•

8

•

2007 vol. 3

Environmental

Faster Organochlorine Pesticide Sample Throughput

On New Rtx

®

-CLPesticides & Rtx

®

-CLPesticides2 Columns

By Jason Thomas, Environmental Innovations Chemist

• Dramatically improve sample throughput.

• Results in <7min. by conventional analysis, or <5min. using the Gerstel MACH system.

• Outstanding resolution on all columns.

As the environmental testing market continues to be very competitive, laboratory operating costs are a critical concern. Increasing

sample throughput is one way to reduce costs, and shortening analytical run time is an effective way to do this. Here we offer meth-

ods for reducing run time for the organochlorine pesticides analyzed under US EPA Method 8081. The significant reduction in both

analysis time and more significantly, cycle time, offered here is a major benefit for environmental laboratories.

Restek developed the Rtx

®

-CLPesticides and Rtx

®

-CLPesticides2 column pair specifically for chlorinated pesticides. These phases were

designed to separate the isomers and the structurally similar pairs on the list of target analytes. Here we introduce new film thick-

nesses with optimized phase ratios for some of the columns in this line. Using these new stationary phase film thicknesses and the

optimized run conditions shown, the 20 compounds in US EPA Method 8081 can be separated to baseline in less than 7 minutes

(Figure 1). This allows rapid analysis without sacrificing column capacity, which translates, of course, into much improved sample

throughput for your laboratory.

An Even Faster Alternative

In the attempt to obtain faster analytical run times, several different concepts have been introduced to improve the stock perform-

ance of standard GCs. One of the most recent and versatile ideas is the low thermal mass method by Gerstel using an apparatus

called the MACH, (Modular Accelerated Column Heater) (Figure 2). This system operates by heating the capillary column outside

of the GC oven in a small column module mounted on the oven door.

This apparatus provides several important advantages. First, due to the low thermal mass of the unit, very rapid heating and cooling

times can be realized, which significantly shortens cycle times. Second, because of the way the column is wrapped, very uniform

heating occurs, which eliminates the eddies and hot spots produced in a conventional GC oven. Finally, since the column modules

are independently controlled, two different temperature programs can be run simultaneously, which allows each column to be opti-

mized individually.

Restek applied this novel MACH technology to EPA Method 8081 using an Rtx

®

-CLPesticides and Rtx

®

-CLPesticides2 column pair.

Almost 100% baseline resolution was obtained for all 22 pesticides and surrogates, on both columns, in under five minutes (Figure

3). This combination of ultra-fast analysis time and outstanding resolution is a result of the unique selectivity and high efficiency of

the phases combined with the narrow peaks associated with ultra-rapid ramp rates.

Regardless of whether you choose to embrace the new fast-GC technology, or continue to adhere to more conventional GC, Restek

Rtx

®

-CLPesticides and Rtx

®

-CLPesticides2 columns can provide exceptional performance and very rapid run times when analyzing

chlorinated pesticides.

