475

M

MILLS

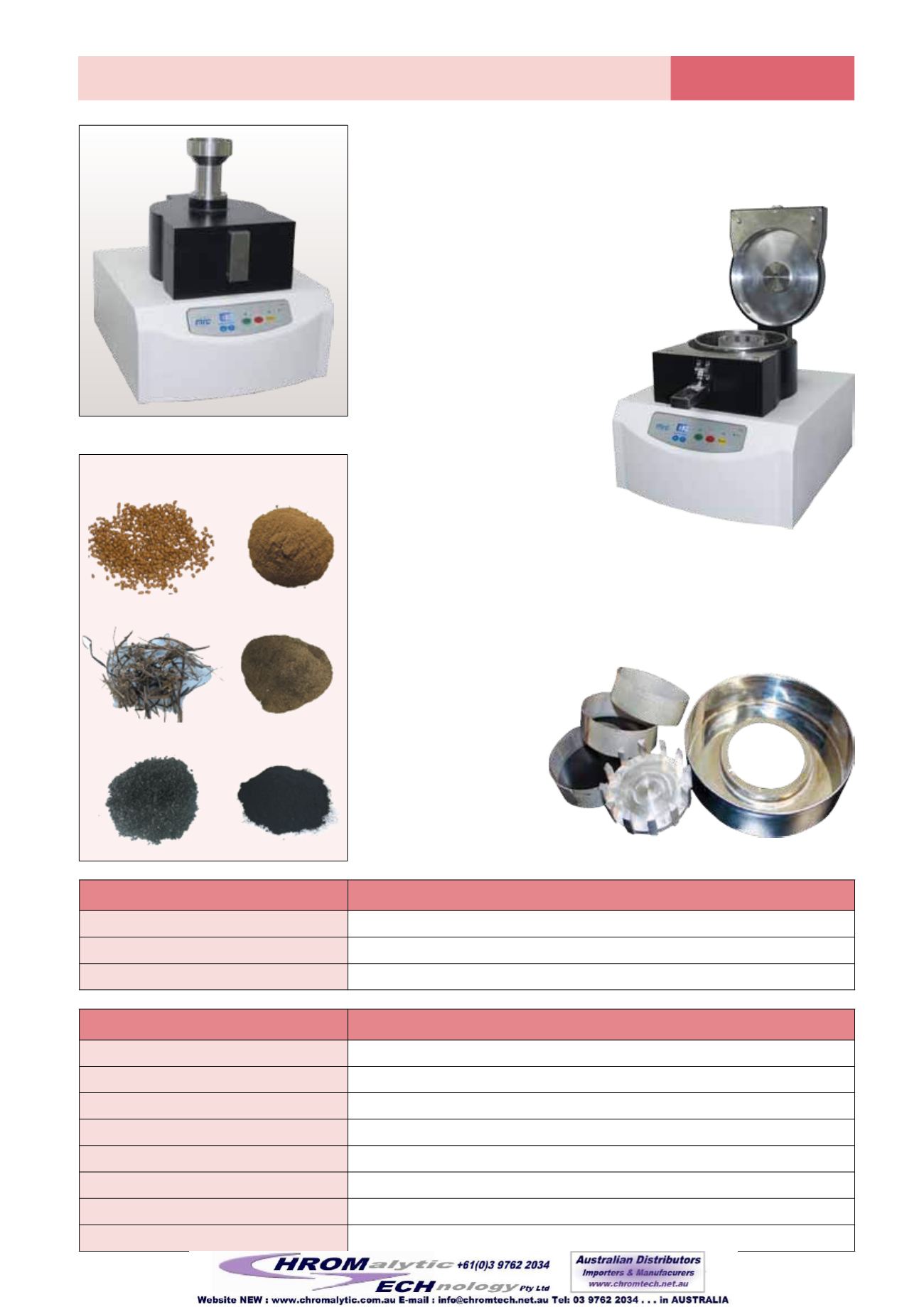

Fast Impact Mill

FAM-100

●

Rapid reduction from 15 mm to 40 um

●

Quick and easy to clean

●

Full

range of accessories

●

Digital speed setting

FAM-100, Fast Mill with flexible speed setting

Work principle:

The sample is grounded to powder by impact and

shearing effects. First ,the sample is feed to the

hopper, then thanks to strong centrifugal force, the

sample is thrown against the wedge-shaped

rotor, where the sample is crashed. Then the sample

goes through the rotor & the fixed ring sieves for final

grounding, you can manually stop the

machine and collect the sample.

Advantages:

●

Wide range of accessories including

various collection and feeding

systems, rotors and sieves.

●

Variable speed setting between

7,000-20,000 rpm.

●

Easily exchangeable grinding and sieve

parts.

●

Final product size can be determined by using ring sieves with aperture

sizes from 0.08-8mm.

