www.restek.com

www.restek.com

|

1-800-356-1688

or

1-814-353-1300

| Feedback? E-mail

advantage@restek.com21

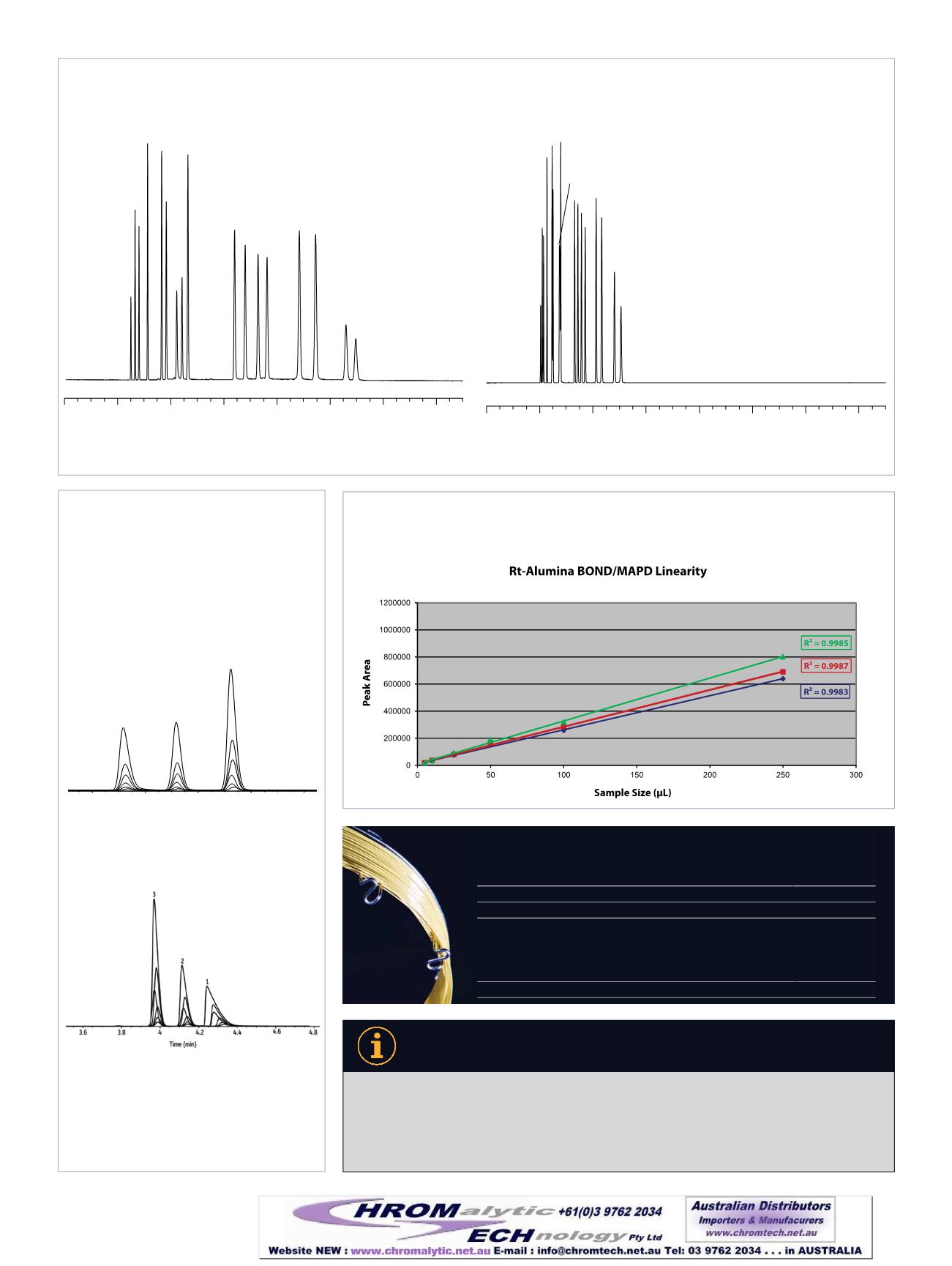

Figure 2:

Higher sample capacity is also

demonstrated by comparing peak sym-

metry. Rt®-Alumina BOND/MAPD col-

umns produce better peak shape, even

when more material is injected.

