GCAnalysis of PetroleumProducts bySimulated

Distillation, UsingMXT

®

SimDistColumns

TheAmericanSociety forTestingandMaterials (ASTM) has

releasedanewgas chromatographic (GC)method for petroleum

distillation, “BoilingRangeDistributionofPetroleumDistillates

in theBoilingRangeof 174°C to700°CbyGasChromatography

(ASTMD6352).”Thismethodextends theboilingpoint range

specified inASTMD2887 (55°C to538°C).Determining the

boiling rangedistributionofdistillate fractionsprovidesmanufac-

turerswithabetter understandingof thecompositionof feed

stocks andproducts related topetroleum refiningprocesses.

Simulateddistillation (SimDist) is a technique inwhich theGC is

calibratedwithalkane standardsof publishedboilingpoints to

performadirect comparison to theboilingpointsof the sample

components. Polyethylene standards such as Polywax

®

655or

Polywax

®

1000,whichcontaineven-numberedhydrocarbons

betweenC20 andC100, are used to calibrate theGC system.The

retention timesof theknownalkanes arecalibratedversus the

publishedboilingpoints, andanalysisof highmolecularweight

fractions arecomparedusing special software.Analyzinghigh-

boilingcompounds (up to700°C) requiresanon-columnor

temperature-programmable injector tominimize injectordiscrimi-

nation, anda flame ionizationdetector (FID).

