times will shorten. The column can be regen-

erated by conditioning for 15–30 minutes at

200 °C under normal carrier gas flow. Periodic

conditioning ensures excellent run-to-run

retention time reproducibility.

Unless noted, the maximum programmable

temperature for an Rt®-Alumina BOND

column is 200 °C. Temperatures higher than

the stated maximum temperature can cause

irreversible changes to the porous layer

adsorption properties.

similar phases

GS-Alumina, CP-Al

2

O

3

/Na

2

SO

4

,

Alumina-Sulfate

30-Meter

50-Meter

ID

df

temp. limits

cat.#

price

cat.#

price

0.25 mm 4 µm to 200 °C

19775

—

0.32 mm 5 µm to 200 °C

19757

19758

0.53 mm 10 µm to 200 °C

19755

19756

also

available

Metal MXT®

PLOT Columns

See

page 129.

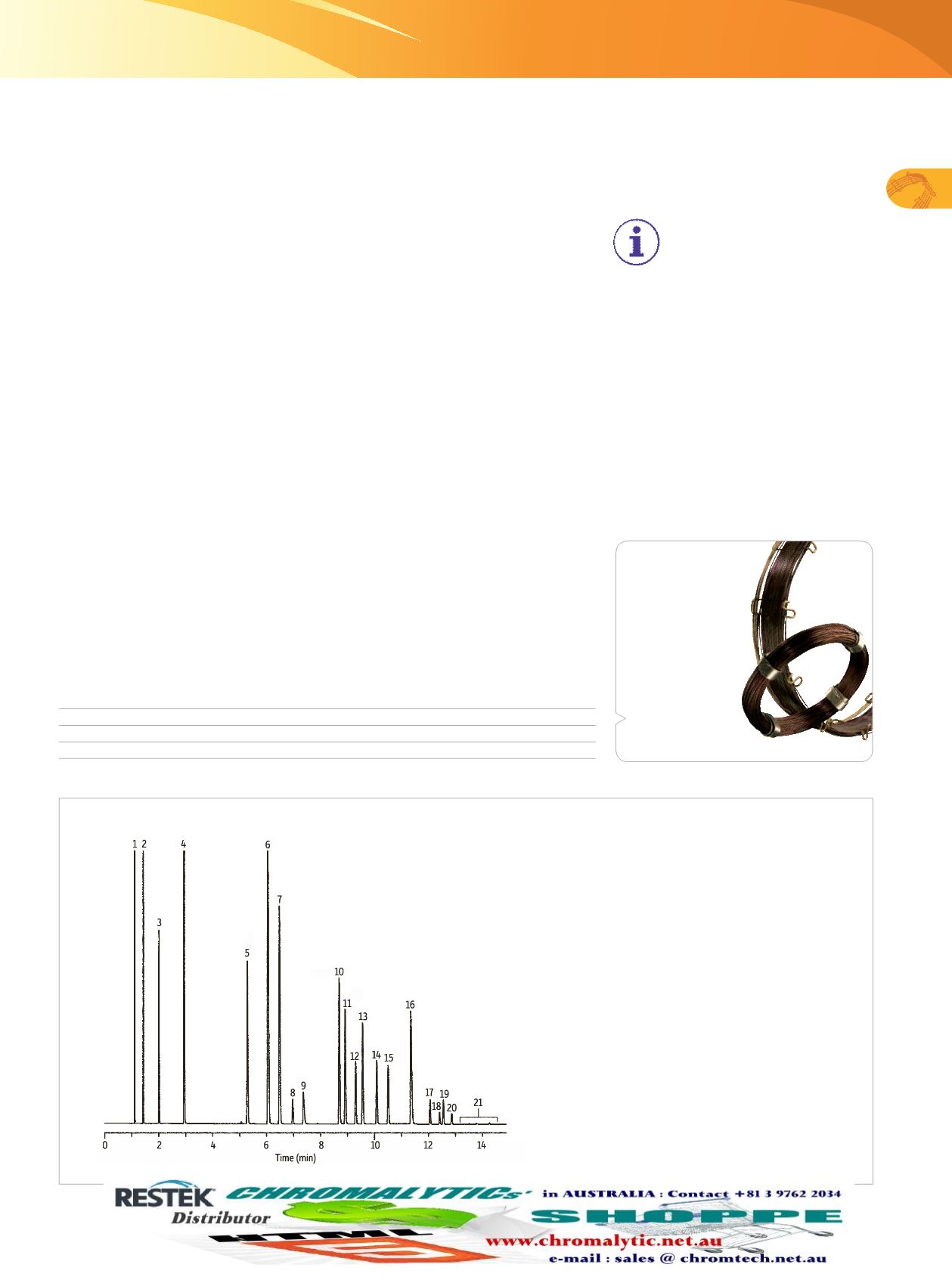

Refinery Gas on Rt®-Alumina BOND (Na

2

SO

4

)

GC_PC01085

Column

Rt®-Alumina BOND/Na

2

SO

4

, 50 m, 0.53 mm ID, 10 µm

(cat.# 19756)

Sample

Refinery gas

Injection

Inj. Vol.:

10 µL split

Liner:

Taper (2 mm) (cat.# 20795)

Inj. Temp.:

200 °C

Split Vent

Flow Rate:

80 mL/min

Oven

Oven Temp.:

45 °C (hold 1 min) to 200 °C at 10 °C/min (hold 3.5 min)

Carrier Gas

H

2

, constant pressure (8.0 psi, 55.2 kPa)

Linear Velocity:

74 cm/sec @ 45 °C

Detector

FID@ 200 °C

Peaks

1. Methane

2. Ethane

3. Ethylene

4. Propane

5. Propylene

6. Isobutane

7.

n

-Butane

8. Propadiene

9. Acetylene

10.

trans

-2-Butene

11. 1-Butene

12. Isobutylene

13.

cis

-2-Butene

14. iso-Pentane

15.

n

-Pentane

16. 1,3-Butadiene

17.

trans

-2-Pentene

18. 2-Methyl-2-butene

19. 1-Pentene

20.

cis

-2-Pentene

21. Hexanes