• 8 •

www.restekcorp.com800-356-1688

Many laboratories performing gas chromatography

(GC) analysis of chlorinated pesticides struggle with

endrin breakdown caused by the compound adsorb-

ing to active sites throughout the analytical system,

especially in the injection port and the analytical

column. Restek Siltek

™

technology—used success-

fully to passivate injection port liners and guard

columns—is now available in Stx

™

-CLPesticides and

Stx

™

-CLPesticides2 capillary columns. The combina-

tion of a properly deactivated injection system and

inert analytical columns provides the lowest possible

level of endrin breakdown.

Method Requirements

Chlorinated pesticide analyses following US

Environmental Protection Agency (EPA) Methods

8081, 608, 505 and 508 recommend dual-column

confirmation using electron capture detection

(ECD). The most common analytes of interest are

analyzed in Figure 1. As in all analytical methods,

the instrument used for quantitative analysis must

be calibrated to ensure accurate results are report-

ed. For chlorinated pesticides this usually entails a

calibration curve of three to five points and check

standards injected at specified time intervals during

sample analysis. In addition, performance stan-

dards containing endrin are analyzed periodically

to ensure system inertness. Typically, endrin breaks

down to endrin aldehyde and endrin ketone when

there are active sites in the sample pathway, and

their presence must also be verified.

Endrin Breakdown

Maintaining a low breakdown level for endrin is

necessary for laboratories analyzing chlorinated pes-

ticides. Reduction of endrin breakdown generally

focuses on improving the inertness of the injection

port (see sidebar on page 9). Recently, liners treat-

ed with Siltek

™

deactivation were designed to pre-

vent endrin breakdown in the injection port. This

innovative deactivation technology also was incorpo-

rated into capillary guard tubing so that the entire

sample introduction pathway is as inert as possible.

by Lydia Nolan, Environmental Innovations Chemist, and

Gary Stidsen, Innovations Team Manager

Reduced Endrin Breakdown

for Chlorinated Pesticides

Analysis

Stx

™

-CLPesticides GC Column Pairs

✔

Siltek

™

-deactivated analytical columns decrease endrin breakdown.

✔

Same selectivity as Rtx

®

-CLPesticides column pairs—no modification

to analysis parameters.

✔

Flow adjustments improve separation.

Endrin Response

In addition to breakdown, endrin response can be

reduced by irreversable adsorption onto active sites

in the sample pathway. To minimize on-column

adsorption of endrin, we incorporated Siltek

™

deactivation technology into the analytical columns.

