138

VALVES

StainlessSteelSampleLoops

These high quality stainless steel sample loops have burr-free,

square-cut ends toensureaflush connection to valveports. The size

designations of loops are nominal. The actual volumes can differ

from the theoreticaldesignationsbecauseof the0.001” (±0.025mm)

toleranceof themetal tubingbore.

Accuracy of largemetal loops (1.0mm, 0.040”bore) is about ±5%,

intermediate loops (0.5mm, 0.020” bore) ±10%, and small loops

(0.2mm, 0.007”bore) ±30%.

Sinceboth standards andunknowns areusually analyzedusing the

samesample loop, knowledgeof theactual, accuratevolume is rarely

needed. Ifthesample loopvolumemustbeknown, it isbesttocalibrate

the loop inplaceon the valve so the flowpassages in the valve are

also taken into account. An alternative to calibration is touse adual

mode injector andpartial-fillingmethodof loading. See the“Sample

LoopLoading”ApplicationNoteonpage129.

Model 7725 Injector loopsarenot interchangeablewith loops for the

model 7125.Theportangle for the7725 is30°whereas theportangle

for the7125 is 20° requiring the loops tohaveadifferent shape.

Model 8125Micro-ScaleSample Injector requiresspecial loops in the

5.0µL to50µL range. The8125 sample loops aremadewith0.5mm

(0.020”)OD tubing.

APPLICATIONNOTE

How toProperly Install SampleLoops: Stainless Steel

Stainless steel sample loopsare suppliedwithfittings that arenot swaged

onto the tube. It is important that the loopbecompletelybottomed in the

injectorportbefore the ferrule is swagedonto the tube. Thedepthof the

tubingholesmayvary slightly fromport toport and fromvalve tovalve.

Afittingmadeup inoneportmay leavea small cavity inanotherport.

Thecavitycauseshighdispersionandpeakdistortion suchas fronting,

tailing, orbroadening. It isgoodpractice to label loopends so theywill

be replaced in the same, respectiveports thatwereused in swaging

the ferrules.Hint: swaging ferrules separatelyoneach side, intoeach

respectivevalveportmakes loop installationeasier.

