~

f.

" i

~'+H~-I-I-H

+111-1-1"'-1 +-11-1-1-1-1

I~I-H

H-1111 11

1

!1-

M A D E IN

~USTRAUA ~

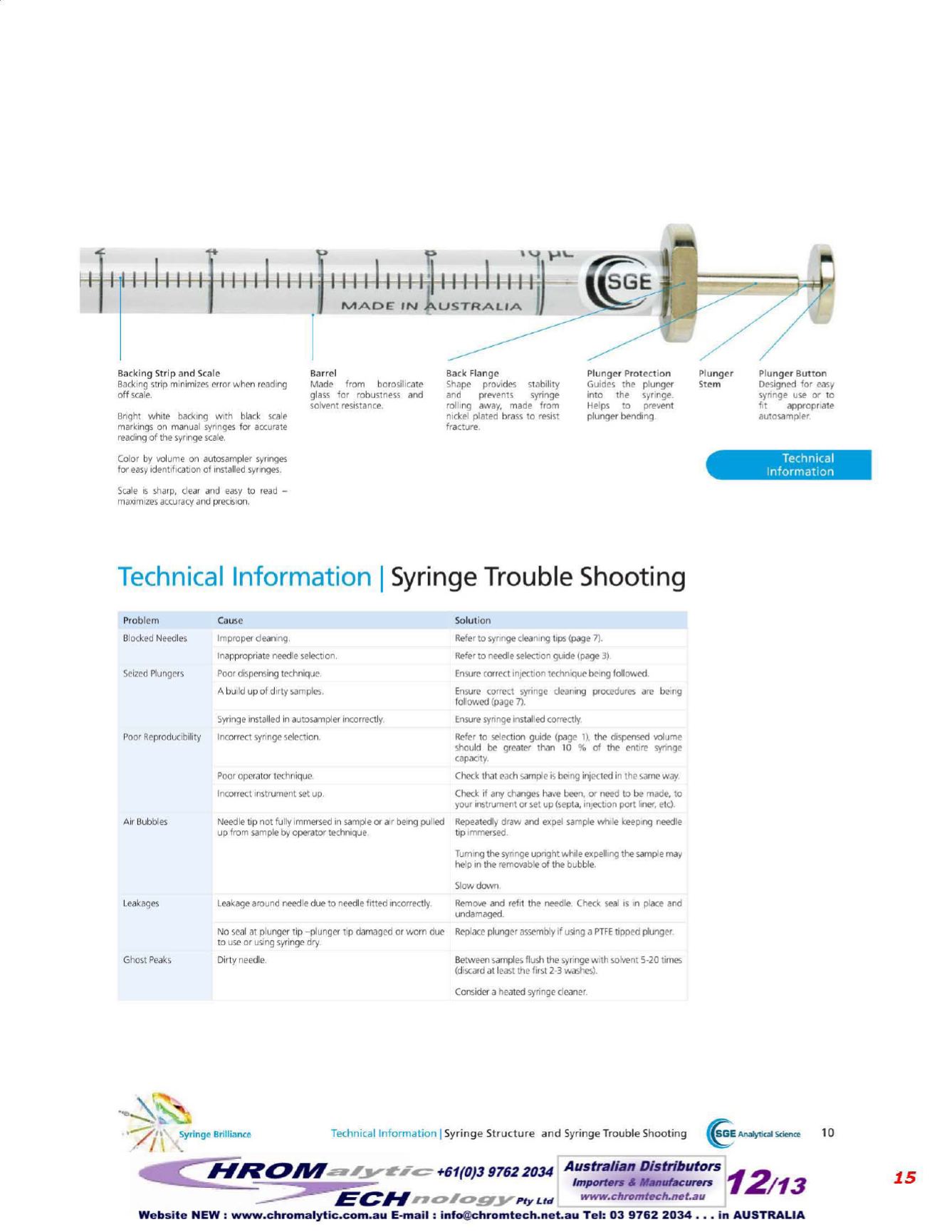

Backing Strip and Scale

BacKing strip minimizeserror when reading

offscale

Bright white backing wrth black scale

markings on manual syringes for accurate

readingof the syringescale

Barrel

Made from borosilicate

glass for robustness and

sojvent resistance.

Back Flange

Shape provides stability

and prevents syringe

rolling away, made from

nickel plated brass to resist

fracture

Plunger Prot ection

Guides the plunger

Into the syringe.

