• 8 •

www.restekcorp.comby Neil Mosesman, GC Columns Product Marketing Manager

Column Bleed &

System Contamination

Identifying and Reducing Sources of Rising

Baselines in GC Analysis

Rising baselines are a common occurrence during

temperature-programmed gas chromatography (GC)

(Figure 1). The rise in the baseline can be caused

by several factors: stationary phase bleed from the

analytical column, contamination in the injection or

detection system, and/or a change in the flow rate.

The magnitude of the baseline rise often depends on

the sensitivity of the detection system. With very sen-

sitive detectors, even a small amount of bleed or

contamination can cause a significant rise in the

baseline. Reducing or eliminating rising baselines

can improve qualitative and quantitative reliability of

your chromatographic analyses.

Because both the column and the system can con-

tribute to rising baselines, it is important to distin-

guish between the two sources when troubleshoot-

ing. The simplest way to do this is to remove the

analytical column from the system, cap off the detec-

tor, and determine the background level during a

temperature-programmed run. If the baseline is

unstable, follow the recommendations in “How can

detector effects be reduced?” If the baseline is sta-

ble, connect a jumper (i.e., a short length of clean,

uncoated fused silica tubing) from the injector to

the detector and perform another temperature-

programmed run to show the effects of the injector

on baseline stability. If the baseline is unstable,

follow the recommendations in “How can injector

effects be reduced?” If the baseline from the injector

and detector is stable, install the analytical column

and perform a temperature-programmed run with-

out making an injection to determine if addition of

the column increases the background level.

How can injector effects be reduced?

Injector contamination can be a major cause of

baseline instability. High molecular weight, non-

volatile residue from the sample can slowly migrate

through the analytical column and cause a rise in

the baseline during a temperature-programmed

run. It often is difficult to determine if the baseline

rise is caused by the column or by injector contam-

ination. Removing the column from the GC and

running a jumper (see above) will isolate the

source of the baseline rise. If the injector is con-

tributing to the bleed level, maintenance should be

performed. In particular, replace the septum, liner,

and seal. In cases of extreme contamination, rins-

ing the injection port with solvent may be necessary.

After maintenance, confirm the cleanliness of the

injection port by performing a blank injection with

the jumper installed between the injector and the

detector.

How can detector effects be reduced?

