PA2000i Measuring Channels

ANALYZERS

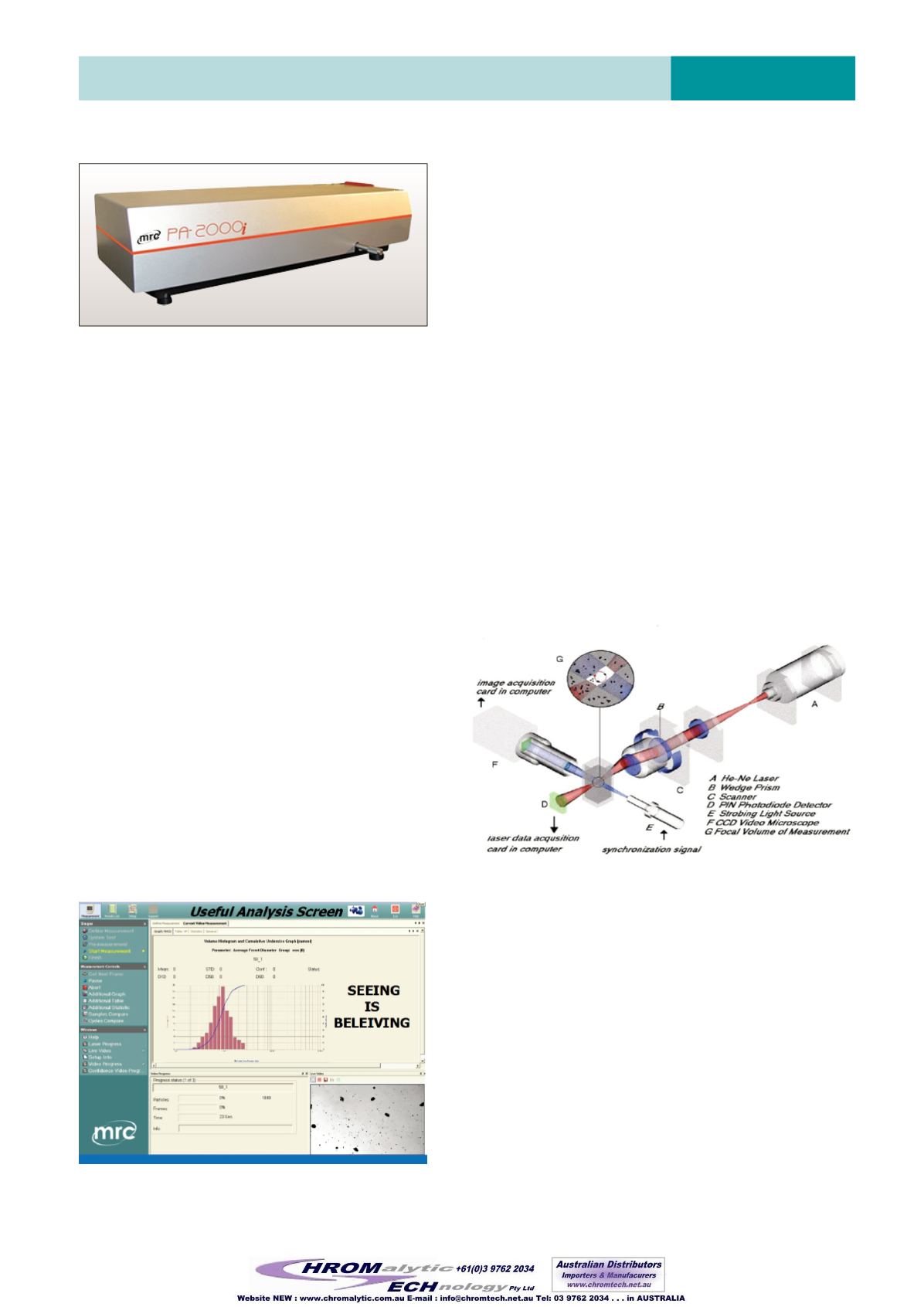

The PA2000i Laser Channel is a straight-forward technique

for determining micro-particle size distribution

(0.1 - 3,600 microns), without any assumptions or sample

pre-knowledge.

This unique analytical technique is called “Laser

Obscuration Time” (LOT).

The major advantage of direct particle size measurement

over other laser used techniques is its higher resolution

obtained by the individual particle measurement

approach that allows minor fraction detection and better

measurement accuracy.

Main benefit of using the LOT is that the analysis results

aren’t affected by any physical or chemical property of

the particle or its medium, enabling reliable results.

State-Of-The-Art software analyses the obscuration time as

multiple pulses algorithm complex, providing within seconds

clear and accurate particles size distribution results.

The PA2000i Video Channel performs 2-D particles

Dynamic Size and Shape Analysis in a wide size

range (1 - 5,000 microns).

Acquired images are displayed and analyzed by

powerful image analysis software and are

automatically processed and analyzed while dozens

of useful analytical parameters of the sampled

particles are efficiently determined.

User friendly software provides automated and

advanced Image Analysis features that assist in

optimizing sample measurement.

Software algorithms enable automatic

pre-programmed calculation for all of the available

parameters including Ferret diameter, area,

perimeter, circularity, aspect ratio and many other

useful size and shape analytical parameters.

This remarkable S/W can be used also in a

stand-alone microscopy application, when a

compatible CCD camera is mounted on an optical

microscope, and the captured images are being

analyzed accordingly.

Magnetic Stirring, Mechanical Stirring, Liquid flow-through,

Fibre flow-through, Aerosol flow-through, Micro

Flow-through, Slide, Heated, Free Fall.

The PA2000i On-Line measurement offer analytical solutions

for a wide variety of applications and processes in-line,

in-sito, in pilot plants, in reactors or in the lab: grinding,

crystallization, polymerization, homogenization, filtration,

separation, drying, dispersion and so on.

●

Pre-Processing Procedures

●

Image Quality Filters

●

Region of Interest Determination

●

Out-Of-Focus Rejection

●

Morphology Operations

●

Grouping according to size/shape

●

Re-Processing of captured images and movies

●

Manual Lens Calibration for External Installations

Real images of the measured particles can be easily

saved and printed separately or added directly into

the analysis report document.

Particle Size & Shape Analyzer

PA2000i, Particle Size & Shape Analyzer

Laser Channel - High Resolution & Accuracy

PA2000i

Video Channel - Dynamic Image Analysis

Measurement Cells:

PA2000i Image Analysis software includes many

procedures such as:

270