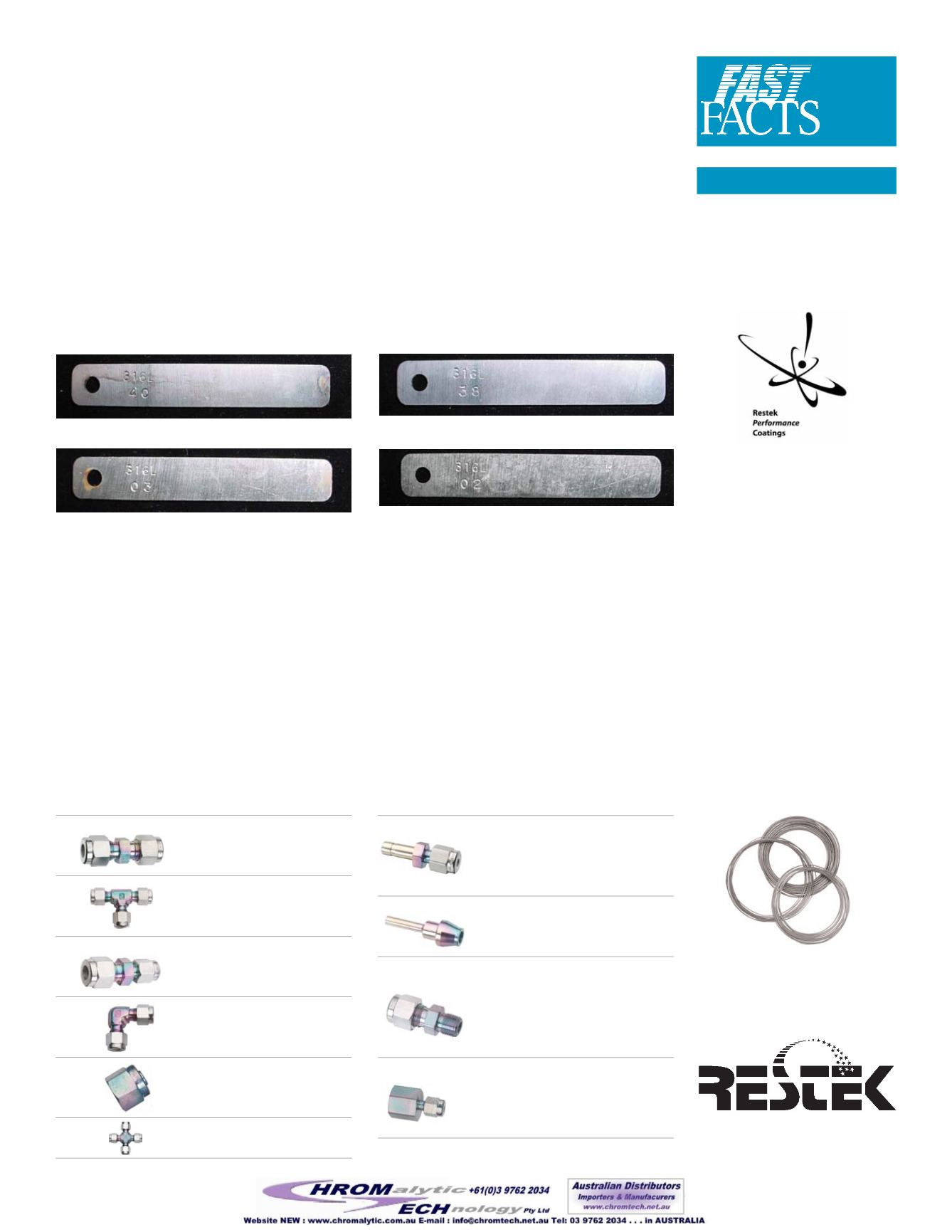

Figure4

Silcosteel®-CR treated316L stainless steel

coupons showno corrosionas a result of salt spray

testing; bare coupons show light rustingat aperature.*

Figure5

Silcosteel®-CR treated316L stainless steel

coupons showno impact ofwater exposure; bare

coupons exhibit a light oxide layer.

