Active

Debubbler

Debubbler/

Degasser

Transfer-LineDegasser

Systec

®

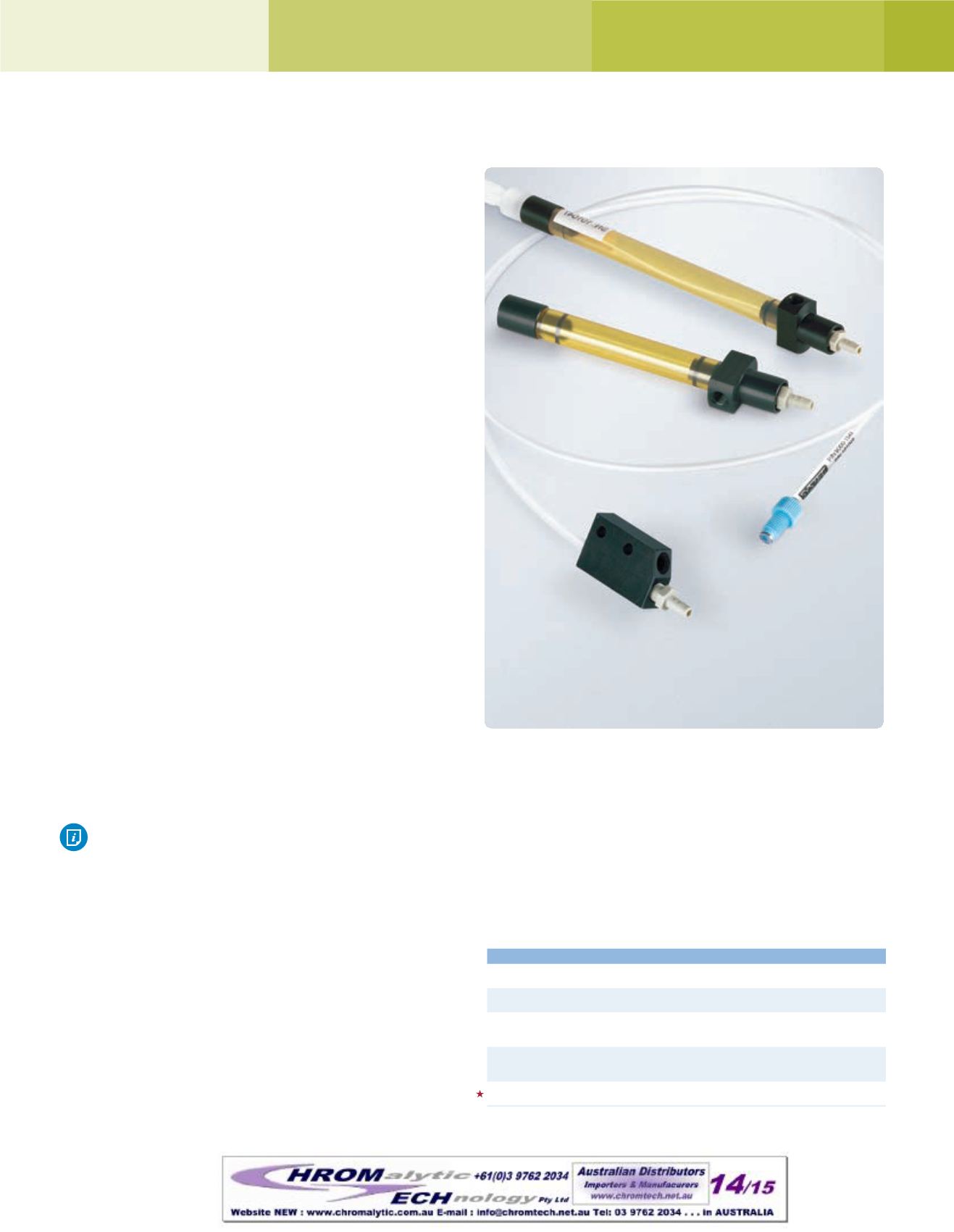

DebubblerSeries

RemoveBubbles,DissolvedGas, orBoth!

Dissolvedgasesandbubbles insystem liquidscausedispensevolume

anomalies inmany instruments, negatively affectingbothdispense

precisionandanalyticalaccuracy.Nowyouhaveachoiceofcomponents

foractively removingbubbleswithorwithoutalso removingdissolved

systemgases.OnlineVacuumDegassingoffersoperatingconvenience,

highefficiency and lowoperating costs compared toother common

degassing technologies.

Debubbler/Degasser

Combines VacuumDegassingwithActiveBubbleRemoval

XX

Improves instrument performance— reducesdowntimedue to

bubble formation.

XX

Fewer falsepositivesdue to reductionof partial reagent dispenses.

XX

Easily integrates intoanypump, degassing tray, or stand-alone

degassingapplication.

ActiveDebubbler

RemoveBubbles in Fluid StreamBeforeor After thePump

XX

Improves instrument performance— reducesdowntimedue to

bubble formation.

XX

Fewer falsepositivesdue to reductionof partial reagent dispenses.

XX

Easily integrates intoanypump, degassing tray, or stand-alone

degassingapplication.

Transfer-LineDegasser

RemovesDissolvedGasesDuringFluidTransfer

XX

Eliminates baseline fluctuations for improveddetector sensitivity.

XX

Coaxial design reduces number of connections,

improves reliability.

XX

Single lumendesign increases degassing reliability.

APPLICATIONNOTE

Inmedical analyzers, bubbles interferewithcritical volumetric reagent

dispensesandcause sample failures,wasting timeandmoney. Because

bubblesadhere tonearlyeverypart of adispensing system, high velocity

or induced turbulent flow isoftenused todisplaceanddischarge

bubbles from theflow streamand intoawastearea. Thesealternative

processeswaste reagentsandare timeconsuming, unpredictable, and

mayadditionally requiredesigning the system to recognizebubblesare

present. Regardlessof how the systemsaredesigned, aqueous systems

will alwaysbe subject to the lawsof physics that causeout-gassing

duringchanges influid temperature, pressure, or chemicalsmixture.

Influidapplications like these, debubblersare theoptimal solution

tocaptureand remove formedbubbles toprevent sampledispense

inaccuracies, anddegassing is ideal topreventdownstreambubble

formation from recurring.

XX

Liquidhandling

XX

IVD

XX

HPLC/UHPLC

XX

O

2

andCO

2

removal

PartNo.

Description

Standard

Bubble

TrapSize

Transfer

Line

Length Internal Volume

Max

Bubble

Capacity

DEBUBBLERSERIES –AVAILABLESTANDARDCONFIGURATION

9000-1540

2.5mLActive

Debubbler

2.5mL

— 2.5mL

2.5mL

9000-1541

5mLActive

Debubbler

5mL

— 5mL

5mL

9000-1544

2.5mL

Debubbler/

Degasser

2.5mL

17.5”

(444.5mm)

2.5mL in transfer

line+2.5mL in

bubble trap

2.5mL

9000-1545

5mLDebubbler/

Degasser

5mL

34”

(863.6mm)

5mL in transfer

line+5mL in

bubble trap

5mL

9000-1549

1.1mTransfer-

LineDegasser

—

1.1m (43”)

4mL

N/A

DEBUBBLERS&DEGASSERS

175

Debubbler Series