Introduction toBiodiesel

Today, as oil prices climb and pollution levels soar,

there is significant worldwide interest in alternative

fuels. Biodiesel is one of themost popular alterna-

tive fuels available today. Itmay be used in engines,

either pure or blended with diesel fuel, to reduce

exhaust pollutants. It can be produced easily from

sunflowers, soy, rapeseed, tallow, lard, yellowgrease,

and other sources. Chemically, it is the product

obtainedwhen a vegetableoil or animal fat is react-

edwithanalcohol in thepresenceof acatalyst, such

as sodiumorpotassiumhydroxide, toproduce fatty

acidmethyl esters.

Methods used to test the quality of biodiesel fuels

canbe categorized into three types basedon the tar-

getcompounds:ASTMD6584andEN14105 test for

total glycerin, EN 14103 tests for fatty acidmethyl

esters (FAMEs), and EN 14110 tests for residual

methanol. Thesemethodsmay be performed using

either fused silicaormetal columns, but the column

chosenmusthaveextremelyhigh temperature toler-

ance. Restek offers both fused silica and metal

columns designed specifically for high temperature

biodiesel analysis. These columns, the Rtx®-

Biodiesel TG,MXT®-Biodiesel TG, Stabilwax®, and

Rtx-1®column lines,offeroutstandingperformance

for biodiesel testing.

AnalyzingTotal Glycerin inBiodiesel

Rtx®-BiodieselTGFusedSilicaColumns

Glycerin inbiodiesel falls out of solution, causinggumming in fuel systems and

malfunctioning of engine parts, which eventually leads to inferior engine per-

formance. Total glycerin presents itself in two forms: free glycerin and bound

glycerin in the form of glycerides. Derivatization is required for analysis, and

both ASTM D6584 and EN 14105 use N-methyl-N-trimethylsilytrifluoroac-

etamidederivatization reagent.