Baseline rise from the detector is usually caused by

contamination or impure gas. Proper detector main-

tenance, including periodic cleaning, is critical to

minimizing baseline rise. Make-up gas and/or fuel

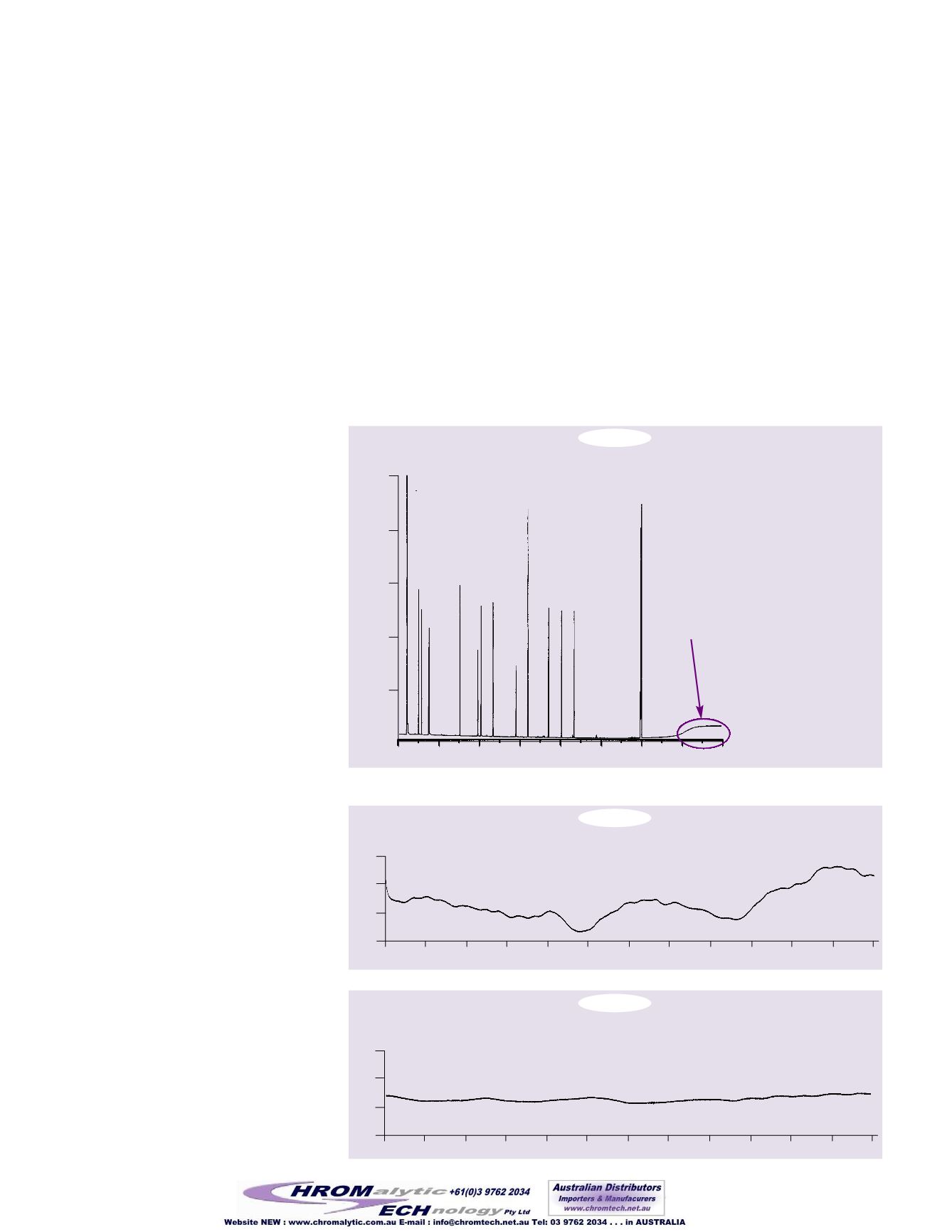

gases also can contribute to bleed. Figure 2 shows

an unstable flame ionization detector (FID) baseline

caused by trace impurities in the compressed air

supply to the flame. Switching to a high-purity air

generator that employs traps to remove trace hydro-

carbons can greatly improve FID baseline stability

(Figure 3). Using high-quality gas purifiers for make-

up gas and fuel gases is critical to reducing back-

ground levels caused by the detection system.

How can column bleed be reduced?

If the baseline rise caused by the injector and

detector has been reduced and the baseline still

remains high, then the most likely cause is column

bleed. The magnitude of column bleed is related to

the final oven temperature. Higher final tempera-

Figure 1

Rising baselines are a common occurrence during temperature-programmed GC.

Figure 2

Trace impurities in the carrier gas can cause an unstable FID baseline.

Figure 3

Using a high-purity gas generator and traps to remove contaminants can greatly improve

FID baseline stability.

bleed

GC_EX00388

✔

Improve qualitative and

quantitative reliability

✔

Increase column lifetime

0 min.

100

200

300

400

500

600

6

4

2

picoamps

0 min.

100

200

300

400

500

600

6

4

2

picoamps

0 min. 5

10

15

20

25

30

40

34

30m, 0.25mm ID, 0.25µm XTI

®

-5

(cat.# 12223) XTI

®

test mix

injection;

Oven temp.:

100°C to

300°C @ 6°C/min. to 360°C @

15°C/min.

100

80

60

40

20

picoamps

GC_EX00390

GC_EX00391