RestekCapillaryColumn InstallationGuide, Section II

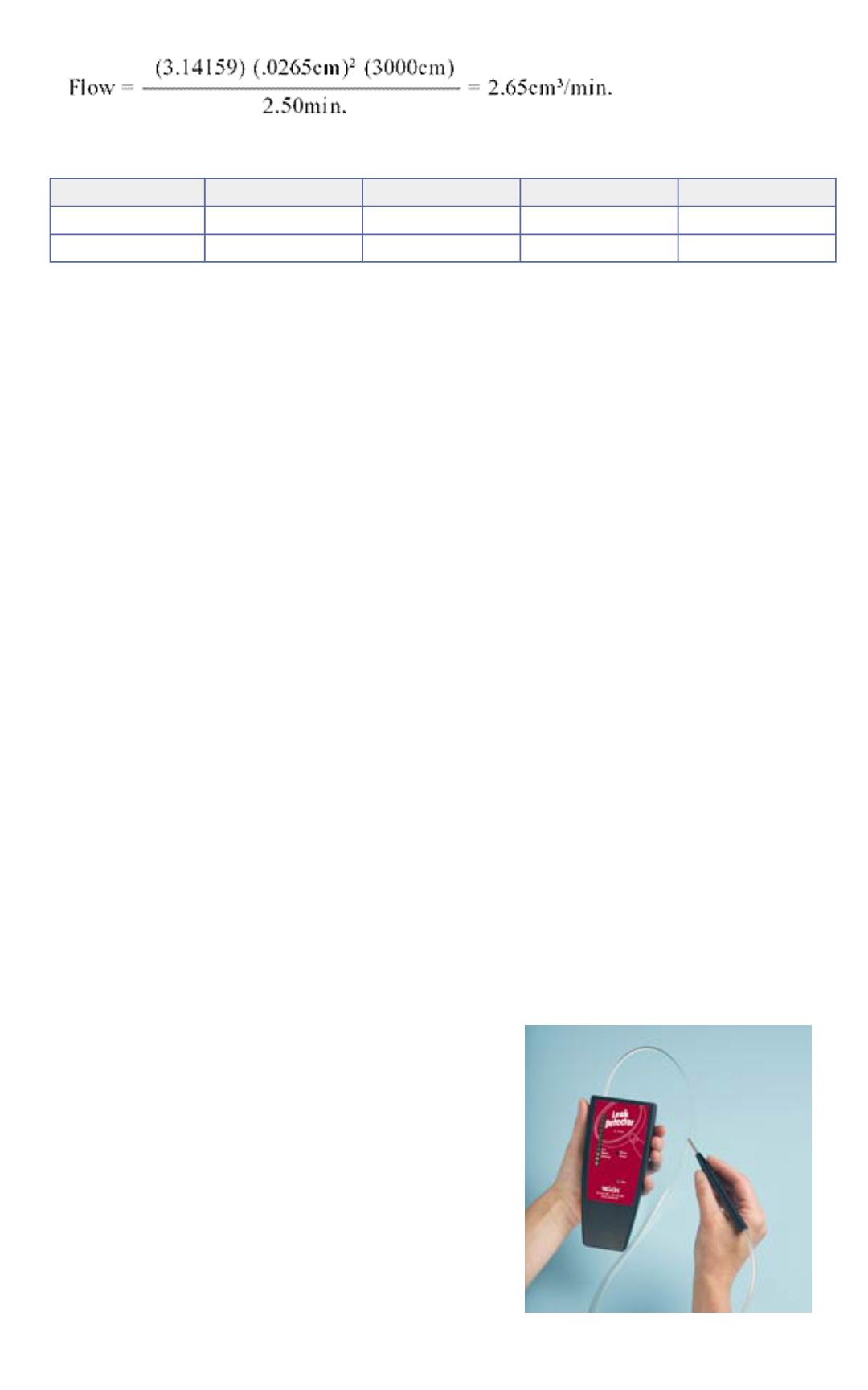

Table III Typical Split Vent FlowRates (50 to1 split ratio)

Carrier gas 0.18mm ID 0.25mm ID 0.32mm ID 0.53mm ID

helium 15cc/min.

35cc/min.

80cc/min.

125cc/min.

hydrogen

30cc/min.

70cc/min.

160cc/min.

250cc/min.

Safety Tip: Always use a split vent trapwhen injecting hazardous or carcinogenic chemicals into a split/splitless inlet

system.

GoodOperatingPractice

Operating a columnwithout carrier gas flow causes irreparable damage to the

stationary phase. Confirm flow by inserting the column outlet into a vial of solvent such

as acetone or isopropyl alcohol prior to installing it into the detector. The appearance of

bubbles at the column outlet confirms carrier gas flow. Allow the column to purgewith

carrier gas for fifteenminutes before installing the column outlet into the detector to

remove any room air that may have diffused inside the column.

Outlet Installation

Install the nut and ferrule to the detector in themanner described in the instrument

manual. Gently insert the column end into the outlet fittingmaking sure that it is not

crushed or scraped against themetal detector parts. Regardless of the GC

manufacturer, a higher degree of inertness and better peak symmetry results if the

column end can be installed 1 to 3mm from the detector jet orifice. Be careful not to

push the column beyond the jet orifice or the column endwill burn in the flame. Some

jets are too narrow to insert the column close to the jet orifice. If this is the case, pull

the column end approximately 2mm away from the narrowed point to prevent flow

occlusion or loss of inertness. Whilemaintaining the correct insertion distance, use a

capillarywrench to tighten the nut approximately one-half turn past finger-tight until

the column is held firmly. The ferrule is tight when the column cannot be pulled from

the fittingwhile applying gentle pressure.

