petroleum& petrochemicals

Applications

note

Restek Corporation • (800) 356-1688 • (814) 353-1300 •

petroleum&petrochemicals

AHigh-TemperaturePolydimethylsiloxane-PhaseColumn for

ASTMD-6352-98SimulatedDistillationAnalyses:MXT

®

1HTSimDist

#59479

Stable to 430ºC.

Low bleed.

Long lifetime at high temperatures.

Symmetrical hydrocarbon peaks.

Consistent resolution and retention times.

Boiling point elution of hydrocarbons.

Polarity equivalent to existing liquid phases.

Simulated distillation perASTMD-6352-98 is used for determin-

ing the boiling point range distribution of petroleum distillate frac-

tionswith initial boiling points (BP) > 174ºC and final boiling

points < 700ºC at atmospheric pressure. High temperature SimDist

presentsmany challenges. The stationary phasemust meet rigid

resolution and retention time requirements, yet be stable at high

temperatures. Further, the polyimide protective coating on the

outer surface ofmost capillary columns has amaximumworking

temperature of about 380ºC.Above this temperature the polyimide

rapidly deteriorates.When repeatedly programmed to temperatures

above 400ºC, or allowed to cool below 50ºC, the aluminum sheath

onmost aluminum-clad fused silica columns separates from the

underlying fused silica surface. The tubing becomes extremely

brittle, and column lifetime is significantly shortened.

To conform to the critical criteria set forth byASTM, Restek

chemists have developed theMXT

®

1HTSimDist simulated distil-

lation column. TheMXT

®

1HTpolymer is a 100% polydimethyl-

siloxane (PDMS)material that is thermally stable to 430ºC,

requiresminimal conditioning, and is 100% crosslinked. The

MXT

®

1HTphase is coated onto highly deactivated stainless steel

tubing that has the inertness of fused silicawithout the temperature

limitations. TheMXT

®

1HTSimDist column has a lifetime of at

least 400 injections under typical SimDist conditions.

To demonstrate the robustness ofMXT

®

1HTSimDist columns,

wemade a series of 400 injections of Polywax

®

1000 (cold on-col-

umn, CS2 solvent, 1µLeach) onto a randomly chosen column, and

monitored critical performance characteristics over the course of

these injections: resolution, retention times, stationary phase bleed.

