498

M

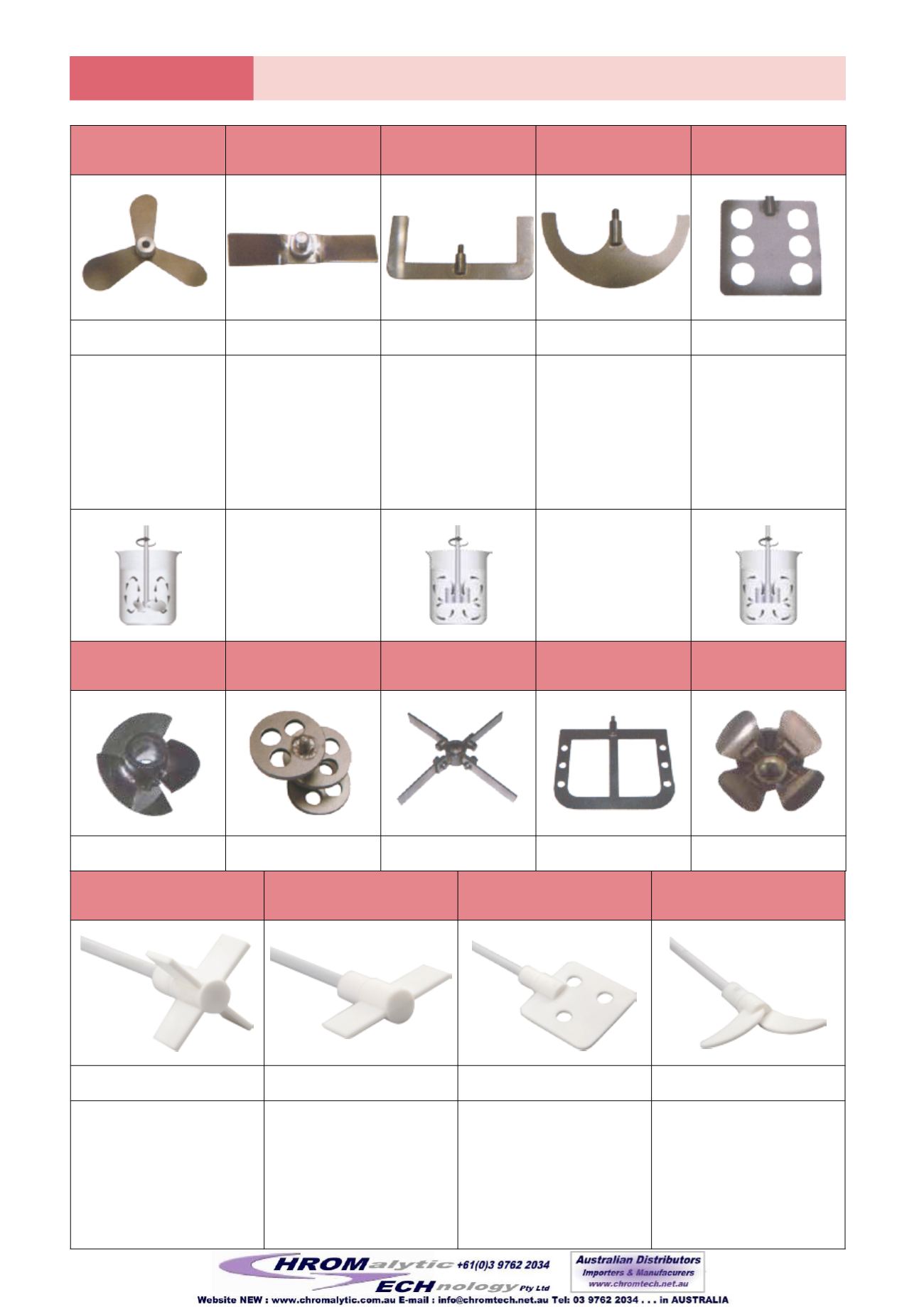

MIXERS

No.16

No.17

Centrifugal stirrer

No.18

Anchor stirrer

No.19

No.20

Paddle stirrer

Ø

8, 10, 12, 16, 20cm

Ø

5cm

Ø

5, 7, 7.5, 8, 11cm

Ø

9.5cm

Ø

7cm

Flow-efficient design

for drawing the

material to be mixed

from the top and

the bottom while

creating minimum

shearing forces. This

propeller stirrer is used

at medium to high

speeds.

Two-bladed, blades

open with increasing

speed. For stirring in

round vessels with

narrow necks. Effect

is similar to that of a

4-bladed propeller

stirrer. Medium to high

speeds required.

Tangential flow, high

shearing rate at edges,

minimum deposits on

the vessel wall. Used

at low speeds. Polymer

reactions, even

distribution of high

mineral contents in

liquids. The ideal stirrer

for medium to highly

viscous fluids.

-

Tangential flow,

minimum turbulence,

good heat exchange,

gentle treatment of

product. Used at low

to medium speeds.

