environmental

Applications

note

Restek Corporation • (800) 356-1688 • (814) 353-1300 •

#59457

Fast Analysesof Aroclor

®

PCBs,Using theZipScientificGCRacer*

TemperatureProgrammingSystem

environmental

Introduction

Analytical chemists using traditional gas chromatographs (GC)

have control of four fixed parameters (column length and internal

diameter, phase type and film thickness) and three variable param-

eters (carrier gas composition and velocity, and temperature pro-

gramming) that affect analytical run times. Themaximum oven

temperature ramp rate has been limited, however, based on chro-

matograph design. Now, the temperature-programming rate can be

effectively increased, significantly shortening analysis time for

Aroclor

®

PCBs and thereby reducing instrument operating time

and increasing sample throughput.

Aroclor

®

PCBs

Aroclor

®

mixtures aremixtures of polychlorinated biphenyl (PCB)

congeners, each phenyl ring of which contains 1–5 chlorine atoms.

Since each PCB can contain up to 10 chlorine atoms, in any com-

bination of positions, there are 209 PCB congeners. Environmental

samples are commonly screened for sevenAroclor

®

mixtures that

are or werewidely used, but there are otherAroclor

®

mixtures and

PCBmixtures are alsomanufactured under other tradenames.

The seven commonly analyzedAroclor

®

mixtures areAroclor

®

1016, 1221, 1232, 1242, 1248, 1254, and 1260. OtherAroclor

®

mixtures include “technical”Aroclor

®

1254,Aroclor

®

1262, and

Aroclor

®

1268. TheAroclors

®

containmixes of congeners based on

distillation fractions. The last two digits of theAroclor

®

number

indicate the content of chlorine, byweight (e.g.,Aroclor

®

1232 is

32% chlorine byweight). The exception isAroclor

®

1016, which is

similar toAroclor

®

1242. The range of PCB congeners differs

amongAroclor

®

mixtures (e.g.,Aroclor

®

1242 ismade upmainly

of congeners ranging from approximately dichlorobiphenyls to

tetrachlorobiphenyls; late elutingAroclor

®

1260 ismade upmostly

of hexachlorobiphenyls to octachlorobiphenyls) and, since the

mixturesweremade toweight percent chlorine, not to specific

composition standards, the exact mixture of congeners varies

among variousmanufacture lots.AllAroclor

®

mixtures have some

PCB congeners in common, so retention times amongAroclor

®

mixtures overlap, but eachAroclor

®

mixture has an identifiable fin-

gerprint pattern.

ReducingAnalysisTime

Because the chromatographic patterns of the variousAroclor

®

mix-

tures are easily differentiated, the chromatographer could acceler-

ate theGC analysis, and thereby accomplishmore analyses during

a set period of time. To reduce analysis timewithout changing the

column, the chromatographer has three options: change carrier gas

(from helium to hydrogen), increase the velocity at which the car-

rier gas passes through the column, or increase the oven tempera-

ture program rate.

Changing the carrier gasmight not be a practical option. To

increase the velocity of the carrier gas the backpressure at the col-

umn inlet must be increased. Generally, 30m x 0.32mm columns

are operated at a pressure of 5-10psig, but the pressure can be

increased to 25 psigwithout a loss of column efficiency that would

affectAroclor

®

quantification.

The third option, increasing the oven temperature program rate, has

been a problem until now: oven temperature ramp rates are limited.

Most older chromatographmodels have amaximum reliable pro-

gramming rate of 20°C/minute; newermodels allow programming

rates of up to 70°C/minute, but only to relatively lowmaximum

temperatures.

Now, by using the Zip ScientificGCRacer auxiliary heating unit,

temperature program rates of up to 70°C/min. can bemaintained to

temperatures up to 350°C—conditions that allow analyses of

Aroclor

®

PCBmixtures to be accelerated.

