• 20 •

2008 vol. 2

Using Thermal Desorption to Enhance

Aroma Profiling by GC/MS

Lower Detection Limits with Latest Technology

By Irene DeGraff, Product Marketing Manager, Lara Kelly, Markes International, and Liz Woolfenden, Markes International

Flavor and fragrance profiling by GC/MS presents significant analytical challenges, as profiles typically comprise hundreds of volatile

organic compounds (VOCs), often with the lowest concentration analytes having the most profound effects on perceived aroma.

Conventional sample preparation methods (solvent extraction, steam distillation, etc.) do not meet sensitivity requirements and

often distort the vapor profile so that it is not representative of what the consumer experiences. Recently, thermal desorption (TD)

has emerged as a useful complement to GC/MS, enabling more aroma profiling applications to be carried out using quantitative,

automatic instrumentation. TD combines automated sample preparation with selective analyte enrichment, allowing VOCs to be

injected into the GC/MS as a narrow concentrated band, free of most or all sample matrix effects.

Many Sampling Options, No Extraction Interferences

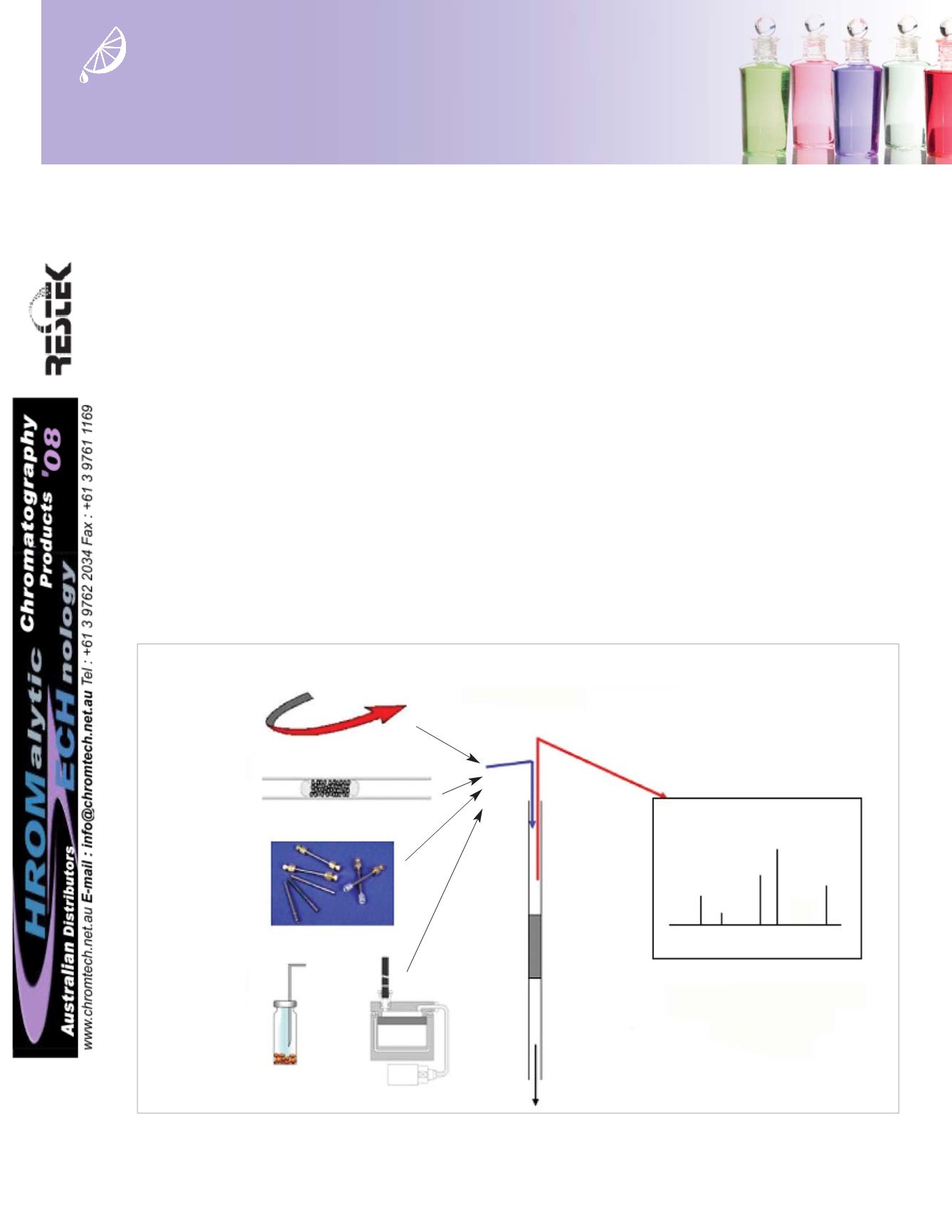

One of the strengths of thermal desorption for food, flavor, and fragrance profiling

is that it offers a versatile range of sampling methodologies including sorbent

tubes/traps, on-line sampling, direct desorption, and off-line thermal extraction

(dynamic headspace) sampling. Whichever of these approaches is used, the com-

pounds of interest are separated from the sample matrix and focused on a small, elec-

trically-cooled sorbent trap (Figure 1). This focusing trap is subsequently desorbed

by heating it rapidly in a reverse flow of carrier gas causing the VOCs to be injected

into the GC/MS system as a narrow band of vapor. Since samples are extracted directly

• Accommodates a wide range of sampling methods.

• Allows sample re-collection, for repeat analysis and result verification.

• Eliminates extraction solvents, purges volatile interferences, and concentrates sample vapors, for enhanced

low-level detection.

Figure 1

Thermal desorption is compatible with a wide range of sampling strategies.

On-line air/

gas sampling

Direct desorption

of materials

100-200μL injection

of vapor into GC/MS

Vapors sampled

onto sorbent tubes

Headspace-trap

or thermal

Thermal desorption is an

automatic, high-sensitivity

alternative to conventional

liquid extraction.

Food, Flavors & Fragrances