487

M

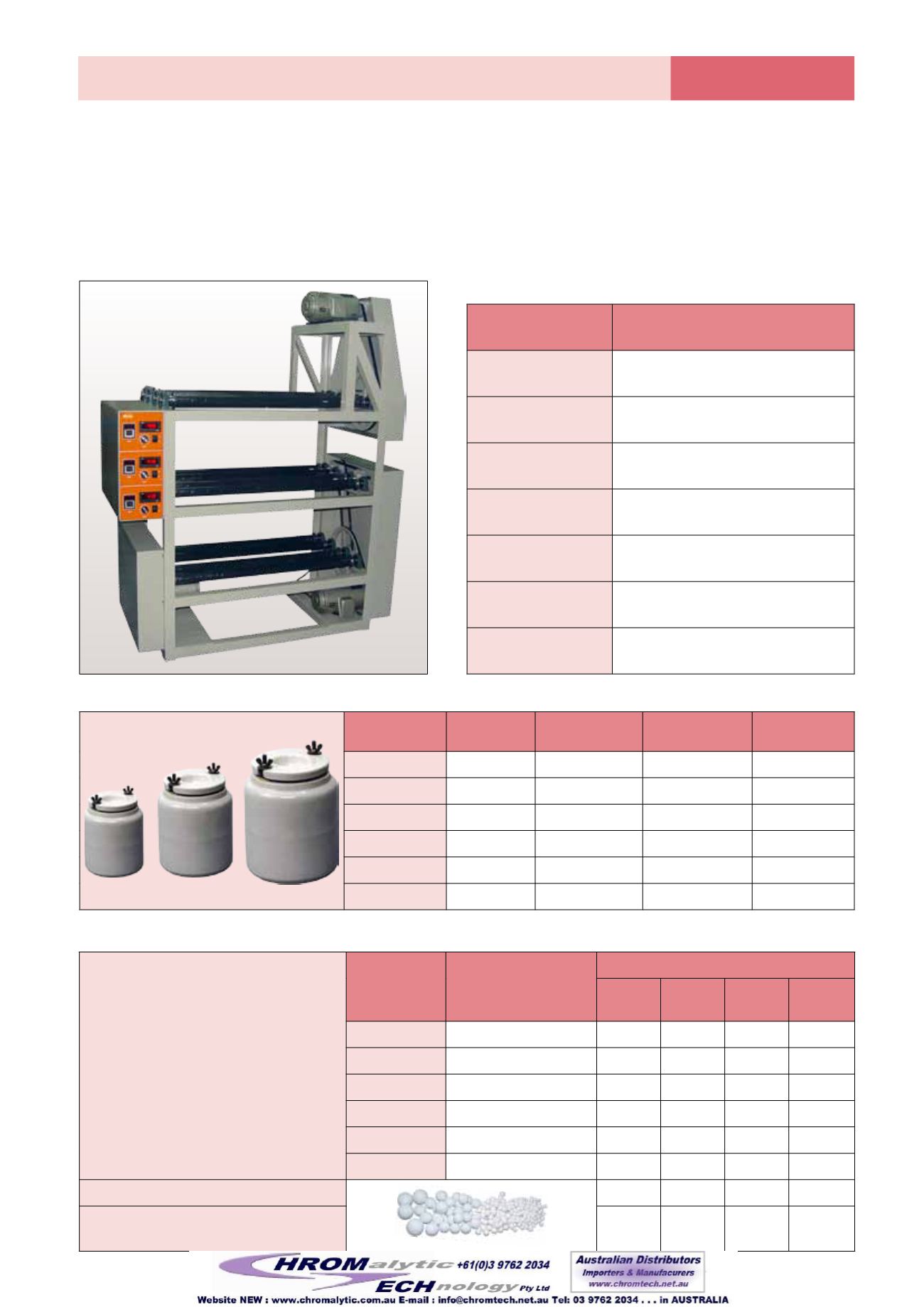

MILLS

Model

RJM-304

Speed (RPM)

0~420

Pot size (cm)/DIM

Ø

9~

Ø

24

Roller

Ψ

(cm)

Ø

5

Motor

400W

Timer (hrs)

0.1~99.9

Outline size (cm)

