When surface activity or corrosion are a concern, solutions must be engineered. Restek Performance Coatings offers a family of sur-

face treatments that address reactivity and corrosion over a wide spectrum of applications. These treatments reduce process upsets,

reduce capital costs, and reduce maintenance costs.

Accurate sampling with Siltek®/Sulfinert®

tubing and fittings.

Adsorption problems in sample pathways often

can be traced to the tubing and fittings used to

transfer the sample to the analytical instrument.

Always use treated tubing and fittings for applica-

tions involving active compounds. To ensure max-

imum inertness and minimal surface area, use

Siltek®/Sulfinert® treated electropolished tubing.

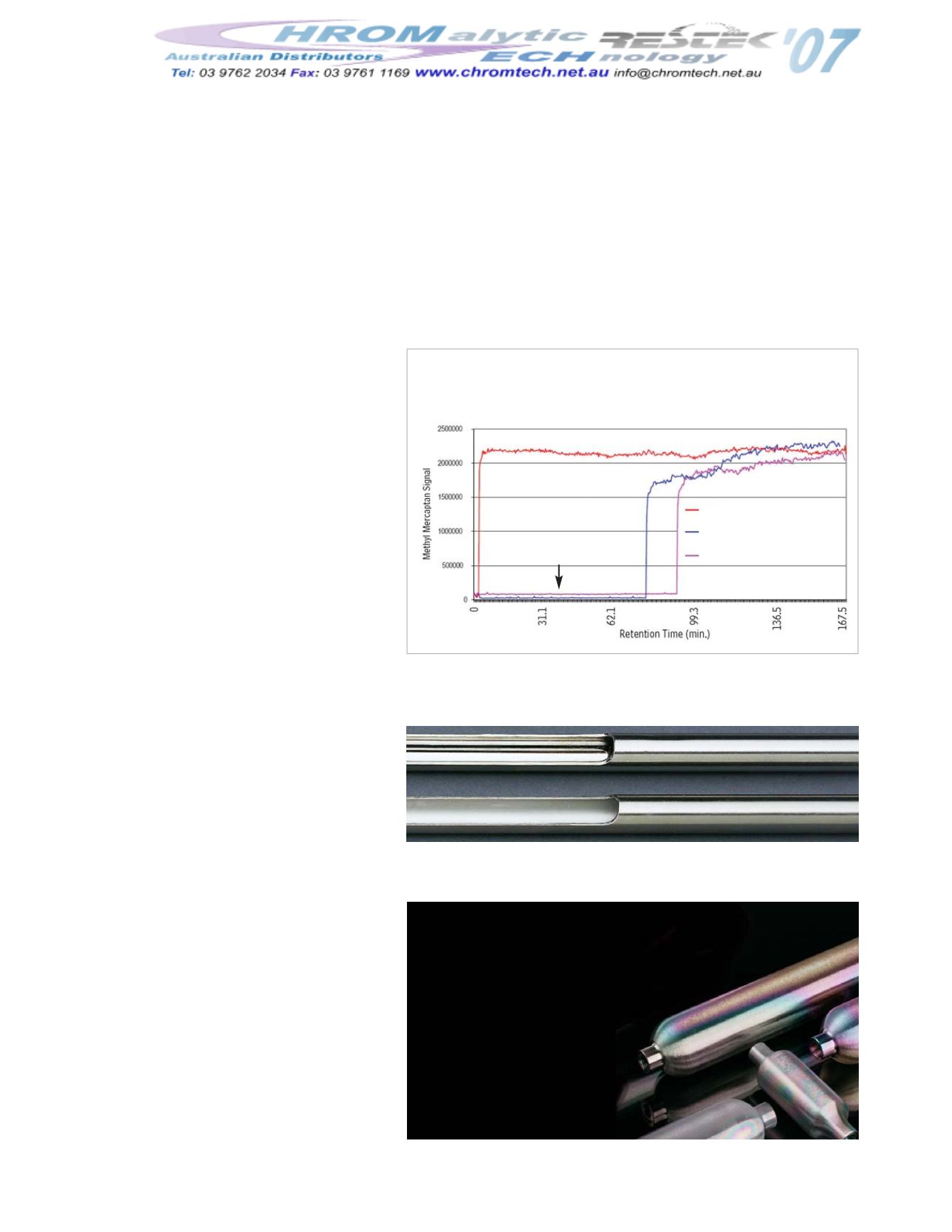

Figure 1 shows uptake and release curves for

500ppbv of methyl mercaptan, an active sulfur

compound, in a gas stream passing through a vari-

ety of tubing substrates. Siltek®/Sulfinert® treated

tubing reduces uptake by orders of magnitude, rel-

ative to untreated stainless steel tubing.

Reduce maintenance cost, extend system life

with Silcosteel®-CR tubing and fittings.

In corrosive environments, Silcosteel

®

-CR treatment

is an excellent alternative to expensive alloys.

Silcosteel

®

-CR treatment extends component life

while reducing the frequency of preventive main-

tenance and ensuring the purity of the process or

sample stream. Silcosteel

®

-CR improves corrosion

resistance by up to 10X over untreated 316 stainless

steel (Figure 2).

Figure 3 shows the results of a 4000-hour salt spray

test on Silcosteel

®

-CR treated 316L stainless steel

and untreated 316L stainless steel. The Silcosteel

®

-

CR treated material exhibited virtually no change.

Silcosteel

®

-CR treatment has extended the life of

process systems in oil and gas production, oil

refining, petrochemical processing, aerospace

equipment, food and beverage processing, and

laboratory testing. Figure 4 shows Silcosteel

®

-CR

treatment can reduce the overall lifetime cost of a

typical process system by hundreds of thousands

of dollars. While the initial cost of an unprotected

stainless steel system is lower than that of a com-

parable Silcosteel

®

-CR system, the overall lifetime

cost, considering replacement cost due to corro-

sion, is nearly double that of a Silcosteel

®

-CR treated

system. High performance alloy systems offer

superlative corrosion performance, but the initial

material cost can be up to six times that of a stain-

less steel system.

Figure 1

Sulfinert® treated electropolished seamless stainless

steel tubing does not adsorb methyl mercaptan (500ppbv).

•

16

•

2007 vol. 2

Restek Performance Coatings

Assure Accurate Sampling and Reliable Sample Purity

Restek Sampling System Treatments Prevent Adsorption, Protect Components

By Gary Barone, Manager, Restek Performance Coatings

• Quantify active compounds (e.g., sulfur, mercury, NOx) at parts-per-billion levels.

• Corrosion protection equal to specialty alloys – at lower cost.

• Assemble a new system from treated stock, or treat an existing system.

methyl

mercaptan

adsorbed

simply

the best

Restek-treated electropolished tubing is the best tubing choice when purity, inertness, or

reproducibility are concerns.

Top: electropolished finish, surface roughness average number: 5-10. Bottom: conventional finish, surface

roughness average number: 23-27.

Sulfinert® treated electropolished

untreated electropolished

uncleaned

Get More!

Restek Performance Coating

Related Articles Online

“Protect Sample Integrity

and Prolong Sampling

System Lifetime”

www.restek.com/coatings