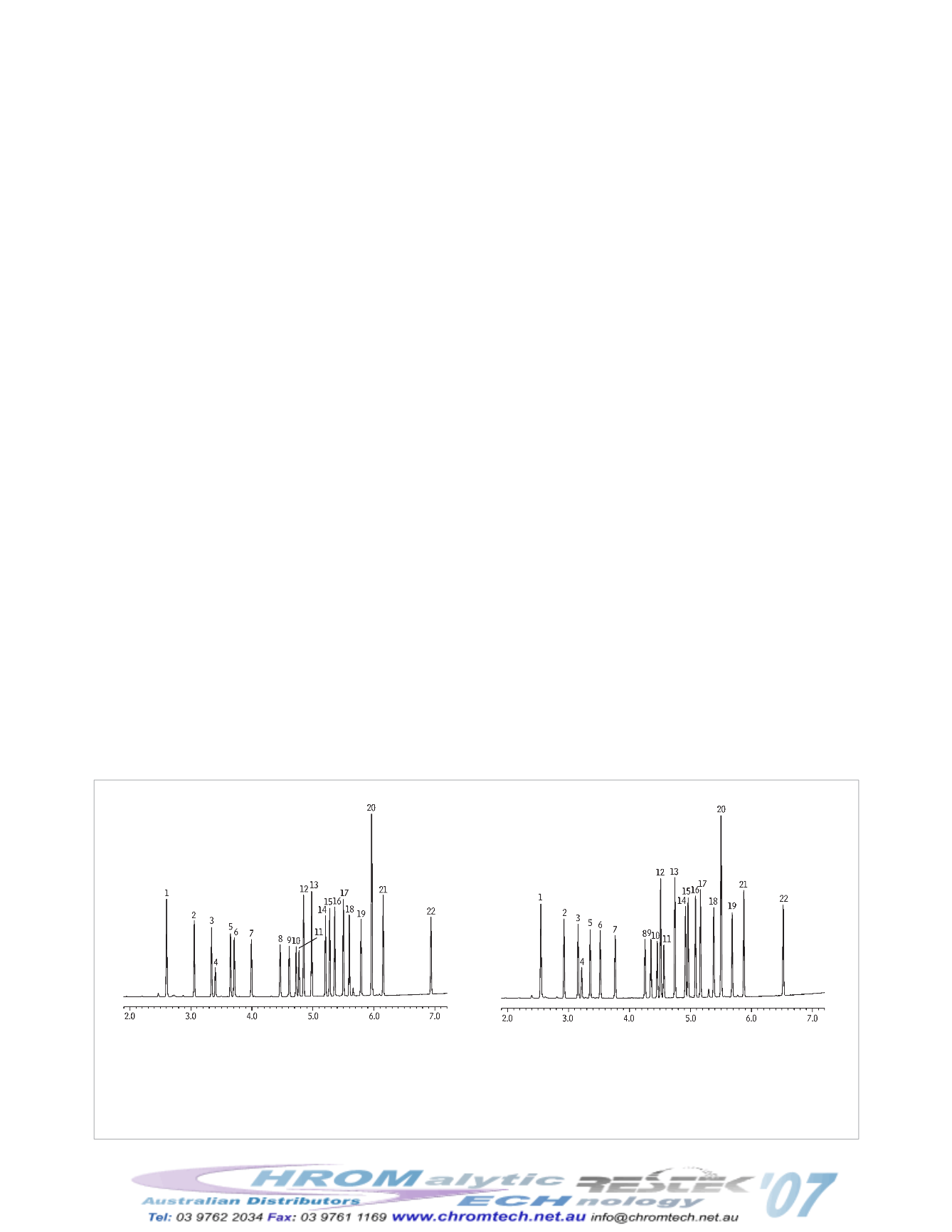

Figure 1

Baseline resolution of organochlorine pesticides on the 0.18mm ID Rtx

®

-CLPesticides column pair in less

than 7 minutes.

Column: Rtx

®

-CLPesticides 30m, 0.32mm ID, 0.32µm (cat.# 11141) and Rtx

®

-CLPesticides2 30m, 0.32mm ID, 0.25µm (cat.# 11324) with 5m x 0.32mm ID Rxi

™

deactivated guard tubing

(cat.# 10039), connected using Universal “Y” Press-Tight

®

connector (cat.# 20405-261)

Sample: Organochlorine Pesticide Mix AB #2, 8-80µg/mL each component in hexane/toluene (cat.# 32292), Pesticide Surrogate Mix, 200µg/mL each component in acetone (cat.# 32000)

Inj.: 1.0µL splitless (hold 0.3 min.), 4mm single gooseneck inlet liner (cat.# 20799); Inj. temp.: 250°C; Carrier gas: helium, constant flow; Linear velocity: 60cm/sec. @ 120°C; Oven temp.:

120°C to 200°C @45°C/min. to 230°C @15°C/min to 330°C (hold 2 min.) @ 30°C/min.; Det.: ECD @330°C

1. 2,4,5,6-tetrachloro-

m

-xylene (SS)

2.

α

-BHC

3.

γ

-BHC

4.

β

-BHC

5.

δ

-BHC

6. heptachlor

7. aldrin

8. heptachlor epoxide (isomer B)

9.

γ

-chlordane

10.

α

-chlordane

11. endosulfan I

12. 4,4'-DDE

GC_EV00933

GC_EV00933A

Rtx

®

-CLPesticides2

Rtx

®

-CLPesticides

13. dieldrin

14. endrin

15. 4,4'-DDD

16. endosulfan II

17. 4,4'-DDT

18. endrin aldehyde

19. endosulfan sulfate

20. methoxychlor

21. endrin ketone

22. decachlorobiphenyl (SS)

min.

min.

Baseline

resolution

in <7min.!