Silcosteel

®

-CR treated

Silcosteel

®

-CR treated

bare stainless steel

bare stainless steel

Silcosteel

®

-CRTreatedFittings

Abroad line of

1

/

16

",

1

/

8

" and

1

/

4

" fittings is availablewith Silcosteel®-CR treatment. Because of expanding appli-

cations for these coatings,wehave receivedmany requests for a broader product offering. If youdonot see

everything youneed, contact us for informationon additional stock items, or for custom coating services.

1000HourSaltSprayTesting (ASTMB117)andCondensingHumidityTesting (ASTMD4585)of

Silcosteel®-CRTreated316LStainlessSteelCouponsandBareCoupons

ASTMB117

(Practice ofOperating Salt Spray (Fog)Apparatus)

was run for a total of 1000hours.Three

Silcosteel®-CR treated316L stainless steel coupons and3bare couponswere tested side by side.The

Silcosteel®-CR treated coupons showedno signs of bleeding, rustingor pitting corrosion.The bare sam-

ples exhibited light surface rustingbut no signs of pitting. Figure 4 shows a Silcosteel®-CR treated sample

and a bare steel sample after salt spray testing.

ASTMD4585

(Practice forTesting theWaterResistance ofCoatings,UsingControlledCondensation)

was run for a total of 1000hours.Three Silcosteel®-CR treated316L stainless steel coupons and3bare

couponswere tested side by side.The Silcosteel®-CR treated coupons showedno signs of bleeding, rust-

ing, or pitting corrosion.The bare samples exhibited a very light surface oxide film as a result of expo-

sure. Figure 5 is aphotographof a Silcosteel®-CR treated sample and a bare steel sample after testing.

Description

Size

qty.

cat.#

Tube End Reducer

1

/

8

" tube to

1

/

16

"

ea.

22880

1

/

4

" tube to

1

/

16

"

ea.

22881

1

/

8

" tube to

1

/

4

"

ea.

22882

1

/

4

" tube to

1

/

8

"

ea.

22883

Port Connector

1

/

8

"

ea.

22884

1

/

4

"

ea.

22885

1

/

8

" to

1

/

4

"

ea.

22886

MaleNPTUnion

1

/

8

" to

1

/

8

"

ea.

22887

1

/

4

" to

1

/

4

"

ea.

22888

1

/

16

" to

1

/

8

"

ea.

22889

1

/

8

" to

1

/

4

"

ea.

22890

1

/

4

" to

1

/

8

"

ea.

22891

FemaleNPTUnion

1

/

8

" to

1

/

8

"

ea.

22892

1

/

4

" to

1

/

4

"

ea.

22893

1

/

4

" to

1

/

8

"

ea.

22894

1

/

8

" to

1

/

4

"

ea.

22895

Description

Size

qty.

cat.#

Union

1

/

16

"

ea.

22863

1

/

8

"

ea.

22864

1

/

4

"

ea.

22865

Tee

1

/

16

"

ea.

22866

1

/

8

"

ea.

22867

1

/

4

"

ea.

22868

Reducer

1

/

8

" to

1

/

16

"

ea.

22869

1

/

4

" to

1

/

16

"

ea.

22870

1

/

4

" to

1

/

8

"

ea.

22871

Elbow

1

/

16

"

ea.

22874

1

/

8

"

ea.

22875

1

/

4

"

ea.

22876

Plug

1

/

16

"

ea.

22877

1

/

8

"

ea.

22878

1

/

4

"

ea.

22879

Cross

1

/

8

"

ea.

22872

1

/

4

"

ea.

22873

Seepage4 for

Silcosteel®-CR treated

tubing.

At-a-Glance

Product

Information

fromRestek

Silcosteel

®

-CR

800-356-1688

★

814-353-1300

*Color at the tip of the Silcosteel

®

-CR treated coupon is due to light refraction by the treatment layer.

What advantages are gainedby applying Silcosteel®-CR treatment to steel and stainless steel compo-

nents in contact with corrosive environments? Silcosteel®-CR treatment will ensure longer lifetimes for

these components.Maintenance schedules canbe prolonged. Reduced corrosionwillmean less con-

tamination inprocess streams in contact with corroding steel substrates. Finally, Silcosteel®-CR treated

componentswill greatly reduce system cost, relative to super alloy components (e.g.,Hastelloy®or

Inconel®).

These fittings aremanufactured by

Parker Hannifin. Swagelok

®

fittings also are

available—see our website.