Helps 10 prevent

plunger bending

Plunger

Stem

Plunger Button

Designed for easy

syringe use or to

fit

appropriate

autosampler

Color by volume on autosampler syringes

for easy identification of installed syringes

Technical

Information

Scale is sharp, clear and easy to read –

maximizesaccuracy and precision

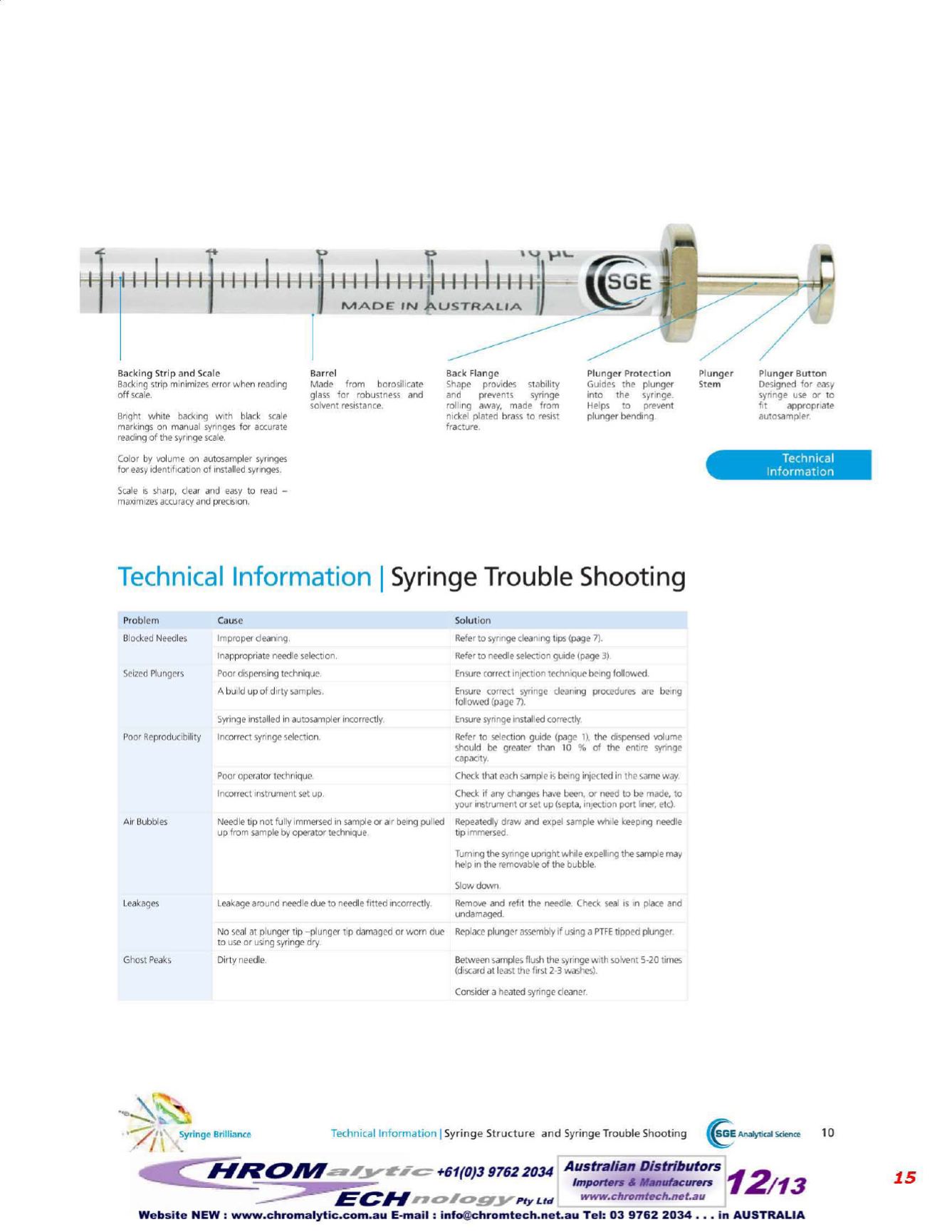

Technical Information

I

SyringeTrouble Shooting

Syringe installed in autosamoler incorrectly

PoorReproducibility Incorrect syringeselection

Problem

Blocked Needles

Seized Plungers

Air Bubbles

Cause

Improper cleaning.

Inappropriateneedle selection.

Poor dispensing technique.

A build up of dirty samples.

Poor operator technique

Incorrect instrument set up

Needle tip not fully immersed in sampleor air being pulled

up fromsample byoperator technique

Solut ion

Refer to syringecleaning nos (page 7)

Refer to needle selectionguide (page 3).

Ensure correct injection techniquebeing followed

Ensure correct syringe cleaning procedures are being

followed (page 7).

EnsuresYringe Installed correctly

Refer to selection guide (page 1), the dispensed volume

should be greater than 10

%

of the entire syringe

cepacrty

Check that eachsample isbeing injected in the sameway

Check if any changes have been, or need to be made, to

your instrument or set up (septa, injection port liner, etc)

Repeatedly draw and expel sample whi le keeping needle

tip immersed

Turning the syringe upright whileexpelling thesamplemay

help in the removableof thebubble.

leakage around needledue to needle fitted incorrectly

Leakages

Slow down

Remove and refit the needle. Check seal is in place and

undamaged

No seal at plunger tip - plunqer tip damaged or worn due Replaceplunger assembly if using aPTFEtipped plunger.

to use or using syringe dry.

Ghost Peaks

Dirty needle

Between samples flush thesyringewithsolvent

5-20

times

(discard at least the first

2-3

washes)

Consider aheated syringe cleaner

15

10

G

Analytical Science

,.,..-....,.,.--...."....---,

Technical Information

I

Syringe St ructure and SyringeTrouble Shooting

Syringe Brilliance

'.

!

...

~

...

.-;//;"

. I

...:::

HROIIII""" .J'~Ic:

+61(0)3 97622034 Australian Distributors

1'''''

-

Importers

&

Manufacurers

~/13

____

ECI-lI71~I~g"y"PtYLtd

Website NEW :

E-mail :

t.au Tel: 03 9762 2034 • •• In AUSTRALIA