4.2

4.4

4.6

4.8

1

2

3

4

Time (min)

Figure 1:

Rt®-Alumina BOND/MAPD columns have greater absolute retention than Select Al

2

O

3

MAPD columns, resulting in greater sample

handling capacity through increased resolution.

Time (min)

2

0

4

6

8

10

12

14

9

10

11

12 13

14 15

16

17

5

6

7

8

1

2

3

4

GC_PC1213

min.

0

2

4

6

8

10

12

14

9

10 11

12

13

14

15

16

17

5

6

7,8

1

2

3

4

GC_PC1214

Columns:

50 m x 0.53 mm ID x 10 µm;

Sample:

PLOT column QA test mix (DCG# 547267);

Injection:

5 µL, split, 200 °C; Split vent flow rate: 80 mL/min;

Oven:

130 °C, isothermal;

Carrier Gas:

helium, (4.4 psi, 30 kPa);

Detector:

FID, 200 °C.

Peaks:

1. Methane, 2. Ethane, 3. Ethylene, 4. Propane, 5. Cyclopropane, 6. Propylene, 7. Acetylene, 8. Propadiene, 9.

n

-Butane, 10.

trans

-2-Butene, 11. 1-Butene, 12. Isobutene, 13.

cis

-2-Butene, 14.

Isopentane, 15.

n

-Pentane, 16. 1,3-Butadiene, 17. Methyl acetylene.

A: Rt®-Alumina BOND/MAPD

B: Select Al

2

O

3

MAPD

Higher retention results in greater

sample handling capacity and more

flexibility in sample size.

Higher sample capacity

gives good peak shape and

improved accuracy.

GC_PC1216

A: Rt®-Alumina BOND/MAPD

B: Select Al

2

O

3

MAPD

GC_PC1215

Columns:

50 m x 0.53 mm ID x 10 µm;

Sample:

PLOT column QA

test mix (DCG# 547267);

Injection:

5-250 µL, split, 200 °C; Split

vent flow rate: 80 mL/min;

Oven:

manufacturer’s recommended

temperature used for each column (Rt®-Alumina BOND/MAPD:

130 °C, Select Al

2

O

3

MAPD: 100 °C), isothermal (hold 8 min);

CarrierGas:

helium, (4.4 psi, 30 kPa);

Detector:

FID, 200 °C.

Peaks:

1. Acetylene, 2. Propadiene, 3.

n

-Butane.

Figure 3:

Higher sample capacity results in a wide linear range and accurate quantifica-

tion, even at levels that can produce tailing and incomplete separations on other MAPD

columns. (

green

= methyl acetylene,

red

= acetylene,

blue

= propadiene).

Traces of water in the carrier gas and sample will affect the retention and selectivity of alumina. If the column is exposed to

water, the retention times will shorten. Alumina columns can be regenerated by conditioning for 15-30 minutes at 200-250 °C

under normal carrier gas flow. Periodic conditioning ensures excellent run-to-run retention time reproducibility.

The maximum programmable temperature for Rt®- and MXT®-Alumina BOND/MAPD columns is 250 °C. Higher temperatures

cause irreversible changes to the porous layer adsorption properties.

tech

tip

Alumina BOND/MAPD PLOT Columns

Rt®-Alumina BOND/MAPD Columns

(fused silica PLOT)

MXT®-Alumina BOND/MAPD Columns

(Siltek®-treated stainless steel PLOT)

ID

df

temp. limits

30-Meter

50-Meter

0.32 mm 5 µm

to 250 °C

19779

19780

0.53 mm 10 µm

to 250 °C

19777

19778

3.5

”

coil

7

”

diameter

11-pin cage

ID

df

temp. limits

30-Meter

30-Meter

0.53 mm 10 µm

to 250 °C

79728-273

Poor sample capacity

results in overloaded

peaks and inaccurate

quantification.

79728