• 13 •

www.restekcorp.comPlus 1

™

means that we will surpass your expec-

tations every time you contact us. Looking for

the solution to your tough analytical problem or

placing a late-day order? Contact us to

experience Plus 1

™

service today!

Articles on pages 4 and 7 of this

Advantage

describe analyses of phenols and active semivolatile

organic compounds that are notoriously difficult to

analyze, particularly at low concentrations. Low-

level injections reduce sensitivity for these com-

pounds, due to degradation or irreversible adsorp-

tion in the injection port. Residues of heavier and

non-volatile materials often build up at the bottom

of the injection port, leaving a reactive surface that

can cause active compounds to break down.

To circumvent this problem, we use a deactivated,

Drilled Uniliner

®

inlet liner (Figure 1) in the inlet,

in place of a standard splitless inlet liner, to mini-

mize sample exposure to the hot metal surfaces of

the injection port. A Drilled Uniliner

®

liner makes a

press-fit connection between column and liner,

eliminating the primary source of analyte break-

down. This physical connection between column

and liner also improves sensitivity, by minimizing

injection port discrimination. Further, with a Drilled

Uniliner

®

inlet liner less of the injected sample is

vented, should you need to switch from splitless to

split mode to sweep remaining solvent from the

inlet. This too contributes to greater sensitivity.

We tested the performance of a system that included

a Drilled Uniliner

®

inlet liner, using a mixture of

chlorinated pesticides at 20, 40, and 200ng/mL con-

centrations (

Restek Advantage

2002v4). The per-

cent difference between the observed value and the

"true" value for each analyte ranged from 0% to a

maximum of only 6.4%. The system that included the

Drilled Uniliner

®

inlet liner reduced endrin and DDT

breakdown, relative to systems that included splitless

liners (Table 1), because a splitless liner allows the

analytes to contact active surfaces in the inlet. Wool

packing in the splitless liner aggravates this problem,

by greatly increasing the surface area within the liner

and introducing additional active sites.

In addition to reducing variability and increasing

accuracy of calibration data, a Drilled Uniliner

®

inlet liner increased overall response for individual

analytes, enhancing minimum detection levels com-

pared to standard splitless inlet liners. In the pesti-

cides test, area counts for the last eluting peak,

decachlorobiphenyl, were greater by 18-39% when

a Drilled Uniliner

®

inlet liner was used, relative to

area counts for injections made on splitless liners

(Table 1).

By eliminating the bottom of the injector from the

sample pathway, a Drilled Uniliner

®

inlet liner

makes the pathway more inert. This can increase

accuracy and precision, and reduce breakdown of

active analytes, relative to hot flash injection tech-

niques. If you are conducting analyses of phenols,

chlorinated pesticides, or other active analytes,

these results clearly show that a Drilled Uniliner

®

inlet liner could be the liner of choice.

by Gary Stidsen and Lydia Nolan, Innovations Team

Improved Responses for Active

Analytes

Using a Drilled Uniliner

®

GC Inlet Liner

✔

Less breakdown of active compounds, for more accurate results.

✔

Greater sensitivity, for lower detection limits.

✔

Minimal injection port discrimination.

DI Liners for Agilent 5890 & 6890 GCs

(For 0.25/0.32/0.53mm ID Columns)

ID*/OD &

Length (mm)

cat.#/price

ea.

cat.#/price

5-pk.

Drilled Uniliner

®

4.0 ID

6.3 OD x 78.5

21054

21055

Siltek

™

Drilled Uniliner

®

4.0 ID

6.3 OD x 78.5

21054-214.1 21055-214.5

Siltek

™

1mm Drilled Uniliner

®

1.0 ID

6.3 OD x 78.5

21390-214.1 21391-214.5

Hole makes

direct injection

possible with

EPC-equipped

Agilent 6890

GCs!

% Breakdown

Drilled

4mm splitless

4mm splitless

Analyte

Column

Uniliner

®

with wool

Endrin

Rtx

®

-CLPesticides

4.4

4.7

9.8

Rtx

®

-CLPesticides2

4.9

6.9

8.3

DDT

Rtx

®

-CLPesticides

0.2

0.3

2.6

Rtx

®

-CLPesticides2

0.3

0.9

3.1

Response—

Mean response; value in table x 10

3

= response units.

