• 10 •

www.restekcorp.com800-356-1688

by Rebecca E. Wittrig, Ph.D., Food, Flavor, and Fragrance Innovation Team Leader;

and Kevin MacNamara, Ph.D., Irish Distillers Ltd.*

GC Analysis of Acids, Esters,

and Other Flavor Components in

Distilled Liquor Products

Stabilwax

®

-DA GC Column—Part I

✔

High thermal stability (250°C) and solvent rinsibility result in long

column lifetime.

✔

Optimized configuration reduces analysis time by 4-fold.

✔

Low bleed for accurate quantitation.

Part I: The Separation

Distilled liquor products contain a wide range of

volatile and non-volatile compounds in an

ethanol/water matrix. The most abundant fusel

alcohols and esters can be determined by gas chro-

matography (GC) with a simple split injection,

which also minimizes the amount of matrix ethanol

and water transferred to the column. However,

many additional trace fatty acids and their esters—

often used to indicate quality of alcoholic beverages

such as whiskey and rum—cannot be determined

by this approach. Because the concentrations can

vary widely, splitless injection techniques with some

type of preconcentration step usually are necessary

to analyze fatty acids, esters, and other flavor com-

pounds.

Large ranges of volatility and acidity for the compo-

nent list make quantitating them in a single separa-

tion difficult to accomplish. The Stabilwax

®

-DA col-

umn, a bonded polyethylene glycol (PEG) phase, is

excellent for analyzing alcoholic beverage samples

(Figure 1). Using this column, flavor compounds in

distilled liquor products can be quantitated in a

single splitless injection. An optimized configuration

of 30m, 0.18mm ID, 0.18µm allows significantly

reduced analysis times. To improve the peak shape

and reproducibility of acidic components in these

samples, an acidic functionality has been added to

the backbone of the PEG stationary phase. This

results in less adsorption of free fatty acids and,

thus, significantly less peak tailing. Also, because of

the inertness of this stationary phase towards acidic

components present in the sample, greater repro-

ducibility and longer column lifetimes are possible.

One of the critical pairs in the GC analysis of esters

and acids in distilled liquor products is caproic

acid and ethyl laurate. These components can be

difficult to resolve on standard Carbowax

®

-type

columns. This is especially true if peak tailing or

broadening occurs, or if one component is present

at a significantly higher concentration. The

Stabilwax

®

-DA column achieves baseline resolution

of these two compounds within a reasonable analy-

sis time of 30 minutes (Figure 2).

*Irish Distillers Ltd., Bow Street Distillery, Smithfield, Dublin 7, Ireland

Part II

of this article will appear in the

Winter '01/’02 Advantage. We will look at

the Stabilwax

®

-DA column for alcoholic

beverage analysis. Trace-level components,

such as the ones displayed in Figure 1,

often can be used to "fingerprint" a particu-

lar type or brand of distilled liquor. The

application of this methodology to whiskey

products will be discussed in Part II.