Note— Be cautious when using stainless steel or aluminum-clad columns in gas

chromatographs or GC/MS systems with electrically energized detector jets or orifices.

These columns will conduct electricity and cause a short if the end of the column is

installed too far into the energized detector. Always turn off the electrometer with

Varian, PerkinElmer, and Shimadzu FIDs (since the detector is not grounded) when

installing stainless steel or aluminum clad columns.

Leak-Checking Techniques

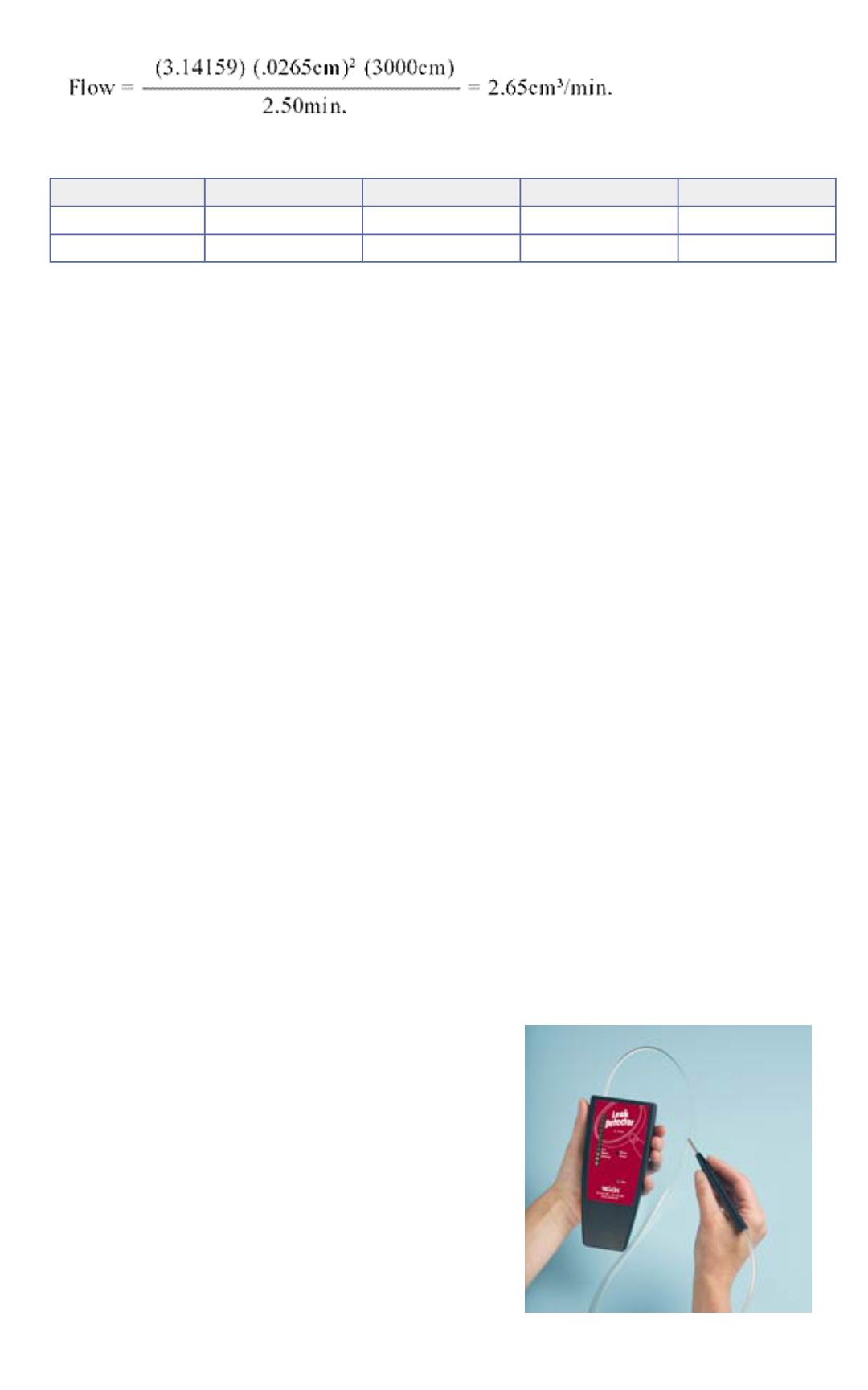

The best way to leak-check a capillary column system is to use a thermal conductivity

leak detector (cat.#22451)*. These portable devices detect minute traces of helium or

hydrogen carrier gas without contaminating the system. Leaks inmass spectrometers

can easily be determined bymonitoring for Mass 28 (N

2

) or 32 (O

2

).*

Never use liquid leak detectors that contain soaps

or surfactants in capillary chromatography. Leaks

draw thesematerials inside the system and

contaminate the column, making high sensitivity

operation difficult. In addition, liquid leak detectors

can cause permanent damage to the capillary

column by depolymerizing the silicone stationary

phase.

Once the system is leak-free, set the injector and

detector temperatures approximately 20°C above

the final operating temperature of the analysis or at

the column'smaximum operating temperature.

Then light or turn on the detector. Caution: Do NOT

exceed themaximum operating temperature of the