Drilled

4mm splitless

4mm splitless

Analyte

Column

Uniliner

®

with wool

Tetrachloro-

m

-

Rtx

®

-CLPesticides

147

111

106

xylene (TCMX)

Rtx

®

-CLPesticides2

191

167

162

Decachloro-

Rtx

®

-CLPesticides

150

119

108

biphenyl (DCB) Rtx

®

-CLPesticides2

209

177

166

Table I

Lowest breakdown of endrin and DDT, and highest responses for analytes, using a Drilled

Uniliner

®

inlet liner.

*Nominal ID at syringe needle expulsion point.

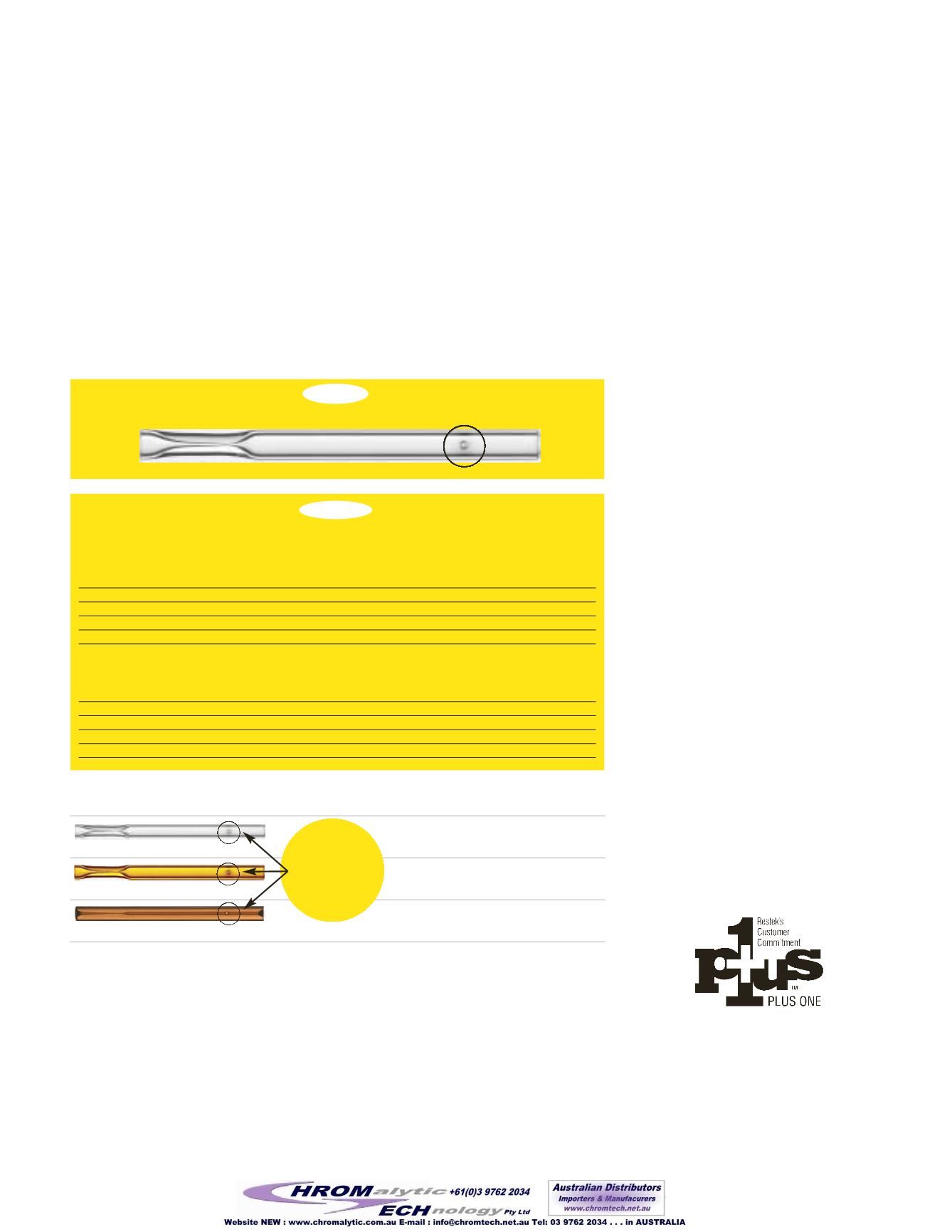

Figure 1

Reduce the loss of active analytes—use a Drilled Uniliner

®

inlet liner.

Visit us at Pittcon

®

2003!

Booth #6151

See our website for more information about

• Technical presentations

• Workshops