environmental

Applications

note

RestekCorporation • (800)356-1688 • (814)353-1300 •

#59544

environmental

List ofMaterials:

Disk (cat.# 26022); Filter (cat.# 26024); Manifolds (cat.#s

26025, 26026, 26027); Dry Prep (cat.#s 26075, 26076);

25mm Filter (cat.# 26073). If using glass filter beads, see

end

note

for procedural modifications.

Sample Preparation:

1.

Adjust sample to pH 2.0 with 6NHCl

2.

If sample is high in suspended solids, allow solids to

settle. When adding the sample, tilt the sample

container to allow particulates to settle on one side.

This is suggested to aid in the decanting of the liquid

portion of the sample.

ExtractionDiskConditioning:

Proper disk conditioning is critical for a successful extrac-

tion. Conditioning provides a good interface between the

sorbent and the sample matrix. Failure to condition the disk

properly may result in erratic and low recoveries.

1.

Place disk on manifold, ripple side up. Connect

reservoir securely to disk base.

2.

Place the Resprep

™

Flow Filter in the bottom of

the reservoir, flush with the edge of the glass.

3.

Wash the disk with 25mL of n-hexane.

Note:

Always run solvents down the sides of the

glassware when washing or eluting. Apply a light

vacuum (~5in. Hg) and pull approximately 1mL

through the disk. Vent the vacuum and allow the

disk to soak for 2 minutes.

4.

Apply vacuum to pull the remaining solvent

through the disk. Allow the disk to dry.

Extraction of Oil and Grease fromWastewater

Using US EPA Method 1664 and Resprep™

Oil and Grease SPE Disks and Flow Filters

Increasing environmental concerns about the effects of

released chlorofluorocarbons (CFCs) in the atmosphere, and

in an effort to reduce discharges during routine laboratory

procedures, the US Environmental Protection Agency (EPA)

has mandated the elimination of Freon

®

(CFC-113) extrac-

tion solvent for industrial waste samples. This has recently

resulted in the release of an alternative procedure for US EPA

Method 413.1—the US EPAMethod 1664, Oil and Grease

Analysis in Wastewater. The updated method describes an

n

-hexane liquid-liquid extraction and allows use of alter-

native extraction and concentration techniques such as SPE

if the performance specifications of the method are not met.

The

n

-hexane extraction process has several difficulties. As

with all liquid-liquid extractions, emulsions are problematic.

With industrial discharge samples, this problem may become

extreme and result in poor sample partitioning or samples

too viscous to process at all. Because

n

-hexane is lighter

than water, it makes routine separatory funnel processes

difficult to perform. Fortunately, some of these difficulties

may be overcome using the SPE procedure.

By decanting the supernatant from the sample first and using

an appropriate prefilter, most complex samples can be

extracted in less than an hour. The SPE system also can be

automated using vacuum manifolds. This allows simulta-

neous processing of up to six samples, thereby improving

sample throughput and lab efficiency.

The following instructions are general guidelines for SPE

extraction of oil and grease from wastewater. Sample

volume, solvent type, pH adjustment, and conditioning may

be changed to adapt to specific methods as needed.

Please note:

Thismethod is based on the US

EPAMethod 1664, but is not intended to replace

or substitute the method.

Please refer directly to the published EPA

method for additional information for the prepara-

tion of samples to be analyzed according to EPA

Method 1664.

EPA methods are available from NTIS (National

Technical Information Service), U.S. Department

of Commerce, Springfield, VA 22161, phone:

(703) 487-4650.

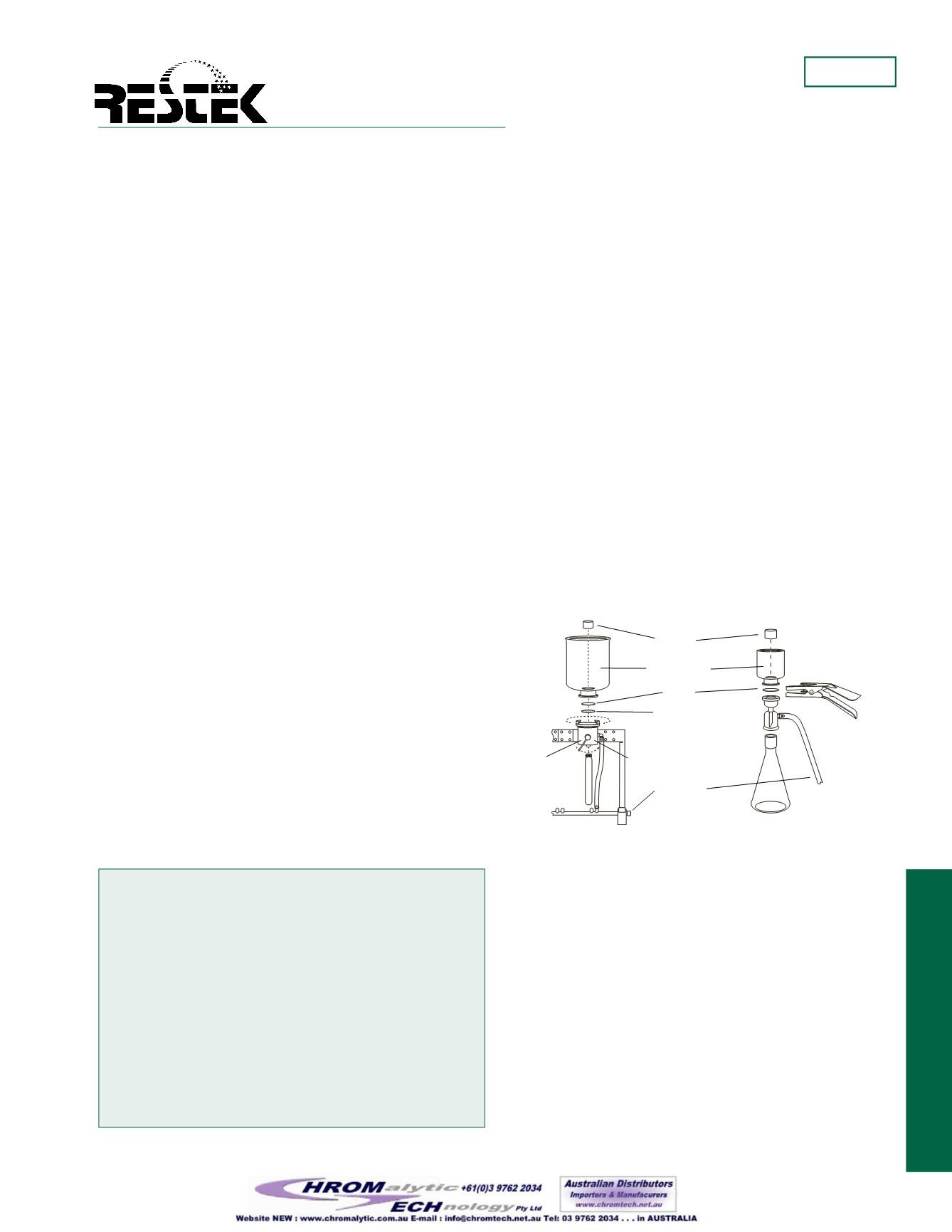

Option 1: Vacuum

Manifold

Option 2: Filtration

Apparatus

Flow

Filter

Disk

Vacuum

Reservoir

Wash

Screen

Elute