RestekCapillaryColumn InstallationGuide, Section II

Nominal

Tubing ID

Nominal TubingOD

MXT

FusedSilica

0.05mm

---

---

0.363mm +/-0.012mm

0.10mm 0.23mm +/-

0.0254mm 0.363mm +/-0.012mm

0.15mm 0.41mm +/-

0.0254mm 0.363mm +/-0.012mm

0.18mm 0.36mm +/-

0.0254mm 0.34mm +/-0.01mm

0.25mm 0.41mm +/-

0.0254mm 0.37mm +/-0.04mm

0.28mm 0.56mm +/-

0.0254mm

---

---

0.32mm 0.41mm +/-

0.0254mm 0.45mm +/-0.04mm

0.53mm 0.74mm +/-

0.0254mm 0.69mm +/-0.05mm

0.75mm 0.93mm +/-

0.0254mm

---

---

InstallationPreparation

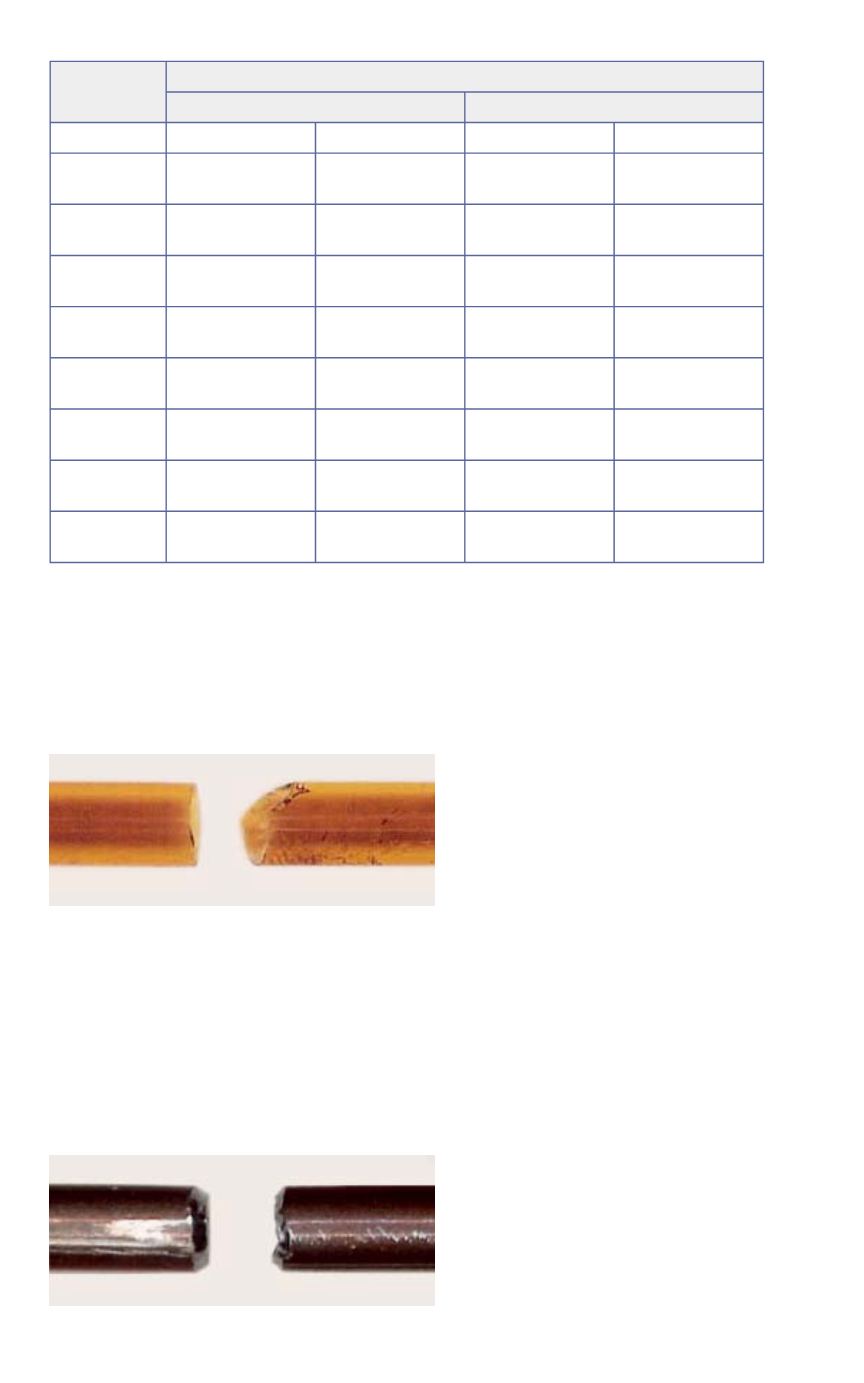

Cut each column end squarely, approximately 10 centimeters from the end seals. To

obtain a square cut with fused silica columns, place the column end against the

forefinger and score the polyimide layer lightly and rapidlywith a sapphire scribe (cat.#

20115) or a ceramic scoringwafer (cat.# 20116). Score only one side of the column.

