RestekCapillaryColumn InstallationGuide, Section II

length (m)

hydrogen

helium

15

0.63min./TCD

1.25min.

30

1.25min.

2.5min.

60

2.5min.

5.0min.

105

4.38min.

8.75min.

* Nitrogen is not recommended as a carrier gas for most capillary columns because inadequate resolution and longer

analysis times result.

IV. Confirming Installation Integrity

We highly recommend using the dead volume peak shape test and the solvent peak

shape test to confirm installation integrity.

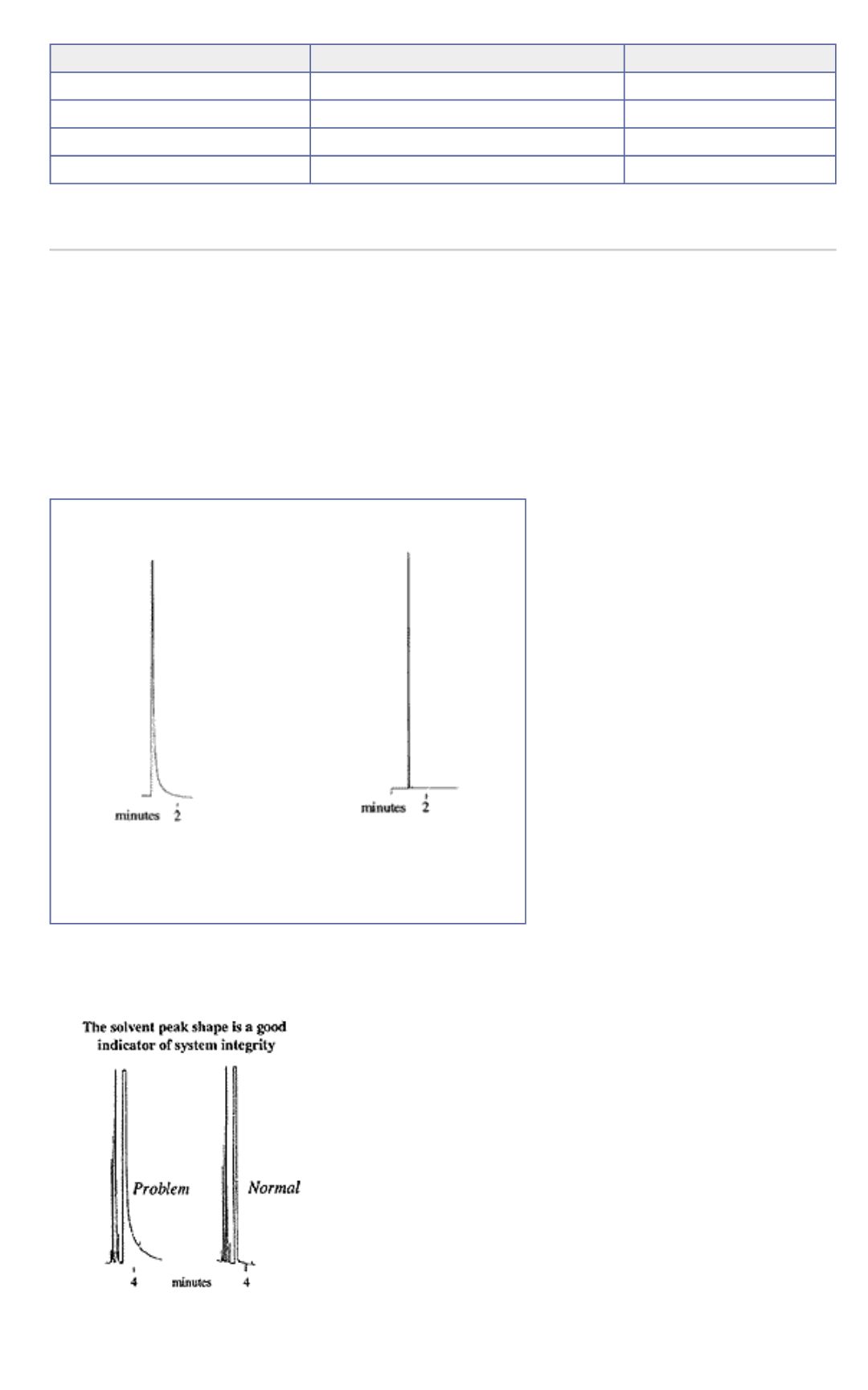

DeadVolumePeakShape Test

Examine the dead volume peak. A sharp, narrow peak that shows no sign of tailing

indicates an unobstructed sample pathway and correct installation (

FigureH

). Tailing

peaks indicate improper column installation, gross contamination of the splitter sleeve,

a cracked splitter sleeve, improper sweeping of the column end bymake-up gas, a

crushed column end, or a column that has degraded. The cause of a tailing non-retained

peakmust be corrected before using the column analytically.

