• 10 •

www.restekcorp.com800-356-1688

Swagelok

®

fittings are world-renowned for meeting

demanding standards. Now, Restek is pleased to set

the new standard for inert or corrosion-resistant

tubing system components: Swagelok

®

products with

Restek's unparalleled surface treatments—Siltek

™

or Silcosteel

®

-CR treatment—available from stock.

Siltek

™

treatment, which is equivalent to Sulfinert

®

treatment, is the ideal choice for ultimate inertness,

intended specifically for systems used to collect,

store, and transfer active compounds. The most

reactive sample components can be stored and

transferred via a Siltek

™

treated system: even at

parts-per-billion levels, sulfur-containing or other

very active compounds exhibit virtually no adsorp-

tion. And, unlike coatings, Siltek

™

and other Restek

treatments produce a layer that is integral with the

fitting surface—it will not chip, flake, or delaminate,

even in the most stressful applications.

Silcosteel

®

-CR treatment is highly effective protection

for stainless steel exposed to hydrochloric, nitric, or

sulfuric acid, or to marine environments. In inde-

pendent tests, Silcosteel

®

-CR treatment upgraded the

corrosion resistance of 300-grade stainless steel

samples by an order of magnitude (Table 1) and

totally protected them against crevice corrosion

(Figure 1).

Inert, High-Quality Fittings

and Tubing for

Demanding Applications

by Gary Barone, Restek Performance Coatings Division

Siltek™/Sulfinert® and Silcosteel®-CR Treated Swagelok® Fittings

✔

Siltek

™

/Sulfinert

®

treatment* ensures ultimate inertness.

✔

Silcosteel

®

-CR treatment enhances acid resistance tenfold, or more.

✔

Restek treatments cannot chip, flake, or delaminate.

✔

Custom treatment available.

Fitting Type

Similar to

Siltek

™

/Sulfinert

®

Silcosteel

®

-CR

Size

Swagelok

®

# qty.

cat.# price qty.

cat.# price

Union

1

/

16

"

SS-100-6

ea.

22540

ea.

22575

1

/

8

"

SS-200-6

ea.

22541

ea.

22576

1

/

4

"

SS-400-6

ea.

22542

ea.

22577

Tee

1

/

16

"

SS-100-3

ea.

22543

ea.

22578

1

/

8

"

SS-200-3

ea.

22544

ea.

22579

1

/

4

"

SS-400-3

ea.

22545

ea.

22580

Reducing Union

1

/

8

" to

1

/

16

"

SS-200-6-1

ea.

22546

ea.

22581

1

/

4

" to

1

/

16

"

SS-400-6-1

ea.

22547

ea.

22582

1

/

4

" to

1

/

8

"

SS-400-6-2

ea.

22548

ea.

22583

Union Elbow

1

/

8

"

SS-200-9

ea.

22549

ea.

22584

1

/

4

"

SS-400-9

ea.

22550

ea.

22585

Plug

1

/

16

"

SS-100-P

ea.

22572

ea.

22619

1

/

8

"

SS-200-P

ea.

22573

ea.

22620

1

/

4

"

SS-400-P

ea.

22574

ea.

22597

Cross

1

/

8

"

SS-200-4

ea.

22551

ea.

22586

1

/

4

"

SS-400-4

ea.

22552

ea.

22587

Tube End Reducer

1

/

8

" tube to

1

/

16

"

SS-100-R-2

ea.

22553

ea.

22588

1

/

4

" tube to

1

/

16

"

SS-100-R-4

ea.

22554

ea.

22589

1

/

8

" tube to

1

/

4

"

SS-400-R-2

ea.

22555

ea.

22590

1

/

4

" tube to

1

/

8

"

SS-200-R-4

ea.

22556

ea.

22591

Port Connector

1

/

8

"

SS-201-PC

ea.

22557

ea.

22592

1

/

4

"

SS-401-PC

ea.

22558

ea.

22593

1

/

8

" tube to

1

/

4

"

SS-401-PC-2

ea.

22559

ea.

22594

Male Connector

1

/

8

" to

1

/

8

" NPT

SS-200-1-2

ea.

22561

ea.

22595

1

/

4

" to

1

/

4

" NPT

SS-400-1-4

ea.

22562

ea.

22596

1

/

16

" to

1

/

8

" NPT

SS-100-1-2

ea.

22563

ea.

22610

1

/

8

" to

1

/

4

" NPT

SS-200-1-4

ea.

22564

ea.

22611

1

/

4

" to

1

/

8

" NPT

SS-400-1-2

ea.

22565

ea.

22612

Female Connector

1

/

8

" to

1

/

8

" NPT

SS-200-7-2

ea.

22566

ea.

22613

1

/

4

" to

1

/

4

" NPT

SS-400-7-4

ea.

22567

ea.

22614

1

/

4

" to

1

/

8

" NPT

SS-400-7-2

ea.

22568

ea.