For applications of

gentle treatment of

materials.

-

-

No.21

No.22

No.23

No.24

No.25

Ø

3cm

Ø

2.5, 4cm

Ø

14cm

Ø

10cm

Ø

4cm

Impellers

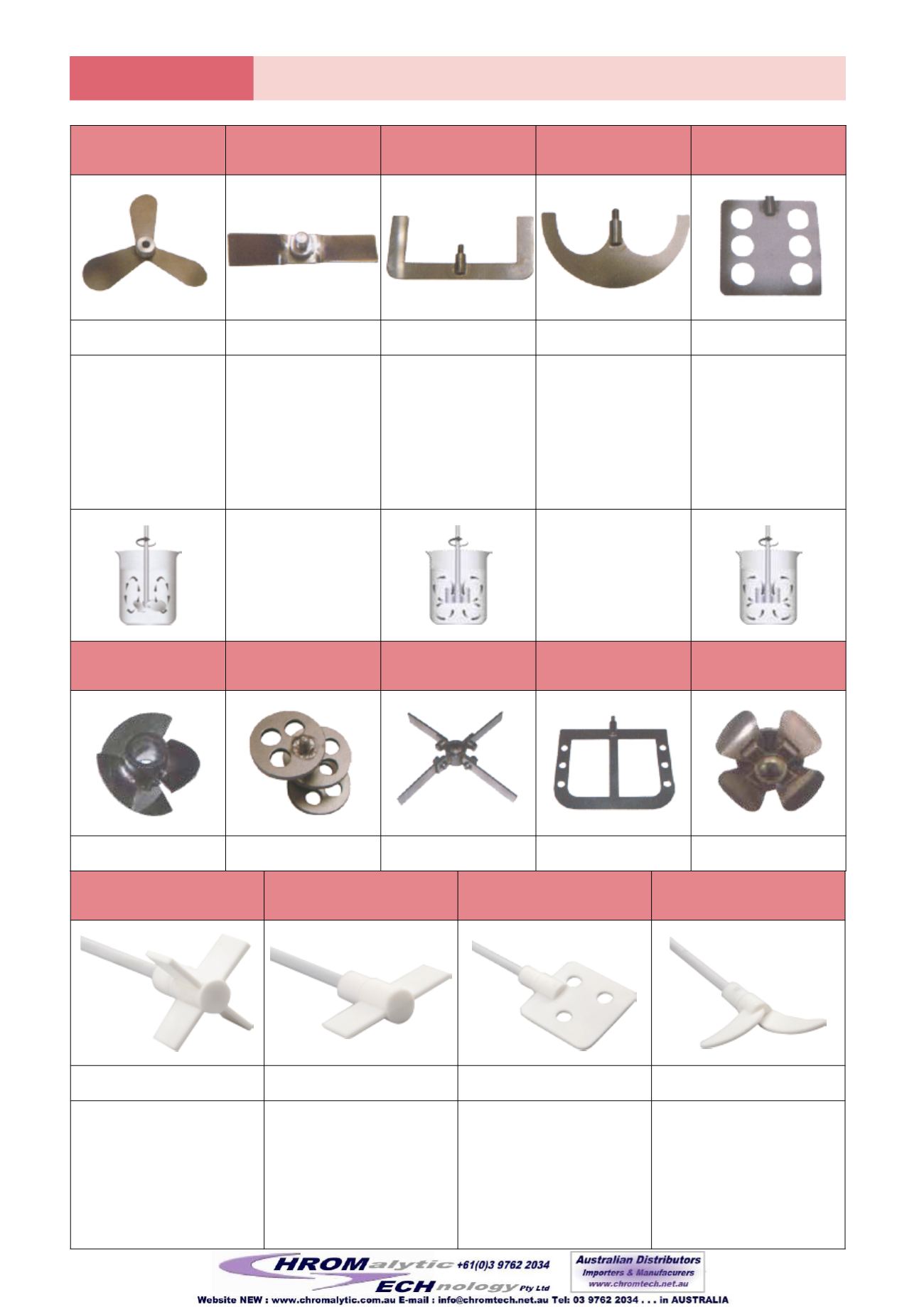

No.26

No.27

No.28

No.29

Ø

6.5cm

Ø

7cm

Ø

6.8cm

Ø

8.5cm

Crossed stirrer,

shaft length 35cm,

PTFE coated.

Standard stirring

element, used at

medium and high speeds

Straight stirrer,

shaft length 35cm,

PTFE coated.

Suitable for mixing of low

viscosity media, used at

medium and high speeds

Blade stirrer,

shaft length 35cm,

PTFE coated.

Gentle processing

samples, used at low

and medium speeds

Centrifugal stirrer,

shaft length 35cm,

PTFE coated.

Blades open with increasing

speed for stirring in a

round vessel with a narrow

neck, used at medium and

high speeds