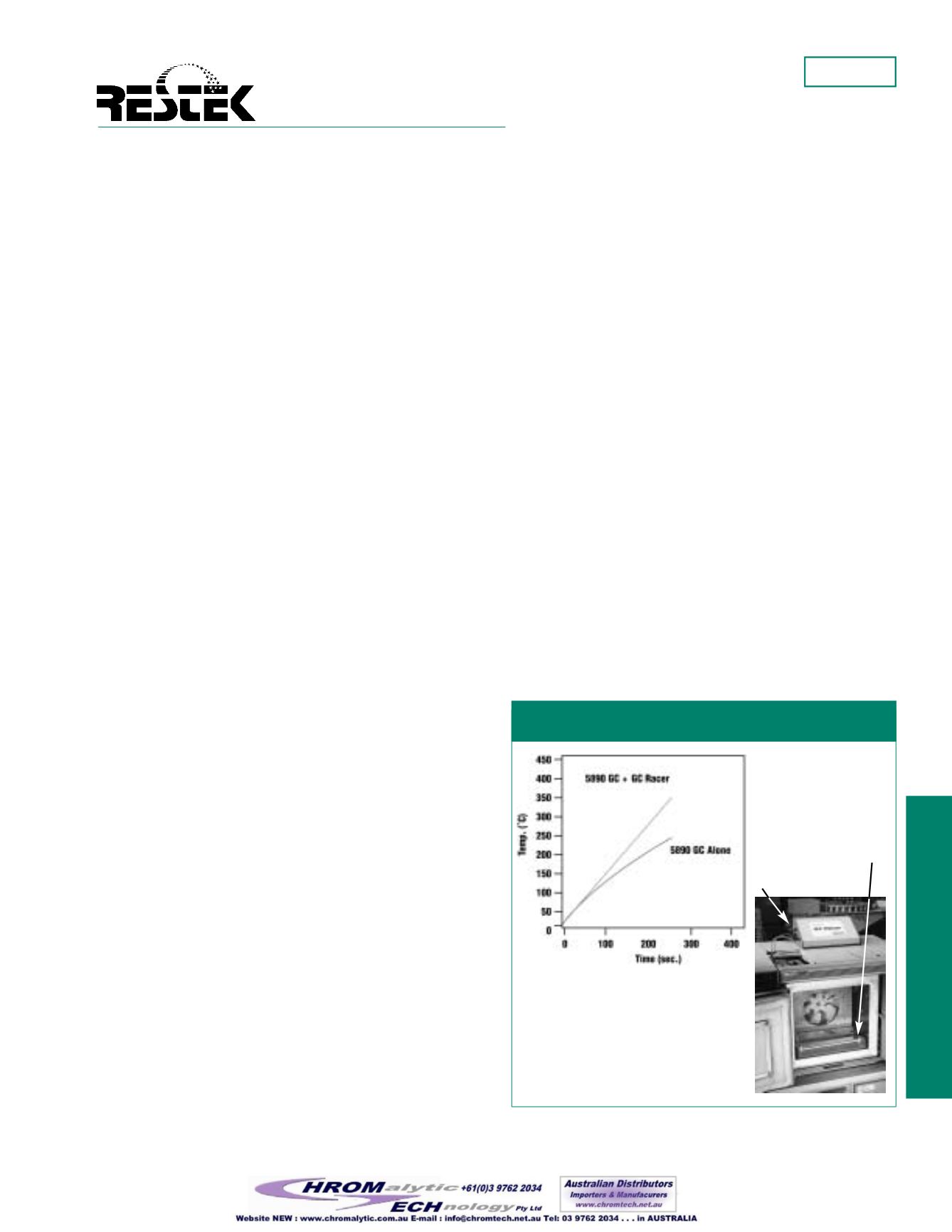

TheGCRacer consists of a program controller and a resistive heat-

ing element that is placed on the floor of theGC oven (Figure 1).

The heating element is connected to the controller which, in turn,

is plugged into themain PC board of theGC.When theGCRacer

programmer detects that the factory heating elements are not keep-

ing upwith the programmed heating rate, theGCRacer heater is

brought into the circuit to augment the heat being supplied to the

oven. Oven temperaturewith andwithout supplementation from a

GCRacer has been empirically testedwith anAgilent 5890 chro-

matograph; results are shown in Figure 1.

Faster Aroclor

®

Analyses

Figure 1—TheGCRacer allows a temperature program

rate of up to 70°C/min. tobemaintainedup to 350°C.

GC:

Agilent 5890;

Service:

120V/15 amp;

Start Temp:

20°C; set oven to 400°C and

monitor oven temp.

The GCRacer consists of a

control unit and a resistive

heating element placed on

the floor of the GC oven.

*Patent pending.

control unit

heating

element