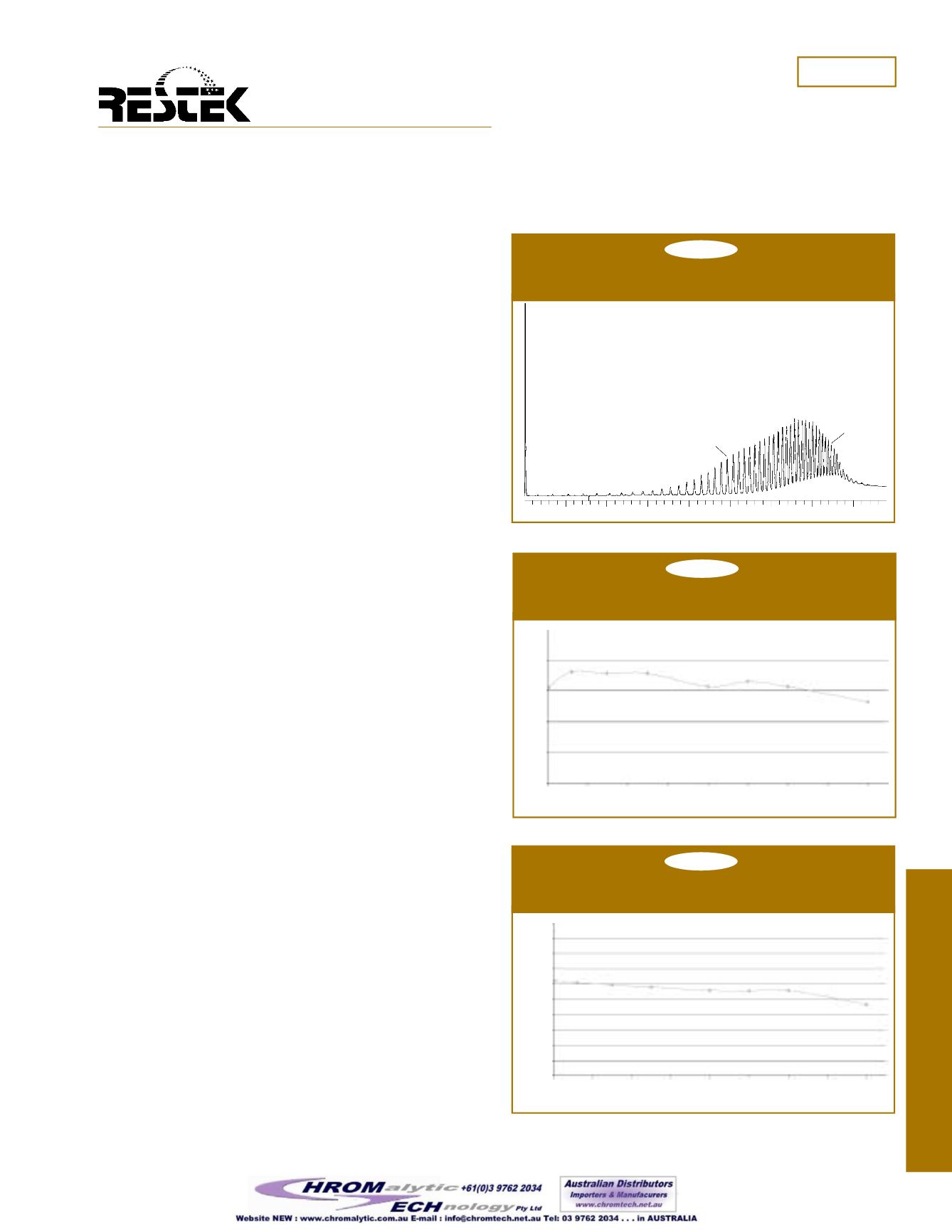

Figure 1 illustrates the Polywax

®

1000 analysis after 400 injec-

tions. The hydrocarbon components still arewell resolved and are

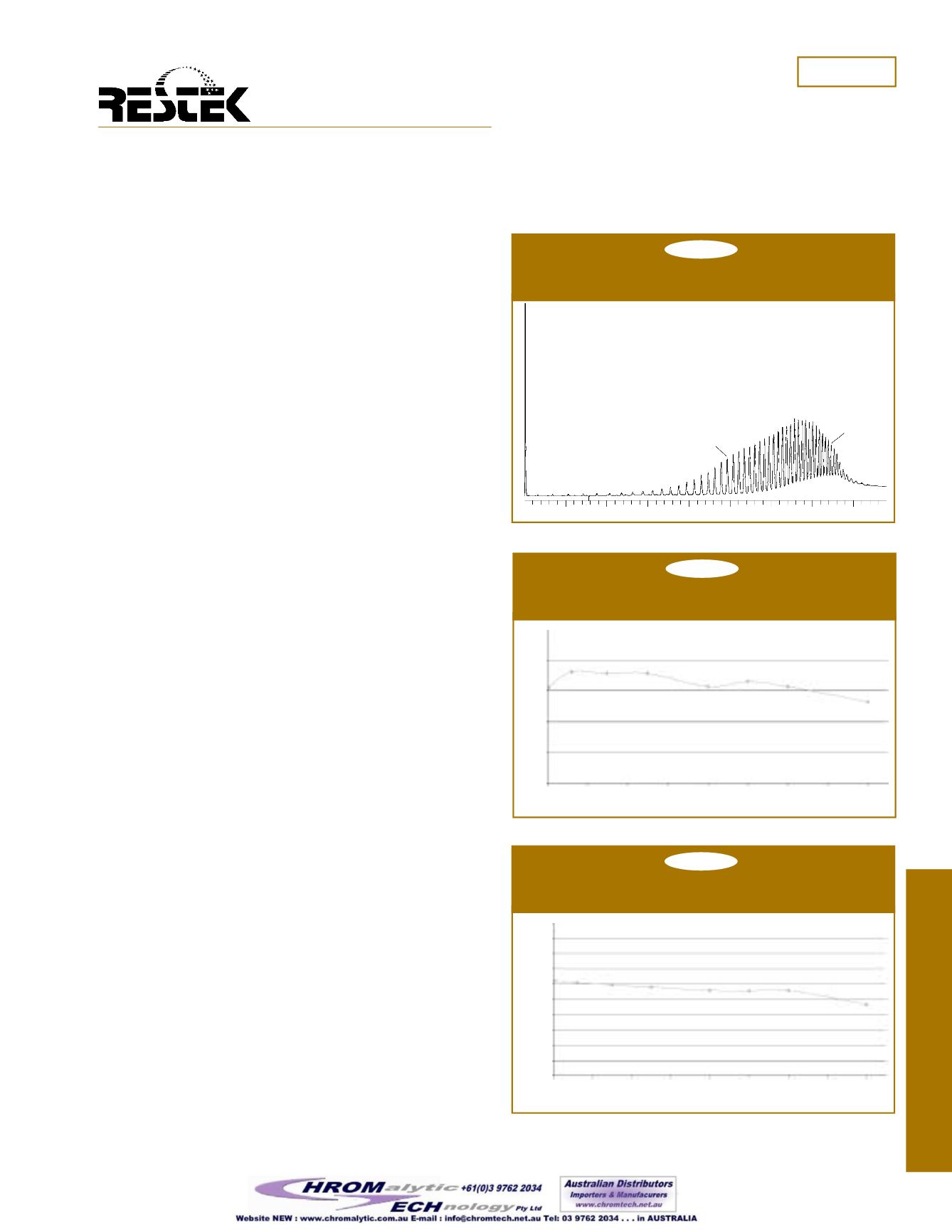

easily quantified. Figure 2 plots the reproducibility of C50/C52

resolution and Figure 3 shows retention time reproducibility.After

400 injections, both of these critical characteristics still meet simu-

lated distillation specifications. Figure 4 plots the consistently low

bleed at 430ºC over the series of 400 injections.

The stainless steel tubing used tomakeMXT

®

1HTSimDist

columns incorporates state-of-the-art Sulfinert™ deactivation. The

deactivation layer is incorporated into the framework of atoms on

the tubing surface, and thereforewill not fracture or flake off, even

if the column is flexed or bent.MXT

®

1HTSimDist columns do

not exhibit higher selectivity toward aromatics than toward normal

hydrocarbons, thus they provide true boiling point values.

Figure 1

Polywax

®

1000 hydrocarbonswell resolved on an

MXT

®

1HT SimDist column after 400 injections.

Figure 2

C50/C52 resolution is stable over a series of 400

injections on anMXT

®

1HT SimDist column.

5

10

15

20

25

30

35

40

C50

C100

4

3

2

1

0

400

350

300

250

200

150

100

50

0

ColumnResolution

5

Cycle #

C52RetentionTime (minutes)

30

29

28

27

26

25

24

23

22

21

20

200

150

100

50

0

250 300 350 400

Cycle #

Figure 3

C52 retention shows little change after 400 injections

on anMXT

®

1HT SimDist column.