506

O

OVENS

300°C Forced Air

Features:

The outer cases are fabricated from corrosion resistant zinc coated mild steel & finished in two tone hard

wearing stoved epoxy/polyester coating. The inner case is constructed from polished stainless steel. All units are

provided with non-tilt bright nickel wire plated shelves with multi-position settings for convenient loading & unloading.

Adjustable air ventilation

The chamber ventilation and exhaust vent are easily adjustable from the front control panel, on all bench top models.

Digital temperature control

The control module is able to house many variations of digital instrumentation with simultaneous display of measured

and set temperature. Microprocessor based PID controllers are fitted as standard.

Economy and efficiency

Insulation around the oven chamber utilizes totally encased fibre material. This material has a very low thermal mass

and thermal conductivity, ensuring very efficient insulation. This also ensures reduced holding power, making the units

economical to operate once set temperature has been reached.

Door action

A flush fitting door latch with a concealed mechanism is both simple to use & provides a handle when unlatched. The

lever action ensures gentle closure. The door seal design includes a newly formulated silicone compound, providing

longer life & durability at maximum temp. The design also allows convenient replacement if necessary.

This modern range of ovens provides a combination of excellent performance &

reliability. Increased power and low thermal mass encased fibre insulation

ensure both fast heat up times & reduced recovery times. Reduced holding

power once at set temp., together with the insulation, makes the range

economical & outer case temperatures have been significantly reduced.

Both gravity & forced air circulation models are available with a wide choice of

control options allowing the most critical performance criteria to be met. Where

processes involve the liberation of flammable VAPORs, a stoving & curing option

is available. Also, where processes involve large amounts of water, a moisture

extraction option is available.

Note: A uniformity of ±1%=±1°C at 100°C *With vents closed.

PF-Series, 300°C Ovens

PF-30

Options:

●

Range of over temp. protection

systems in accordance with DIN12-880

Part 2.

●

Stoving & curing option available for

processes involving liberation of

flammable vapors.

●

Timers: Process timers-manual or

automatic. Mechanical or electronic

time switches.

●

Top access port for independent

probe.

●

Lockable door latch.

●

Exhaust fan *

●

Variable speed fan *

●

Inert gas connection *

●

Flow meter & needle valve.

●

Viewing window in door *

●

Interior light.

●

Air inlet filter.

●

Cable entry port *

●

Door switch.

●

Stands & trolleys.

●

Chart recorders.