22615

1

/

8

" to

1

/

4

" NPT

SS-200-7-4

ea.

22569

ea.

22616

Bulkhead Union

1

/

8

"

SS-200-61

ea.

22570

ea.

22617

1

/

4

"

SS-400-61

ea.

22571

ea.

22618

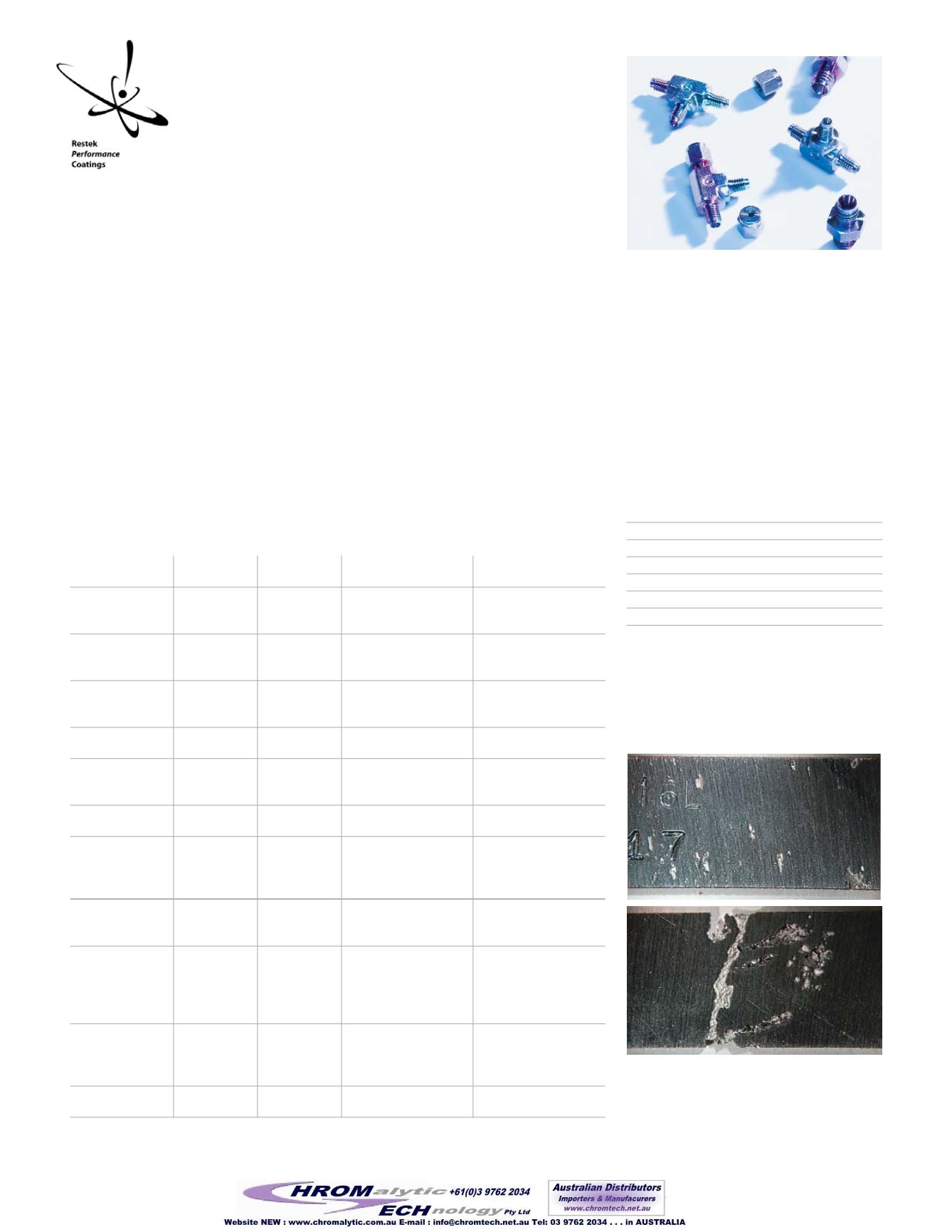

Figure 1

Silcosteel®-CR treated 316L stainless

steel coupons show no crevice corrosion and

only slight pitting corrosion (top), while bare

316L stainless steel coupons exhibit severe

crevice corrosion (bottom).

Table 1

Silcosteel®-CR treated stainless steel

coupons show little weight loss after exposure to

6% w/w ferric chloride solution.

Sample

Weight Loss (g/m

2

)

Silcosteel

®

-CR 17

19

Silcosteel

®

-CR 28

25

Silcosteel

®

-CR 47

25

Bare Steel 27

231

Bare Steel 34

209

Bare Steel 37

228

If you need to construct a system for a demanding

application, you will not find more suitable fittings

than Restek treated Swagelok

®

fittings. Siltek

™

,

Silcosteel

®

-CR, or other Restek surface treatments

can be applied to other fittings or parts on

request—contact our Technical Service chemists or

your Restek representative.