W142xD68xH182

Power

AC220V, 50/60Hz

RJM-304, Large Ball Mill, 3 Stages

RJM-304

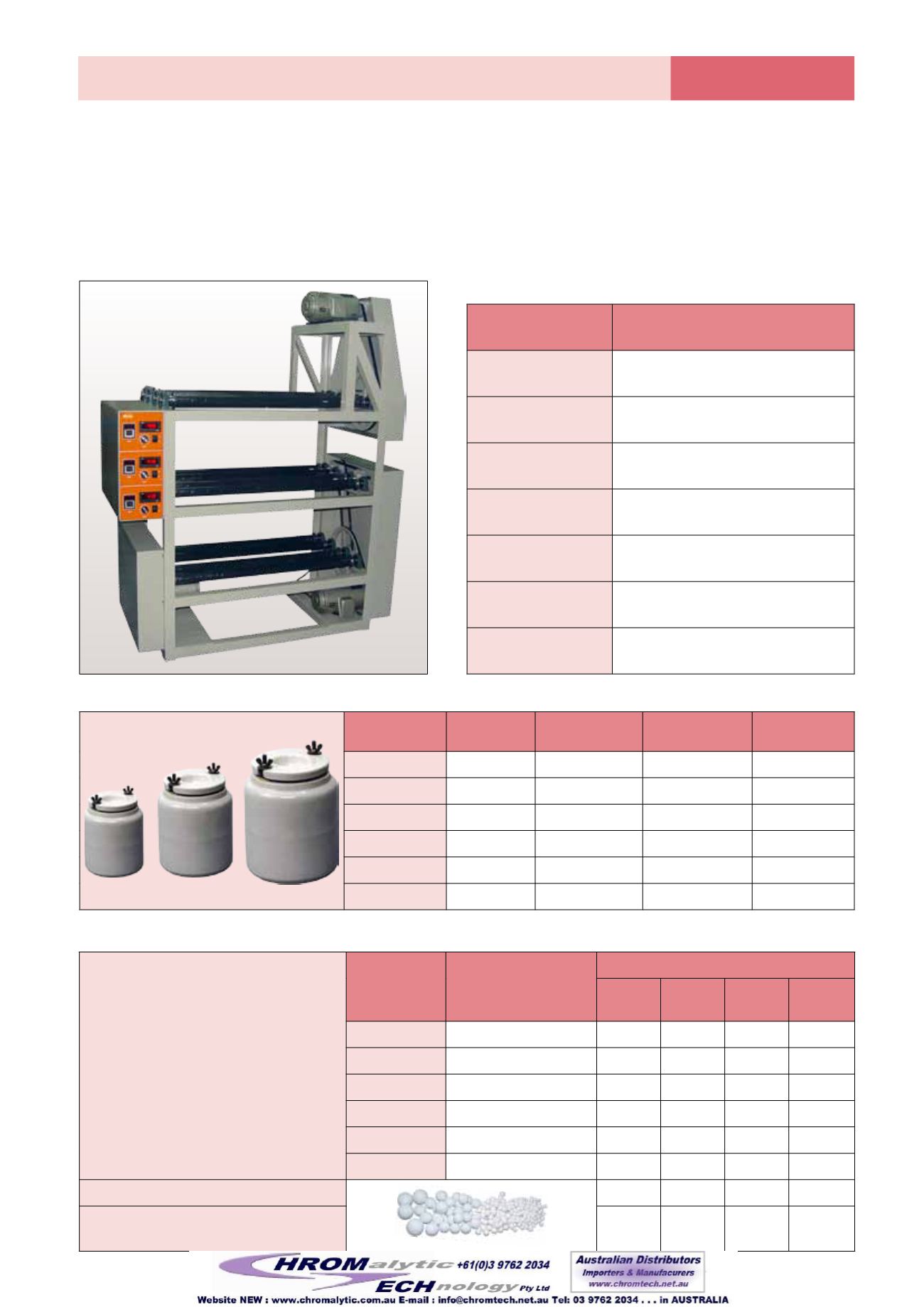

Size

(mm)

Total Cap.

Useful Cap.

Speed

rpm

Model

Ø

120x150

800

500

130

Mill pot 4

Ø

150x180

1,600

1,000

110

Mill pot 5

Ø

180x210

2,800

2,000

90

Mill pot 6

Ø

210x240

4,500

3,000

85

Mill pot 7

Ø

240x300

7,500

5,000

75

Mill pot 8

Ø

300x360

15,500

10,000

60

Mill pot 10

Balls for Mill Pot

Recommendations

for ball fillings

Mill pot no.

Capacity

approx. ml.

Ball

Ø

42K-9

9mm

42K-15

15mm

42K-20

20mm

42K-30

30mm

4

500

0.05kg 0.1kg 0.1kg

5

1000

0.1kg 0.2kg 0.2kg

6

2000

0.2kg 0.4kg 0.4kg

7

3000

0.3kg 0.6kg 0.6kg

8

5000

0.5kg 1.0kg 1.0kg

10

10000

0.5kg 1.5kg 1.5kg 1.5kg

No. of balls per kg approx.

425 pcs.

130 pcs.

90 pcs.

16 pcs.

Bulk density of balls per Liter approx.

1885g 1930g 2000g 1800g

Mill Pots

Roll Jar Mills, Mill Pots, Balls

●

High efficiency –

Due to the relatively slow rotational speed but large mass of media, more of the energy goes into

milling and less wasted as heat.

●

Narrow particle distribution –

Solids milled in tumble mills are normally so fine and consistent in size that it’s rare to

require classification.

●

Repeatable results –

Mill operating parameters including rotational speed, media size and milling duration can be

independently controlled with known effect on the final results.

●

Low temperature –

Because of the high efficiency of milling and low heat generation, the solids will not be exposed

to high temperatures. For extremely heat sensitive products, cooling jackets can be provided on the mill cylinder.

●

Chemical containment –

Solids are sealed and contained inside the mill, protecting the environment and operators.