* These options may affect Chamber Uniformity

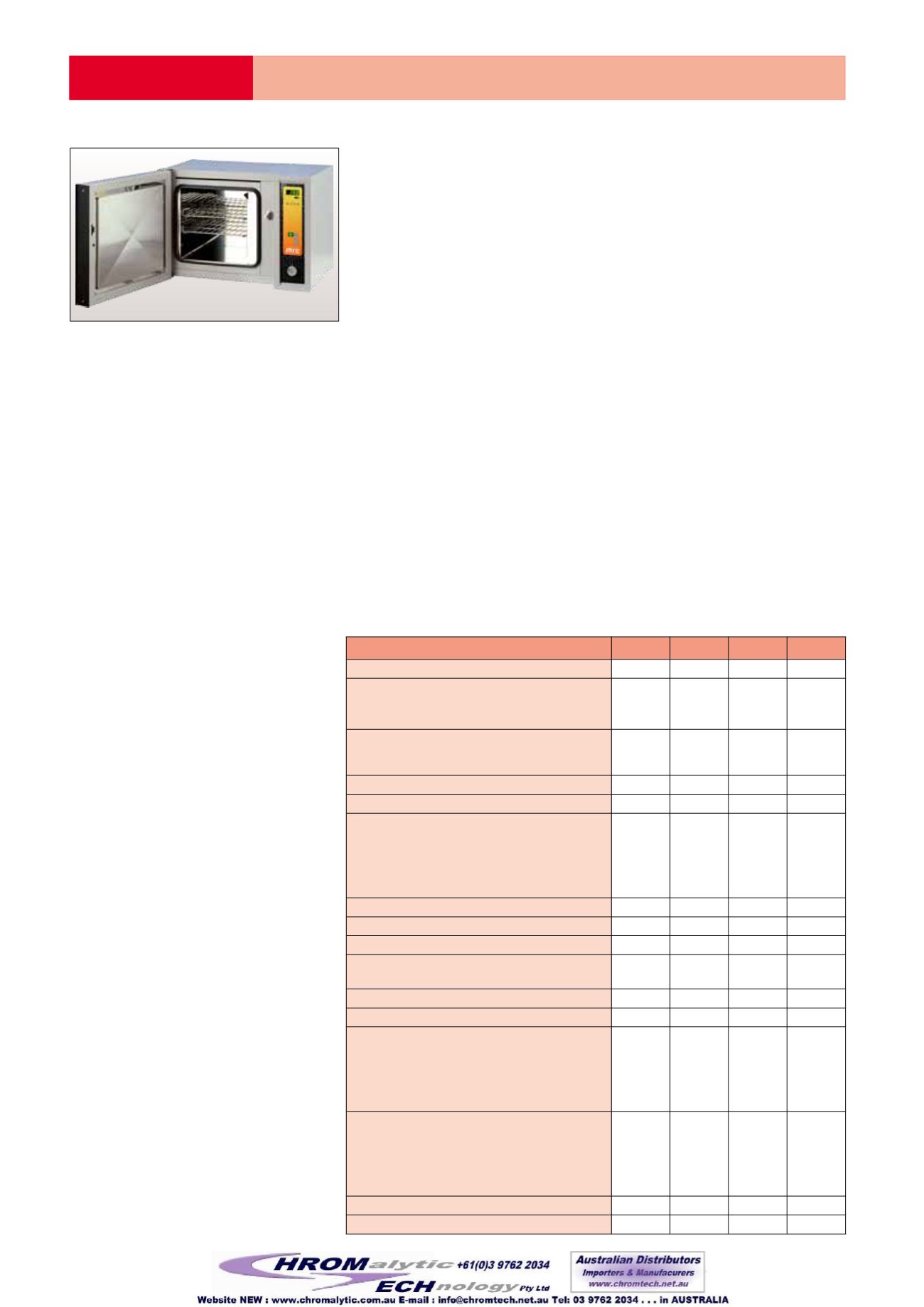

Model

PF30 PF60 PF120 PF200

Max. Temp (

O

C)

300

300

300

300

(H)

Chamber Dimensions (W)

(mm) (D)

300

292

320

400

392

420

500

492

520

750

592

520

(H)

Outside Dimensions (mm) (W)

(D)

470

665

470

570

765

570

670

865

670

920

965

670

Chamber Capacity (Liters)

28

66

128

230

Weight (kg)

30

45

60

75

Shelves

Number Supplied

Max. Possible

Max. Dist load/shelf kg

Max load kg

2

3

10

20

2

5

10

30

2

9

10

40

2

15

10

50

Performance

Power Rating at 240V (watts)

1000 1500 2000 2700

Holding Power* at Max. temp. (watts)

350

600

800 1250

Temp. Uniformity*

(at Max. temp. as a%)

±1.0 ±1.0 ±1.0 ±1.0

Temp. Stability on/off control (

O

C)

±1.0 ±1.0 ±1.0 ±1.0

Temp. Stability PID control (

O

C)

±2.0 ±2.0 ±2.0 ±2.0

Heat up Times* 100

O

C

(Mins)

200

O

C

240V

300

O

C

4.5

12

25

4.5

12

25

4.5

12

25

5.5

14

30

Recovery Times* 100

O

C

(Mins)

200

O

C

Door Open 60sec 300

O

C

240V

1

2.5

4

1

2.5

4

1

2.5

4

1.5

3

5

Air Exchanges vol (l/h) @ 100

O

C

1400 1400 1400 1400

Air Exchanges

50

21

11

6

Control panel

The side mounted control panel avoids

damage from accidental spillage.

Safety standards

All units meet the relevant European

health and safety at work legislation &

the performance criteria of BS 2648 &

DIN 50-011. They are manufactured to

comply with BS EN 61010: safety

standard & also the low voltage & EMC

European Directives.