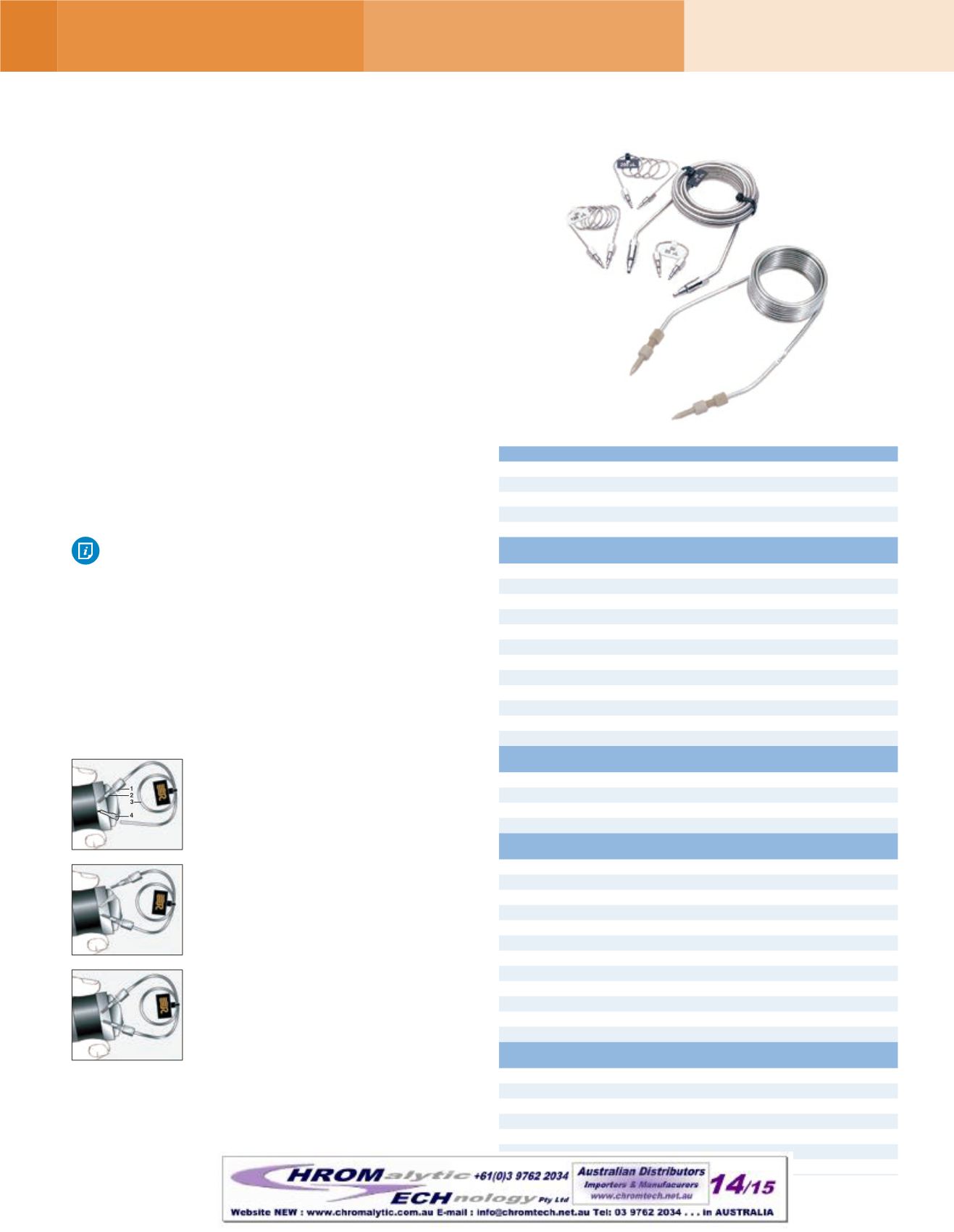

To install the sample loop:

a) Takeoneendof the loopandplace thenut

(1) and ferrule (2) onto the tubing (3)with

the threadedportionof thenut and tapered

portionof the ferrule toward theend. See

FigureA.

b) Insert the tubing intoport (4).Confirm that

the tubing isbottomed in the valveport as

shown inFigureA.

c) Whilefirmlypressingdownon the tubing,

hand-tighten thenut as tight aspossible.

d) With the IDEXWrench (seepages33and144),

designedespecially for fittings, tightenone

quarter turnpast finger tight. Remove the loop

toconfirm the ferrule is swagedonto the tube.

e) Repeat stepsa-dwith theother endof the

loopwhile the swagedend remainsoutside

the valveport. SeeFigureB.

f) Reinstall eachendof the loop to their

respectiveports. SeeFigureC.

Figure1

Cut-away view

of stainless steel sample

loop installation

A

C

B

PartNo.

Volume

Tubing

RHEODYNE

®

STAINLESSSTEEL LOOPSFORMXT715-000

7755-300

5µLSample Loop

0.18mm (0.007”) ID x 1/16”OD

7755-301

10µLSample Loop

0.30mm (0.012”) ID x 1/16”OD

7755-302

20µLSample Loop

0.30mm (0.012”) ID x 1/16”OD

7755-303

50µLSample Loop

0.51mm (0.021”) ID x 1/16”OD

7755-304

100µLSample Loop

0.51mm (0.021”) ID x 1/16”OD

RHEODYNESTAINLESSSTEEL LOOPSFOR7125, 7010 INJECTIONVALVES

(DONOTUSEFOR7725)

7020

5µLSample Loop

0.18mm (0.007”) ID x 1/16”OD

7021

10µLSample Loop

0.30mm (0.012”) ID x 1/16”OD

7022

20µLSample Loop

0.51mm (0.020”) ID x 1/16”OD

7023

50µLSample Loop

0.51mm (0.020”) ID x 1/16”OD

7024

100µLSample Loop

0.51mm (0.020”) ID x 1/16”OD

7025

200µLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7026

500µLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7027

1.0mLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7028

2.0mLSample Loop

1.0mm (0.040”) ID x 1/16”OD

7029

5.0mLSample Loop

1.0mm (0.040”) ID x 1/16”OD

1876

10mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

1877

20mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

RHEODYNESTAINLESSSTEELLOOPSFOR3725-038,

3725I-038 INJECTIONVALVES

3065-018

2.0mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

3065-019

5.0mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

3065-023

10mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

3065-025

20mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

RHEODYNESTAINLESSSTEEL LOOPSFOR7725, 7725I, PR/EV700-100,

PR/EV703-100,MXMODULE INJECTIONVALVES (DONOTUSEFOR7125)

7755-020

5µLSample Loop

0.18mm (0.007”) ID x 1/16”OD

7755-021

10µLSample Loop

0.30mm (0.012”) ID x 1/16”OD

7755-022

20µLSample Loop

0.30mm (0.012”) ID x 1/16”OD

7755-023

50µLSample Loop

0.51mm (0.020”) ID x 1/16”OD

7755-024

100µLSample Loop

0.51mm (0.020”) ID x 1/16”OD

7755-025

200µLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7755-026

500µLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7755-027

1.0mLSample Loop

0.76mm (0.030”) ID x 1/16”OD

7755-028

2.0mLSample Loop

1.0mm (0.040”) ID x 1/16”OD

7755-029

5.0mLSample Loop

1.0mm (0.040”) ID x 1/16”OD

1876

10mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

1877

20mLSample Loop

2.0mm (0.080”) ID x 1/8”OD

RHEODYNESTAINLESSSTEEL LOOPSFOR8125 INJECTOR

(USE7755-024TO7755-029FORVOLUMES>50µL)

8020

5µLSample Loop

0.20mm (0.008”) ID x 0.020”OD

8021

10µLSample Loop

0.20mm (0.008”) ID x 0.020”OD

8022

20µLSample Loop

0.25mm (0.010”) ID x 0.020”OD

8023

50µLSample Loop

0.30mm (0.012”) ID x 0.020”OD

8125-084

Ferrules for 0.020” (0.5mm) Tubing

8125-086

Ferrules for 0.020” (0.5mm) Tubing, 4-pk

Seepage140 forValco-compatible stainless steel sample loops.

Sample Loops