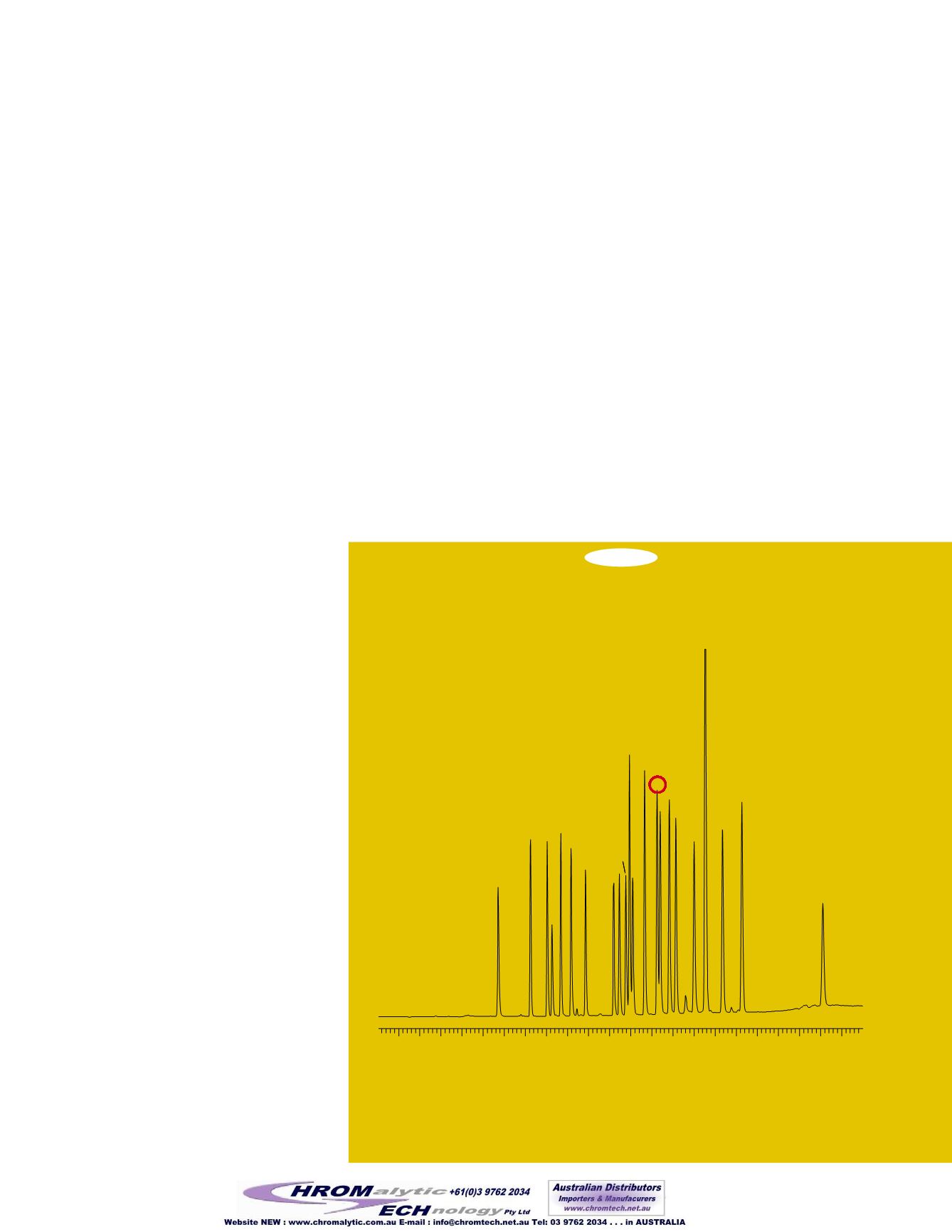

Figure 1

Highly inert Stx

™

-CLPesticides and Stx

™

-CLPesticides2 columns provide excellent response for

active pesticides such as endrin, DDT, and methoxychlor so you get accurate quantitation.

Combining Siltek

™

deactivation with the unique

selectivity of Restek CLPesticides phases results in

the new Stx

™

-CLPesticides and Stx

™

-CLPesticides2

columns, and a significant improvement in endrin

response compared to “Rtx” columns (Figure 1).

Using the Stx

™

-CLPesticides and Stx

™

-CLPesticides2

columns, the endrin peak response is now higher

than the analytes eluting in the same region—

something not seen consistently in columns using

traditional deactivations.

Column Installation and Optimizing

Resolution

The Stx

™

-CLPesticides2 column is the ideal confirma-

tional column to the Stx

™

-CLPesticides column. It

was designed to achieve resolution of the chlorinated

pesticides using the same flowrate and oven temper-

ature program. The columns can be installed in par-

allel using a universal Siltek

™

Press-Tight

®

“Y” con-

nector or a metal MXT

®

“Y” connector. This parallel

set-up reduces downtime caused by maintenance of

multiple injection ports. Additionally, these columns

can be installed in separate injection ports and

mounted in the same GC oven.

GC_EV00512

Oven temp.:

110°C (hold 1 min.) to 245°C @ 20°C/min. to 300°C @ 6°C/min.;

Inj. & det. temp.:

210°C / 310°C;

Carrier gas:

helium;

Dead time:

0.8min. @ 120°C;

Inlet liner:

Siltek

™

Uniliner

®

w/hole (cat.# 21055-214.5);

Inj.:

1µL direct injection of

20/40/200ng/mL std. concentration in hexane;

Make-up gas:

nitrogen

3

4

5

6

7

8

9

10

11

12

13

1

2 3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Stx

™

-CLPesticides

30m, 0.32mm ID, 0.5µm

(cat.# 11544)