• 8 •

2008 vol. 3

Environmental

While PTV is popular internationally, it is an emerging technique in US laboratories and is expected to grow with the awareness of

this versatile technique. Now, using a PTV On-Column liner, the capabilities of PTV can be expanded to include true on-column

injections, which normally would have required a separate injection port. Why incur the additional expense of a separate injection

port when the same results can be achieved with a simple liner change? Restek’s PTV On-Column liner, available for Agilent PTVs

and the Gerstel CIS4, allows you to perform true cold on-column injections with a PTV port, saving you money and retaining the

versatility of the PTV inlet

A Simple Solution

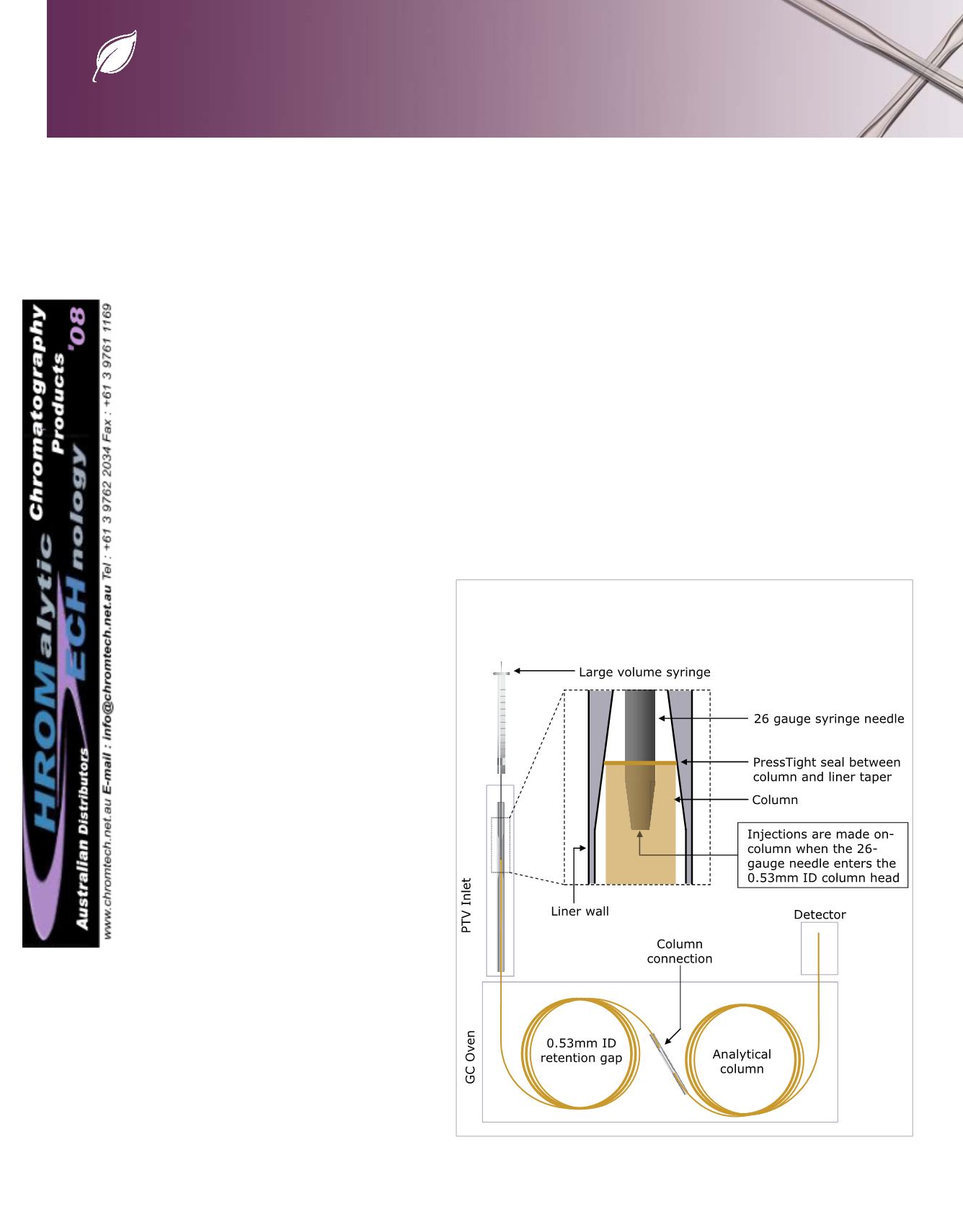

Figure 1 illustrates how this liner works. A 0.53mm ID retention gap column is pressed into the bottom restriction of the liner, form-

ing a leak-free seal between the retention gap’s polyimide coating and the inner wall of the liner. The liner’s top restriction guides a

26-gauge needle down into the 0.53mm ID retention gap, allowing samples to be injected directly on-column.

Protect Sensitive Compounds

By operating the inlet at low temperatures, an ini-

tial flash vaporization is eliminated, protecting

thermally labile compounds. Injecting the sample

directly into the column also helps avoid injection

port activity issues and increases transfer of lower

volatility compounds. Both of these features help

decrease sample degradation, increase sensitivity,

and improve reproducibility. Figure 2 illustrates

the outstanding reproducibility that can be

achieved with this liner using an example of explo-

sives as probes. Absolute standard deviations were

just 2.6% (500pg/µL nitroglycerin) and 1.5%

(100pg/µL TNT) for relative peak areas over 5

replicate injections. Variation in realative area was

similarly low for both compounds.

Increase Injection Volume

An additional advantage of this liner configuration

is the increased analytical sensitivity that can be

obtained by injecting a larger sample volume.

When the sample needs to be flash vaporized, sam-

ple volume expansion in the liner quickly becomes

a concern, limiting injection volume to 1-2µL of

sample. However, with cold on-column injections,

larger sample volumes can be used because the sol-

vent can be gradually vaporized and eluted before

the analytes. Using a larger sample volume means

more analyte is loaded on-column, giving greater

overall sensitivity. The data in Figure 3 demon-

strate the excellent linearity achievable using the

PTV On-Column liner across a range of injection

volumes. Instead of a traditional calibration curve

that plots response vs. increasingly concentrated

standards, this plot illustrates response vs. increas-

ing volumes of the same standard, in effect pro-

ducing the same result of more mass on-column.

The correlation between peak area and injection

volume (5 -100µL) was evaluated and r

2

values of

Figure 1

Use a PTV On-Column liner to perform cold on-column

column injections in a PTV injection port.

PTV On-Column Liner Gives You Two Inlets in One

Why pay for a separate injection port when a simple liner change can convert your programmable tem-

perature vaporization (PTV) inlet to allow for true cold on-column injections? Save time andmoney by

using Restek’s

PTVOn-Column Liner

.

By Scott Grossman, Innovations Chemist, Jack Cochran, Director of New Business and Technology, and Jaap de Zeeuw, International GC Specialist

Using the PTV On-Column liner decreases

sample degradation, increases sensitivity,

and improves reproducibility.

Turn one inlet into

two—with a simple

liner change!

800-356-1688 •

www.restek.com