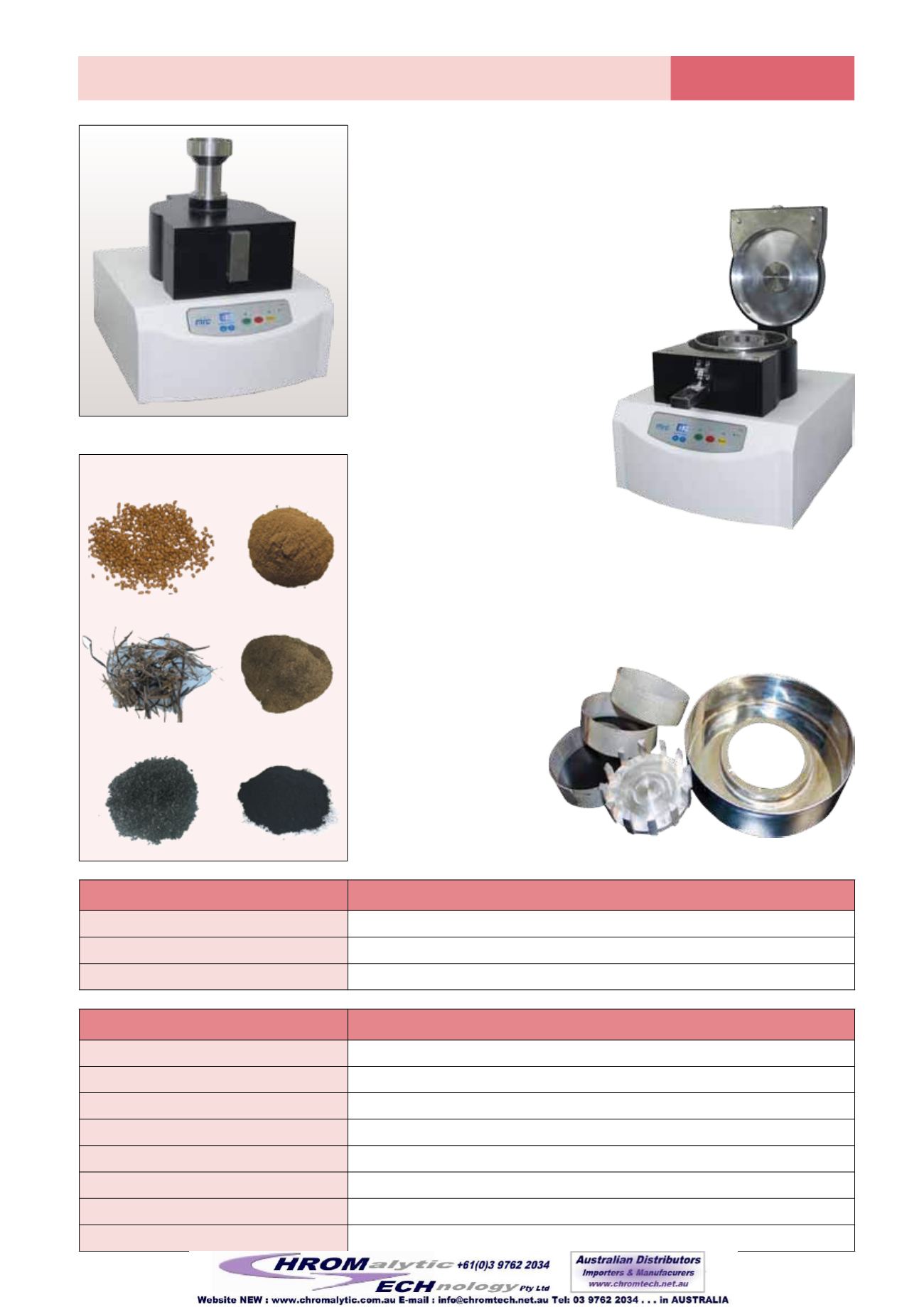

Various rotor and ring sieves

●

6/12/24 tooth rotor are available

●

The rotor can be made of stainless steel or pure titanium

●

Sieves may come in standard ring model, reinforced rim and distance

sieve.

Grinding Examples

Before

After

Herbal medicine

Coal

Feed

Technical Data

FAM-100

Electrical details

230V/50 Hz

Dimensions WxHxD

400x460x450mm

Net weight

35kg

Features/Performance

FAM-100

Application field

soft, medium-hard, brittle, fibrous

Feeding size

< 15 mm

The End-fineness

< 40

µ

m

The speed setting

7,000-20,000 rpm

The collecting cassette volume

standard 900ml

The rotor speed setting

7,000-20,000 rpm

Rotor peripheral speed

29.83-99.43m/s

Rotor diameter

95mm

Applications

●

Agriculture

●

RoHS

●

Environment

●

Coal

●

Soil

●

Chemistry / plastics

●

Electronics

●

pharmaceuticals