Point the column end down to prevent polyimide or fused silica shards from falling

inside, and quickly flick the column just above the score.

Proper and improper fused silica cuts.

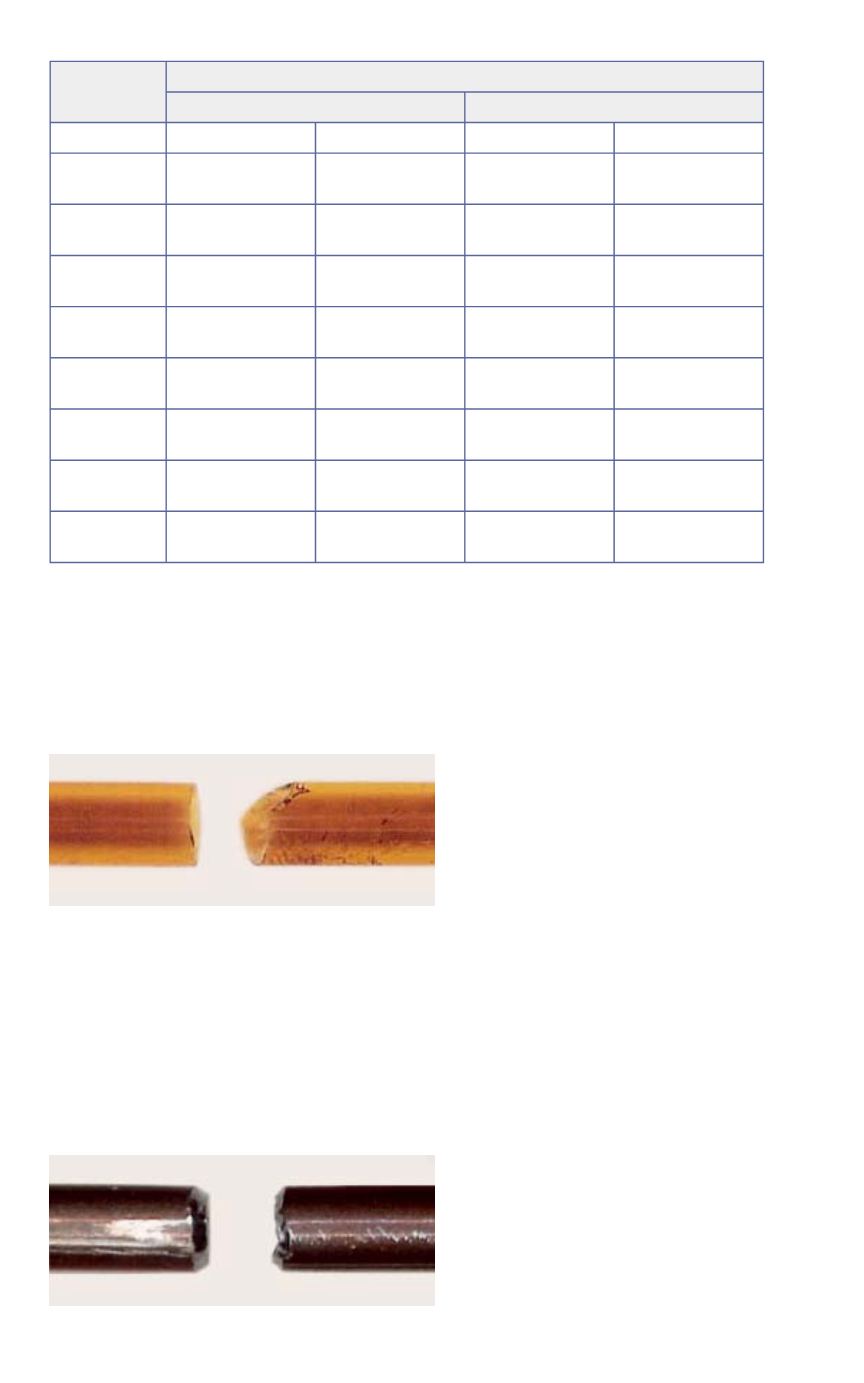

Cut metal capillary tubing by scoring the tubingwall (without cutting completely

through) with the edge of a sharp file or ceramic scoringwafer. Wipe any filings off the

tubing and bend it away from the score. Once the score opens, bend the tubing in the

opposite direction (toward the score) until it snaps into two pieces. If the hole is not

round or there is a burr on the tubing, try the procedure again. The flat side of a

ceramic scoringwafer can be used to polish or round the column end into a smooth

conical shape. We do not recommend using high speedwheels or grinders to cut the

metal tubing since theymay introducemetal filings into the tubing or ruin the polymer

near the cut from the high temperatures created.

Proper and improper MXT® column cuts.