2007 vol. 4

Tech Tip

0

10

20

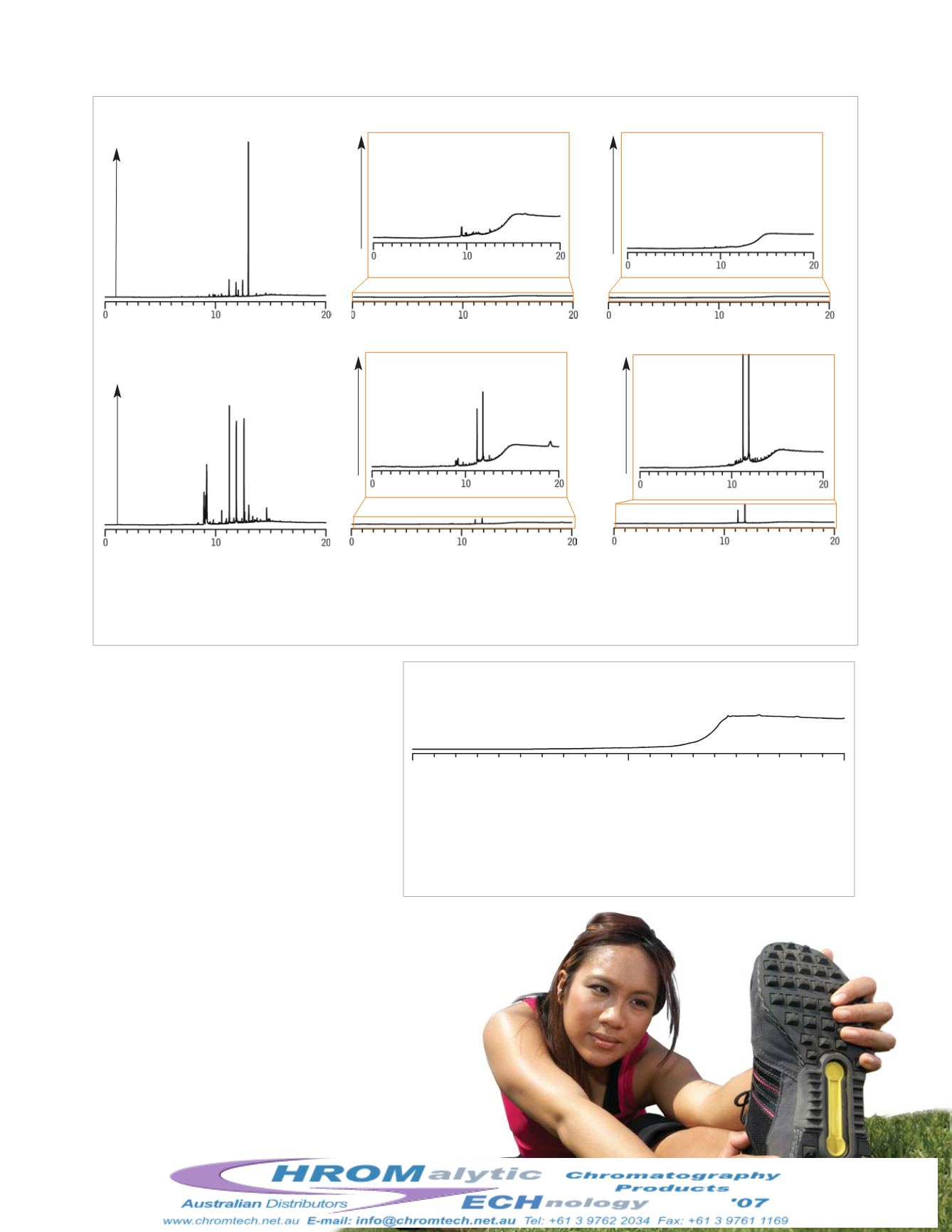

Figure 4

Conditioning your system above method temperatures is

an excellent way to remove contaminants.

advantage to this technique is that it doesn’t exert

any additional thermal stress on the system, which

may mean longer lifetimes for some parts, such as

inlet O-rings.

Another method is to elevate the thermal zones in

your instrument for a set period of time. The data

in Figure 4 show that a flat baseline is achieved

after just ten minutes of thermal conditioning. If

you use thermal conditioning, be sure to use pro-

gressively hotter temperatures along the sample

flow path. For example, your column should be

hotter than your inlet, and your detector should be

hotter than your column. This prevents condensa-

tion of contaminants in the system which can

appear as “ghost peaks” or poorly shaped peaks

that elute at irreproducible retention times.

Conclusion

We observed that no matter whose product you

buy, you can expect some background noise if you

install an inlet liner and immediately begin analy-

sis. However, these background peaks easily can be

eliminated by either a few warm-up runs or a brief

period of thermal conditioning. Before analyzing

valuable samples, take the time to warm up your

system, ensuring that you are ready to run!

Column:

Rxi

®

-5ms, 30m, 0.32mm, 0.25µm (cat.# 13424)

Sample:

no sample injected; instrument ran the method conditions with no injection.

Inj.:

no injection; splitless mode (hold 0.5 min., split flow 40mL/min.)

4mm split with wool inlet liner, IP deactivated (cat.# 20782).

Inj. temp.:

250°C

Carrier gas:

helium, constant flow

Flow rate:

5.0mL/min.

Oven temp.:

50°C (hold 5 min.) to 320°C @ 30°C/min. (hold 10 min.)

Det.:

FID @ 330°C

GC_EX00957

Figure 3

Warmup your system and invest in quality liners to reduce noise and improve accuracy.

Column:

Rxi

®

-5ms, 30m, 0.32mm, 0.25µm (cat.# 13424)

Sample:

no sample injected; instrument ran the method conditions with no injection.

Inj.:

no injection; splitless mode (hold 0.5 min., split flow 40mL/min.)

4mm split with wool inlet liner, IP deactivated (cat.# 20782).

Restek

Competitor

First Run

Second Run

Third Run

GC_EX00954A

GC_EX00954B

GC_EX00954C

GC_EX00954D

GC_EX00954E

GC_EX00954F

First Run

Second Run

Third Run

Inj. temp.:

250°C

Carrier gas:

helium, constant flow

Flow rate:

5.0mL/min.

Oven temp.:

50°C (hold 5 min.) to 320°C @ 30°C/min. (hold 10 min.)

Det.:

FID @ 330°C

For a full listing of Restek liners, visit us at

www.restek.com400 pA

400 pA

30 pA

30 pA

30 pA

30 pA