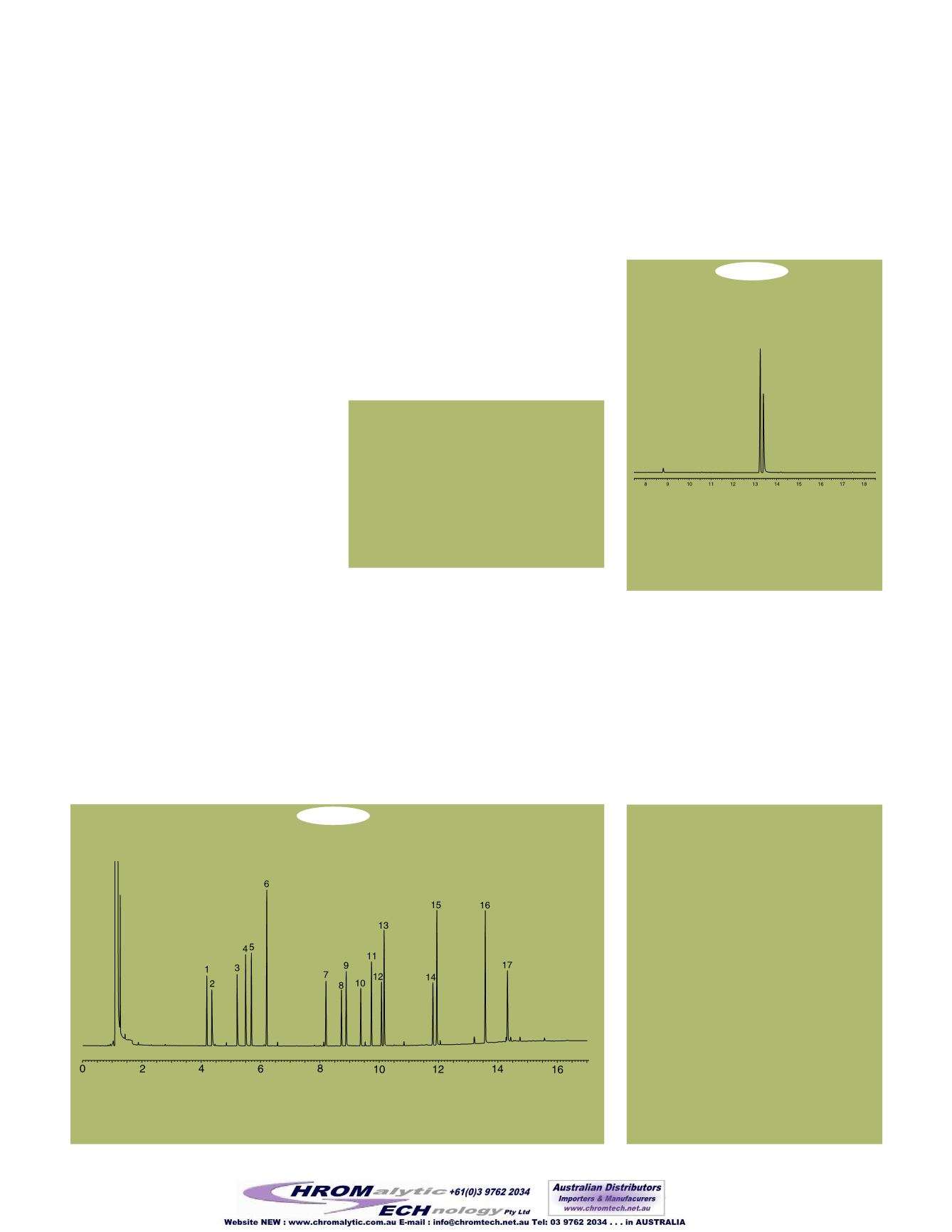

Peak List for Figures 1 & 3

compound

conc. (ppm)

1. ethyl octanoate

100

2. acetic acid

100

3. propionic acid

100

4. isobutyric acid

100

5. decanol 3

50

6. ethyl decanoate

50

7. ethyl laurate

50

8.

cis

-lactone

100

9. 2-phenylethanol

50

10.

trans

-lactone

100

11. methyl myristate

50

12. ethyl myristate

50

13. octanoic acid

100

14. ethyl palmitate

50

15. decanoic acid

100

16. dodecanoic acid

100

17. vanillin

100

Figure 1

The Stabilwax

®

-DA column provides excellent peak shape of free fatty acids, esters, and

other flavor compounds contained in an alcoholic beverage test mix.

30m, 0.18mm ID, 0.18µm Stabilwax

®

-DA (cat.# 550752)

Oven temp.:

70 to 240°C at 12°C/min. (hold 3 min.);

GC:

ThermoQuest Trace 2000;

Inj.:

1µL splitless at conc. shown

in peak list, in ethyl acetate;

Detector:

FID;

Inj. & det. temp.:

240°C;

Liner:

4mm ID splitless liner w/wool (cat.#

20814-202.1);

Hold time:

0.5 min.;

Carrier gas:

hydrogen;

Make-up gas:

nitrogen;

Linear velocity:

28psi @ 240°C

Figure 2

The Stabilwax

®

-DA column achieves

complete resolution of caproic acid and

ethyl laurate in 30 minutes.

30m, 0.18mm ID, 0.18µm Stabilwax

®

-DA (cat.# 550752)

Oven temp.:

80 to 230°C at 5°C/min.;

See Figure 1 for complete conditions.

1. caproic acid

100 ppm

2. ethyl laurate

100 ppm

Because alcoholic beverage samples often are

injected via splitless mode, the stability of the

Stabilwax

®

-DA column when exposed to aqueous

injections is important. We verified stability by per-

forming a splitless injection of the alcoholic bever-

age test mix, followed by five 1µL injections of

water. This process was repeated 10 times, followed

by a final injection of the test mix. The final test mix

injection can be seen in Figure 3. Even after repeat-

ed splitless injections of 100% water, very little

degradation occurs in the peak shapes of the test

min.

GC_FF00500

GC_FF00525

1

2