483

M

MILLS

Planetary Ball Mill

Grinding and Mixing Examples:

Before

After

Wood Fiber

Feather

Mineral

Metal Plate

Technical Data

Electrical requirements

100-120/200-240 Volt 50/60 Hz

Motor Power

180 Watt

Transport Data

Dimensions closed w x d x h

Ca. 759x645x550mm

Weight

34kg

Features/Performance

Working principle

Impact, Friction

Feed size maximum

<

10mm

Number of grinding jars

8/4/2

Max. volume of each grinding jar

250ml

Min. volume of each grinding jar

10ml

Max. end fineness

<1

µ

m; <0, 1

µ

m for colloidal grinding

Adjustment of grinding duration

Digit. adjustable

Start / Stop Function

1

Setting of grinding time

Digital, 00:00 to 99:59

Interval operation

yes, with direction reversal

Pause time

00:00 to 99:59

Speed Ratio

1:-2; 1:-2.5; 1:-3

Sun wheel speed

50 - 400 min-1

Effective sun wheel diameter

360mm

Applications:

●

Flour

●

Wood fibres

●

Plant Materials

●

Seeds

●

Tobacco

●

Bentonite

●

Concrete

●

Gypsum

●

Sand

●

Stone

●

Cement clinker

●

Hair

●

Bones

●

Tissue

●

Carbon fibres

●

Plastics

●

Paints and lacquers

●

Catalysts

●

Pigments

●

Polymers

●

Cellulose

●

Glass

●

Hydroxyapatite

●

Kaolin

●

Ceramic oxides

●

Quarz

●

Clay minerals

●

Ores

●

Semi-precious stones

●

Cole

●

Coke

●

Alloys

●

Metal oxides

●

Slags

●

Sludges

●

Electronic scrap

●

Organic and inorganic waste

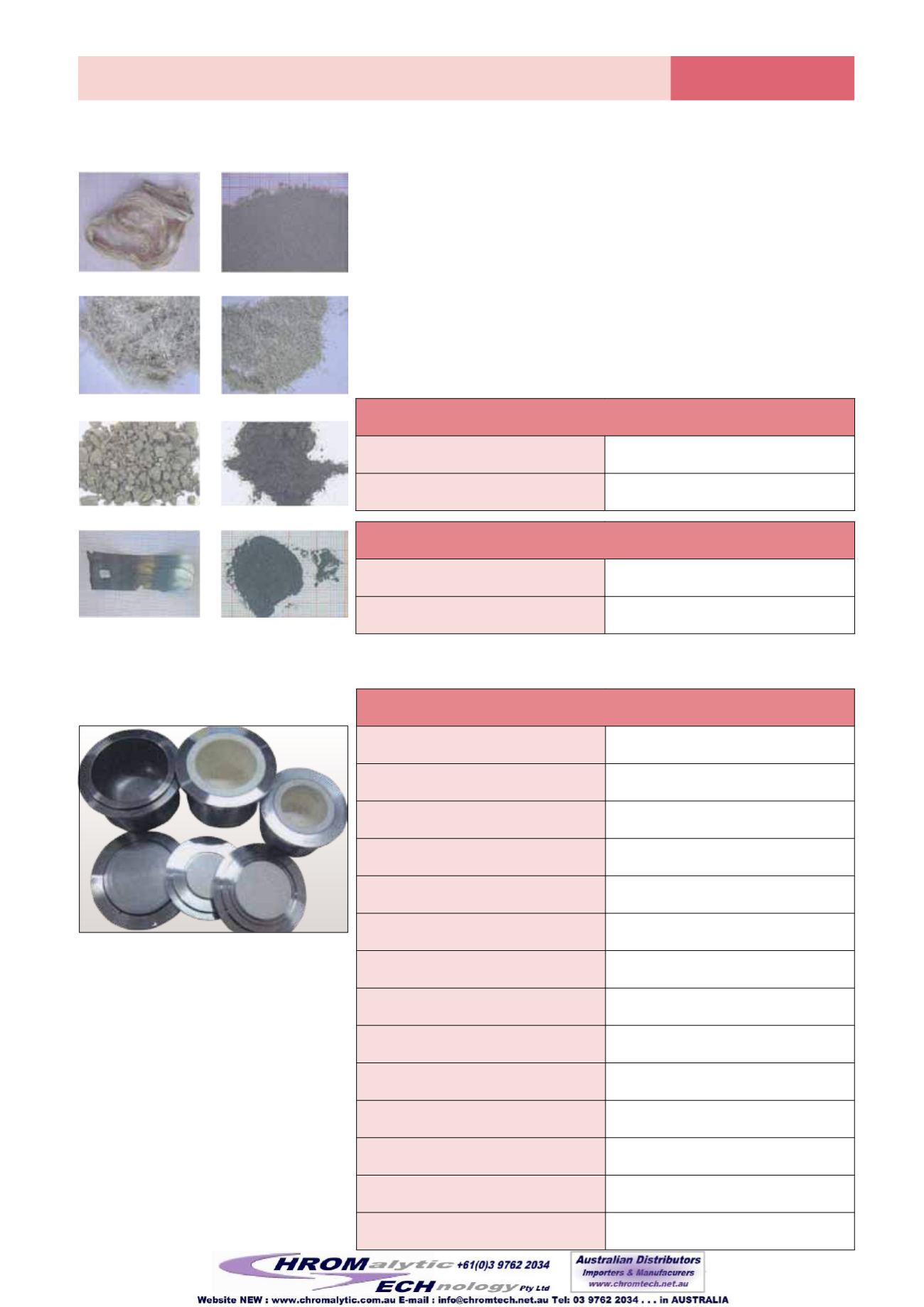

Specifications:

Grinding jars available with different

liner:

●

Stainless steel

●

Hardened steel

●

Tungsten carbide

●

Agate

●

Sintered corundum

●

Zirkonium oxide

Features of grinding jars:

The grinding jars are built from one block

of steel or built with a stainless steel

protective jacket with liner from the

above materials.

MRC grinding jars unique advantages:

●

Safe, with stainless steel protective

jacket

●

Easy opening according to gap

between lid and jar

●

Self-centring base of grinding jar

●

Gas-tight and dust-proof sealed by

o-ring

●

Labels field.