FigureH

: Dead volume peak shape test

Tailing peaks indicate

improper installation

Symmetrical Peaks

indicate

proper installation

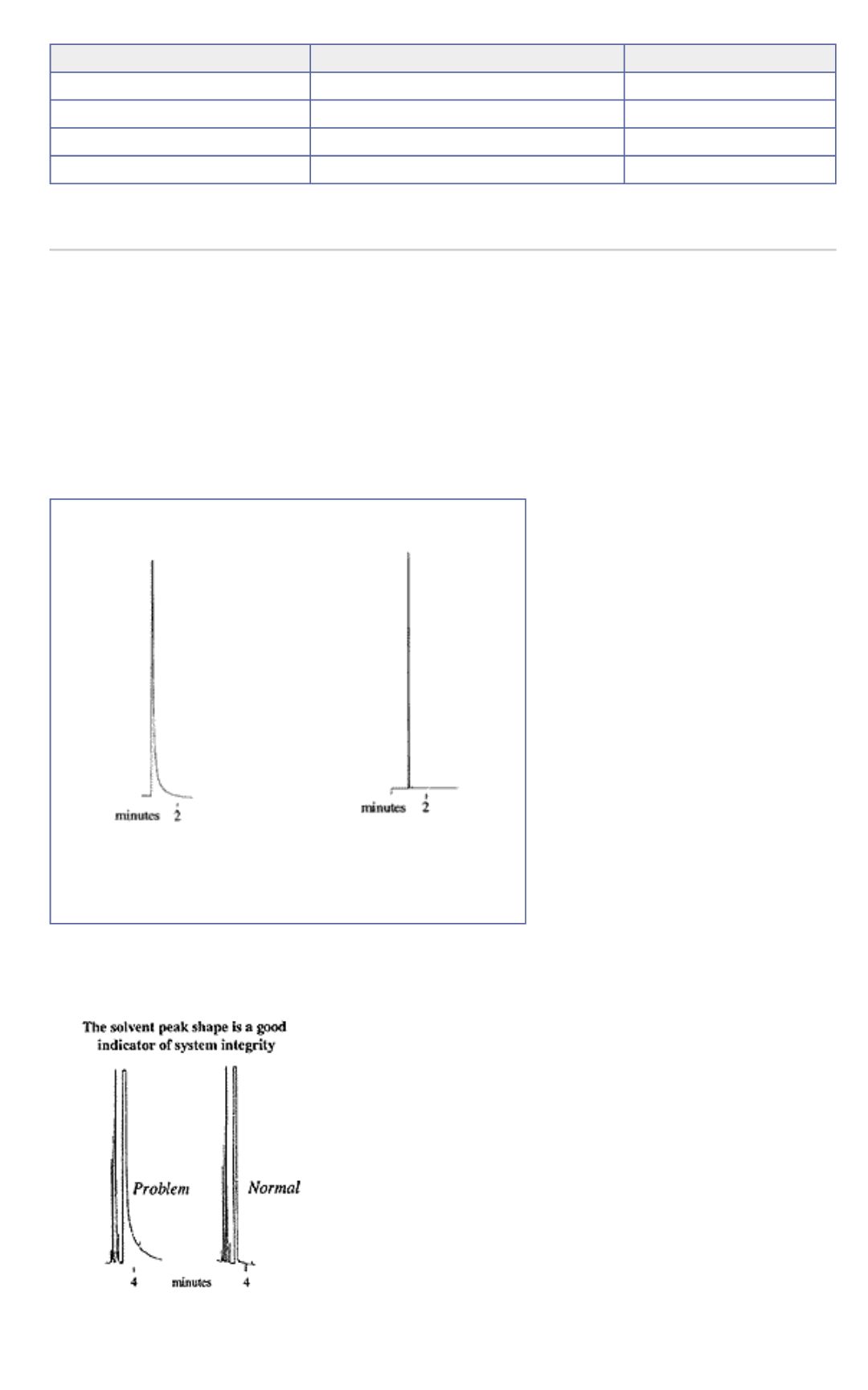

Solvent PeakShape Test

The solvent peak shape test is an additional indicator of proper column installation in

the inlet and outlet. Since compounds used to set the dead volume are usually gases at

room temperature (methane), they are not extremely

sensitive indicators of system or installation problems.

A 1µl injection of a liquid solvent, such asmethylene

chloride, expands to over 500µl of gas volume, making

any potential installation or system problem readily

apparent. A tailing solvent peak is a sensitive indicator

of broken, undeactivated, or contaminated inlet

sleeves. Tailing solvents also indicate problems with

inadequatemake-up gas or improper column insertion

into the detector.

To perform the test, inject 1µl of a solvent in the split

mode at 40°C isothermal and examine the peak shape

(

Figure I

). The solvent peak should be symmetrical

and showminimal tailing. If tailing appears, suspect an

installation or system problem. The cause of a tailing