A10mx0.32mm IDRtx®-Biodiesel TG columnwith a2mx0.53mm ID reten-

tiongap is ideal for glycerin analysis.The retentiongap is factory coupledusing

Restek’s uniqueAlumaseal™ connector (Figure 1).This innovative connector is

leak-tight and low dead volume,making it advantageous for high temperature

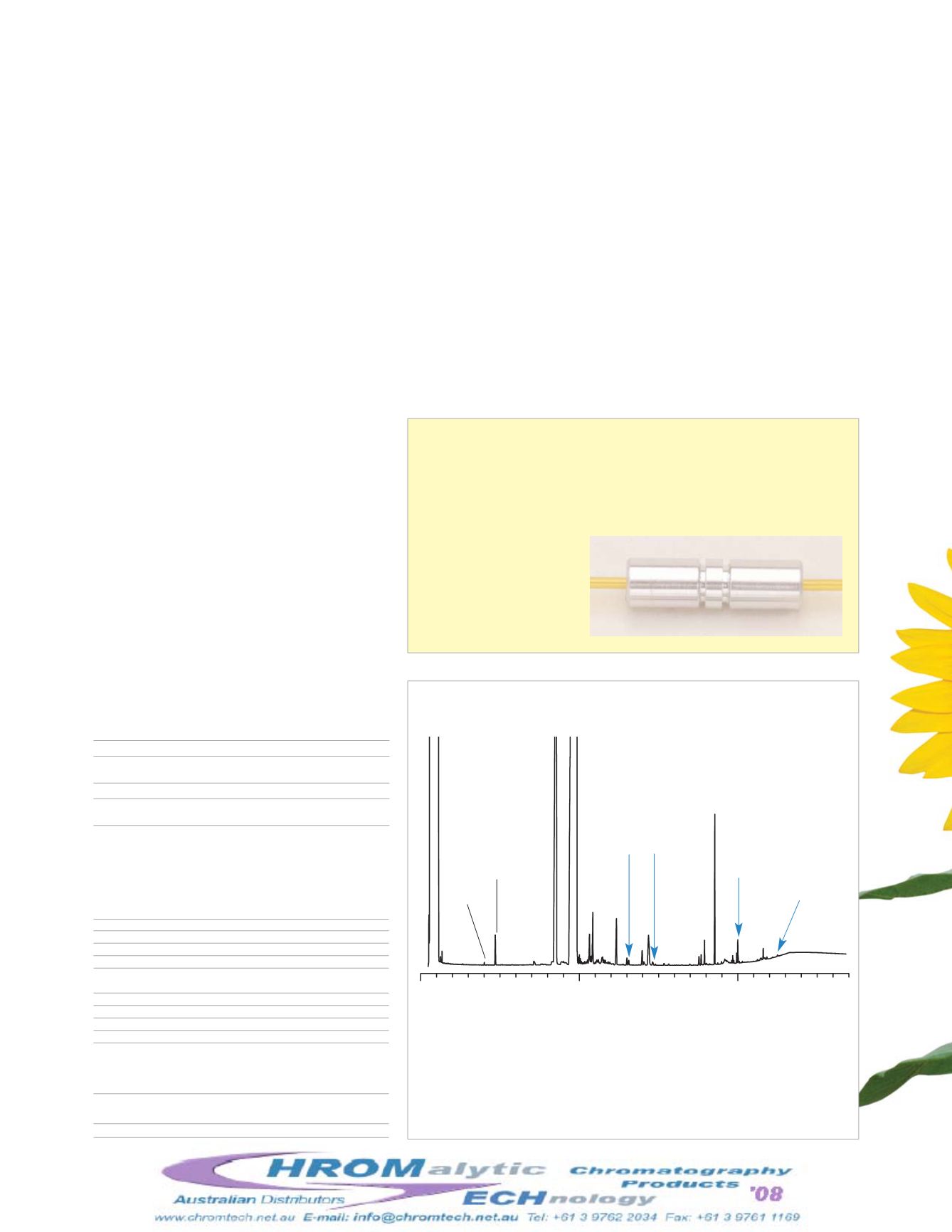

work.Thedata inFigure2 show the elutionof glycerin,monoglycerides,diglyc-

erides, and triglycerides inB100biodiesel followingASTMMethodD6584, uti-

lizing cool on-column injection.TheRtx®-Biodiesel TG columnprovides good

resolution and signal-to-noise ratios formono-, di-, and triglycerides.

Figure2

TheRtx®-Biodiesel TG columnmeets resolution criteria

and shows excellent response for determiningglycerin inbiodiesel.

0

10

20

Column:

Rtx

®

-BiodieselTG, 10m, 0.32mm ID, 0.10µm connected to 2m x 0.53mm

Hydroguard™ tubing using Alumaseal™ connector (cat.# 10291)

Sample:

biodiesel (B100) plusmonoolein, diolein, triolein, glycerin, butanetriol, tricaprin

Inj.:

1µL, cool on-column

Inj. temp.:

oven track

Carrier gas:

hydrogen, constant flow

Flow rate:

4mL/min.

Oven temp.:

50°C (hold 1min.) to 180°C@ 15°C/min. (hold 7min.) to

230°C@ 30°C/min. to 380°C@ 30°C/min. (hold 5min.)

Det.:

FID

Det. temp.:

380°C

glycerin

butanetriol (IS)

tricaprin (IS)

monoglycerides

diglycerides

triglycerides

GC_PC00890

Rtx®-BiodieselTGColumns (fusedsilica)

Rtx®-Biodiesel TGColumns:

• Low columnbleed at high temperatures.

• Alumaseal™ connector provides leak-free con-

nection, retention gap extends column life.

• Complete resolution for all compounds from

interference peaks.

Compound

CAS# cat.#

price

MSTFA (N-methyl-N-trimethylsilytrifluoroacetamide)

10-pk. (10x1g)

24589-78-4 35600

$65

25g FlexTube

24589-78-4 35601

$75

SilylationDerivatizationReagents

Compound

Solvent cat.#

price

(s)-(-)-1,2,4-butanetriol

1,000 33024

$33

(s)-(-)-1,2,4-butanetriol (5mL)

1,000 33032

$113

diolein(1,3-di[

cis

-octadecenoyl]glycerol)

5,000 33022

$31

glycerin

500 33020

$31

monolein

(1-mono[

cis

-9-octadecenoyl]-rac-glycerol)

5,000 33021

$31

monopalmitin

5,000 33026

$33

tricaprin (1,2,3-tricaprinoyl glycerol)

8,000 33025

$33

tricaprin (1,2,3-tricaprinoylglycerol) (5mL)

8,000 33033

$113

triolein (1,2,3-Tri[

cis

-octadecenoyl]glycerol)

5,000 33023

$31

BiodieselCalibrationStandards

Concentration is µg/mL in pyridine. Volume is 1mL/ampul unless

otherwise noted.

Figure1

: TheAlumaseal™connector

TheAlumaseal™ connector is the best column connector for coupling fused silica andmetal

columns, even columns of different internal diameters. Made of aluminum, it is designed for

high temperature performance.These connectors have been factory-coupled and tested using

temperature programmedmass spectrometry and have shown no signs of leaks, even at 430°C.

TheAlumaseal™ connector offers:

•A leak-tight connection.

•Low dead volume.

•Low thermal mass.

•High inertness.

Description

temp. limits cat.#

price

10m, 0.32mmID, 0.10

to 330/380°C 10292

$250

10m, 0.32mmID, 0.10w/2m x

0.53mm retention gap**

to 330/380°C 10291

$295

15m, 0.32mmID, 0.10

to 330/380°C 10294

$305

15m, 0.32mmID, 0.10w/2m x

0.53mm retention gap**

to 330/380°C 10293

$365

**Connectedwith low-dead-volume Alumaseal™ connector.

•

800-356-1688

2