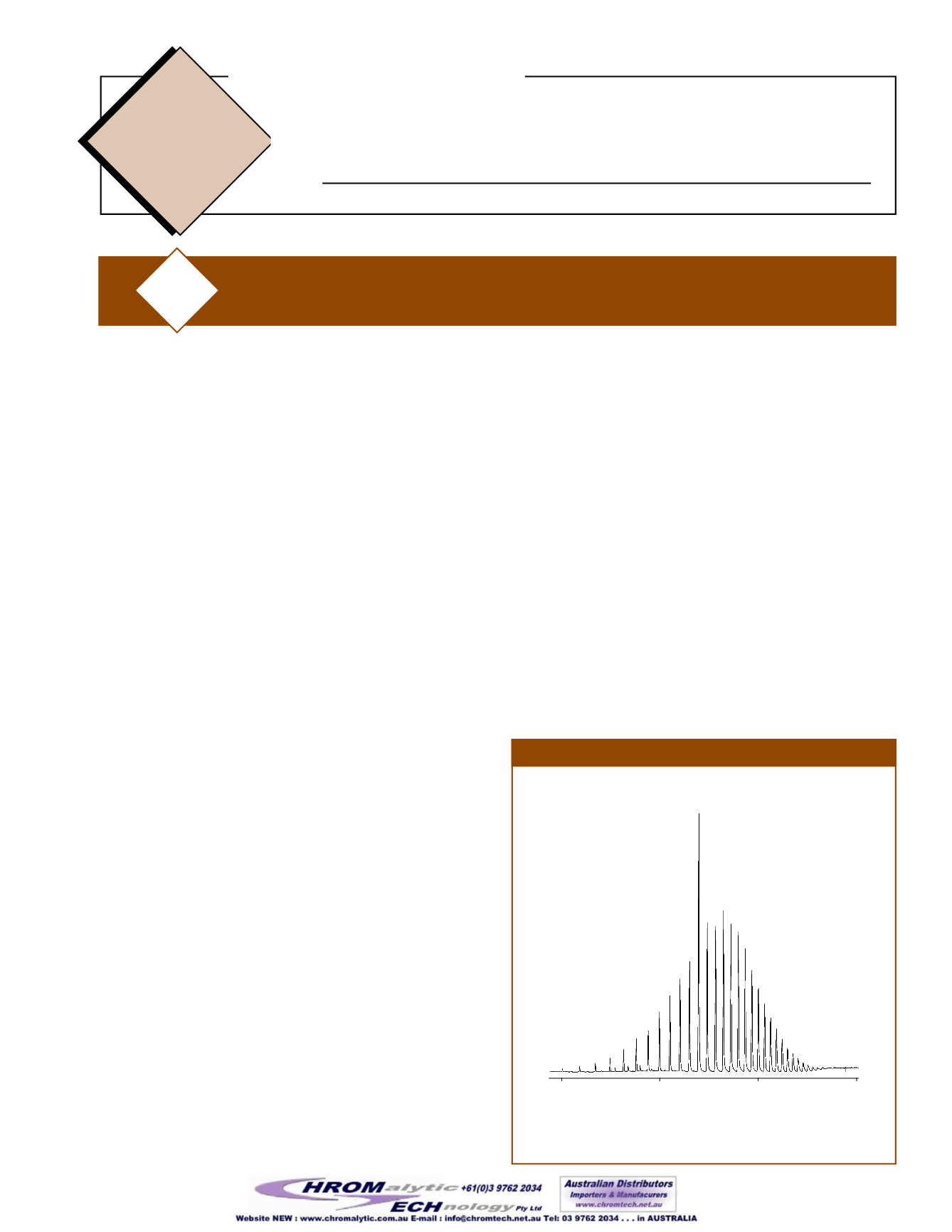

Thecapillarycolumnused for theanalysis isvery important.The

recommendedcolumn is coatedwithanon-polarmethyl silicone

phase that canwithstand repeatedcyclesof high temperatures

(430-450°C).However, thepolyimidecoating thatmaintains the

flexibilityof fused silica tubing rapidlybreaksdownat oven

temperaturesabove360°Cand isunsuitable forhigh-temperature

GC.Aluminum-clad tubingovercomes theproblemsassociated

with thepolyimide, but has itsown limitations.When repeatedly

programmed to temperaturesabove400°C, thealuminum sheath

maybecomebrittle.Themost durableand inert capillarycolumns

availableareRestekMXT

®

columns,whicharemanufactured

usingSilcosteel

®

tubing—ruggedmetal tubing that is treated to

provide the inertnessof fused silica.

The liquidphase in thecolumnalsomustwithstand temperatures

over 400°C,withminimumbreakdownof thepolymer.Thephase

must demonstrate lowbleedand retention time stability that is

repeatablewith temperatureprogrammedanalysis.Themethyl

siliconepolymer in theMXT

®

-1SimDist column is synthesized

todemandingqualitycontrol standardsusingaproprietary

synthesisprocess.Thisprocess eliminates residual catalysts that

couldcausedegradationand increasebleed from thepolymer.The

polymer then is carefully fractionated to remove lowmolecular

weight fragments, providinga tightmono-modal distribution that

results inextremely lowbleed.Thepolymer is fullycharacterized

for long-term reproducibilityusing techniques suchasRI, FTIR,

Kovats Indices,%crosslinking, coatingefficiency, anda five-day

thermal bake-out toensurecolumn longevity. Figure1 shows the

separationofPolywax

®

655onanMXT

®

-1SimDist column.

Although theASTMD6352 recommends amethyl silicone liquid

phase, another phasealsohasgainedacceptancebyanalysts

performing simulateddistillation—acarboranedimethyl

polysiloxane, orMXT

®

-500SimDist polymer.Thishasbeen

designedby incorporatingcarborane into thebackboneof the

methyl siliconepolymer chain topromote thermal stability (see

Figure2).TheMXT

®

-500SimDist stationaryphase is themost

stablephaseavailable forhigh-temperature simulateddistillation

analyses andwill outlast a100%methyl silicone stationaryphase.

Figure3 shows the separationofPolywax

®

655on theMXT

®

-500

column.

However, the trade-off for increased thermal stabilityproduces a

subtle polaritydifferencebetween themethyl siliconeand the

carborane stationaryphase.Thedifference inpolarityof the

stationaryphases causes a shift in thecalculatedboiling range

Figure 1

MXT

®

-1SimDist ColumnDemonstratesExcellent Symmetry

andLowBleed forHigh-Temperature SimDist Calibration.

6m, 0.53mm ID, 0.15µmMXT

®

-1 (cat.# 70101). 1.0µL injection of Polywax

®

655 in CS

2

, cool on-column.

Oven temp.:

40°C to 430°C@ 10°C/min.

(hold 10min.);

Det. temp.:

430°C;

FID sensitivity:

5 x 10

-10

AFS;

Carrier gas:

hydrogen;

Linear velocity:

45cm/sec. set @ 40°C.

10

20

30

40

min.

Petrochemical

RestekCorporation

(800) 356-1688

A

pplicationsnote

Lit. cat.# 59551