RestekCapillaryColumn InstallationGuide, Section II

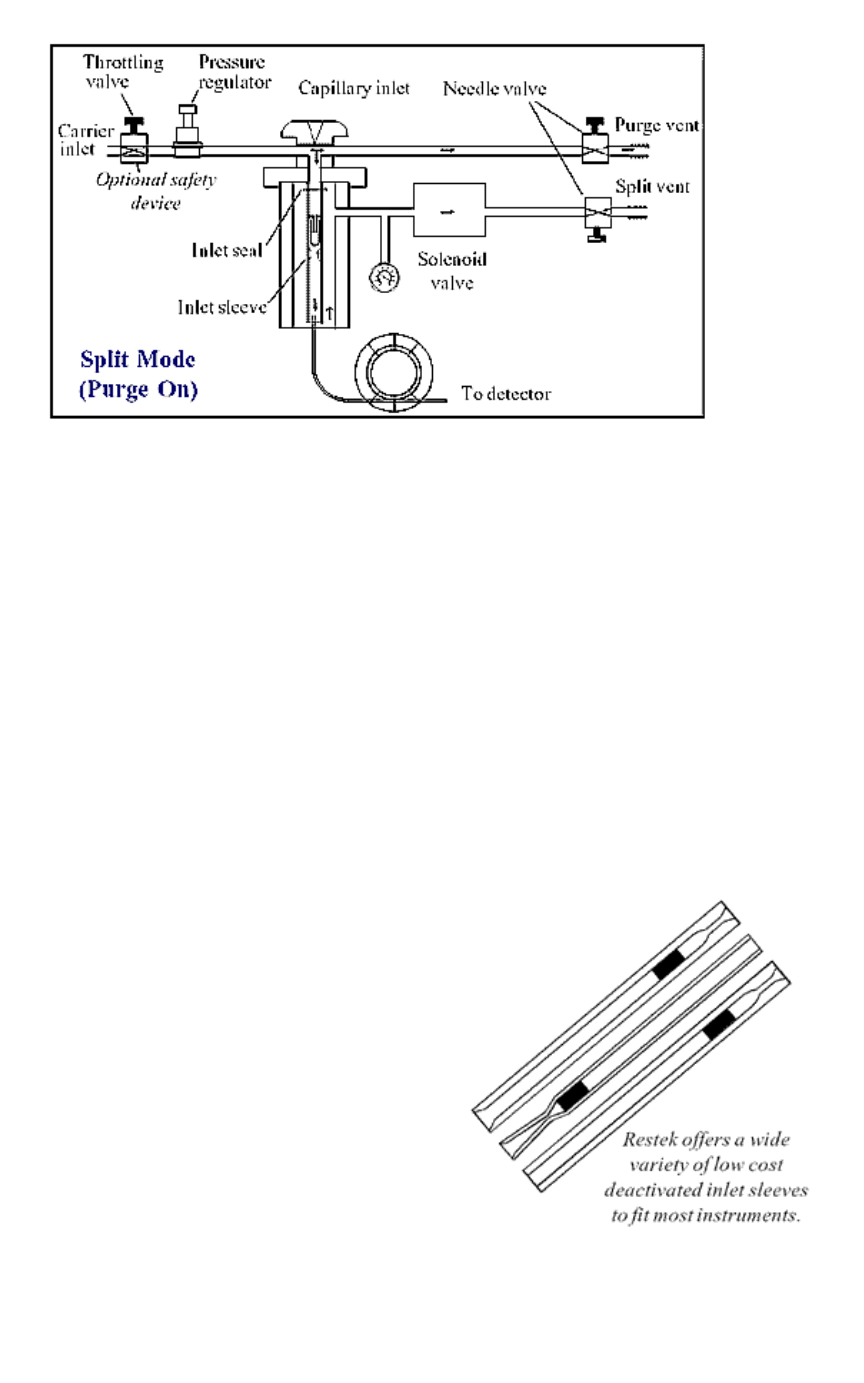

We recommend placing a throttling valve (needle valve or restrictor) on the carrier gas

inlet bulkhead fitting of pressure-regulated systems to prevent a catastrophic carrier

gas loss should an inlet leak occur. If several GCs are attached to a common carrier gas

source, a leak in one GC could drain the carrier gas from all other GCs, causing a loss of

flow and subsequent damage to all capillary columns in the entire system. To prevent

this from happening, limit the flow of carrier gas to each gas chromatograph (via a

throttling valve) until it matches the flow requirements of the inlet system. This can be

detectedwhen the column's head pressure starts to decrease if the throttling valve is

closed any further.

InjectorMaintenance

Perform injector maintenance prior to installing a capillary column. Periodic

maintenance is required after installation, depending on the number of injections and

the cleanliness of the samples. Maintenance includes cleaning and deactivating inlet

sleeves, replacing critical inlet seals, and replacing the septum. Review the instrument

manual inlet diagram prior to disassembly.

Cleaning andDeactivating Injector Sleeves

Don't install a new Restek columnwith a dirty injector sleeve! For optimum column

performance, the inlet sleeve needs to be free of septum particles, sample residue, and

ferrule fragments. Use deactivated inlet sleeves when analyzing samples with active

functional groups or compounds prone to decomposition or adsorption onto untreated

glass surfaces.

If the sleeve is deactivated and not

excessively dirty, cleaningwith organic

solvents will not affect the integrity of the

deactivation layer. First, use non-swelling

organic solvents such asmethanol or

isopropyl alcohol to remove septum

particles that adhere to the sleevewall.

Next, use solvents such as pentane,

methylene chloride, or toluene to remove

sample residue. Nylon tube brushes and

pipe cleaners (cat.# 20108) are ideal for

cleaning sleeves. Do not use laboratory

detergents, acids, or bases to clean sleeves

because theywill remove the deactivation

layer and require sleeve resilanization.

Sleeves that are very dirty or contain

pyrolyzed residue can be difficult to clean.

Heating borosilicate or quartz sleeves

overnight in amuffle furnace at 550°Cwill

removemost contaminants. Etchingwith a 1:1:1mixture of hydrofluoric acid, sulfuric

acid, and deionizedwater for ten seconds is also very effective. However, heating to