•

3

•

2005 vol. 2

The United States Environmental Protection

Agency (US EPA) is actively developing regula-

tions, limits, and control measures for monitoring

and controlling mercury emissions from coal-fired

power generators—one of the major sources of

mercury emissions into the environment.¹ As these

regulations and guidelines are developed and

implemented, proper equipment will be needed

for accurate sampling and analysis. Testing costs

for mercury can be substantial (Table 1)², so inac-

curate analyses can have financial as well as envi-

ronmental repercussions.

In flue streams from coal-fired power generators,

mercury exists in three forms: elemental, the +2

oxidation state (Hg

++

), and attached to particulate

matter. Hg

++

often reacts with sulfur compounds,

nitrogen, chlorine, and/or oxygen, to produce sul-

furous, nitrous, chloride, and oxide mercury

species. Elemental and oxidized mercury can easily be lost to reactions and

adsorption on the inner surfaces of monitoring equipment. In order to accu-

rately sample and quantify mercury in all forms, it is important to use inert

sample pathways. Laboratory testing and field results have proven that

Sulfinert® treated sampling and testing equipment is essentially inert to active

molecules³, including mercury.

Siltek®/Sulfinert® treatment can be applied to many of the components in a

mercury sampling stream, including probe tubing, impingers, fittings, filters,

housings, and transfer tubing (Figure 1). Treating all of the components of a

stack or continuous emission monitoring system will greatly improve analyt-

ical reliability and sensitivity, which will be needed as regulations are brought

on line and emission quotas are enforced. Fast and accurate testing, without

re-work, can save a great deal of time and money.

Similarly, a Siltek®/Sulfinert® treated sampling system will improve the relia-

bility of data for sulfurous oxides and nitrous oxides (SO

x

and NO

x

). As with

mercury, it is difficult to reliably transfer these compounds through untreated

sampling equipment.

In addition to preventing adsorption of reactive compounds,

Siltek®/Sulfinert® treatment will act as a barrier, protecting and prolonging

the lifetime of treated equipment. The durable layer will withstand tempera-

tures to 400°C.

We offer Siltek®/Sulfinert® treated tubing, sample cylinders, and other com-

ponents from stock; to discuss custom treatment of system components,

please contact the Restek Performance Coatings team.

Accurately Monitor Mercury-Sulfur-Nitrogen Compounds

Siltek®/Sulfinert® Treatment Prevents Adsorption of Mercury, Sulfur Oxides,

or Nitrous Oxides in Emission Monitoring Equipment

By Gary Barone, Restek Performance Coatings Division Manager, David Smith, RPC Chief Scientist, and Martin Higgins, RPC Chief Engineer

• Improved analytical reliability and sensitivity for mercury, SO

x

, or NO

x

compounds.

• Protection from corrosion—longer component lifetime.

• Apply to new or existing equipment.

Table I

Typical costs of mercury sampling (U.S.).²

Method

Approx. Cost of Analysis

US EPA 29

$300

US EPA 101A

$100

ASTM D6784-02

$250

US EPA 324

$430

FAMS

$640

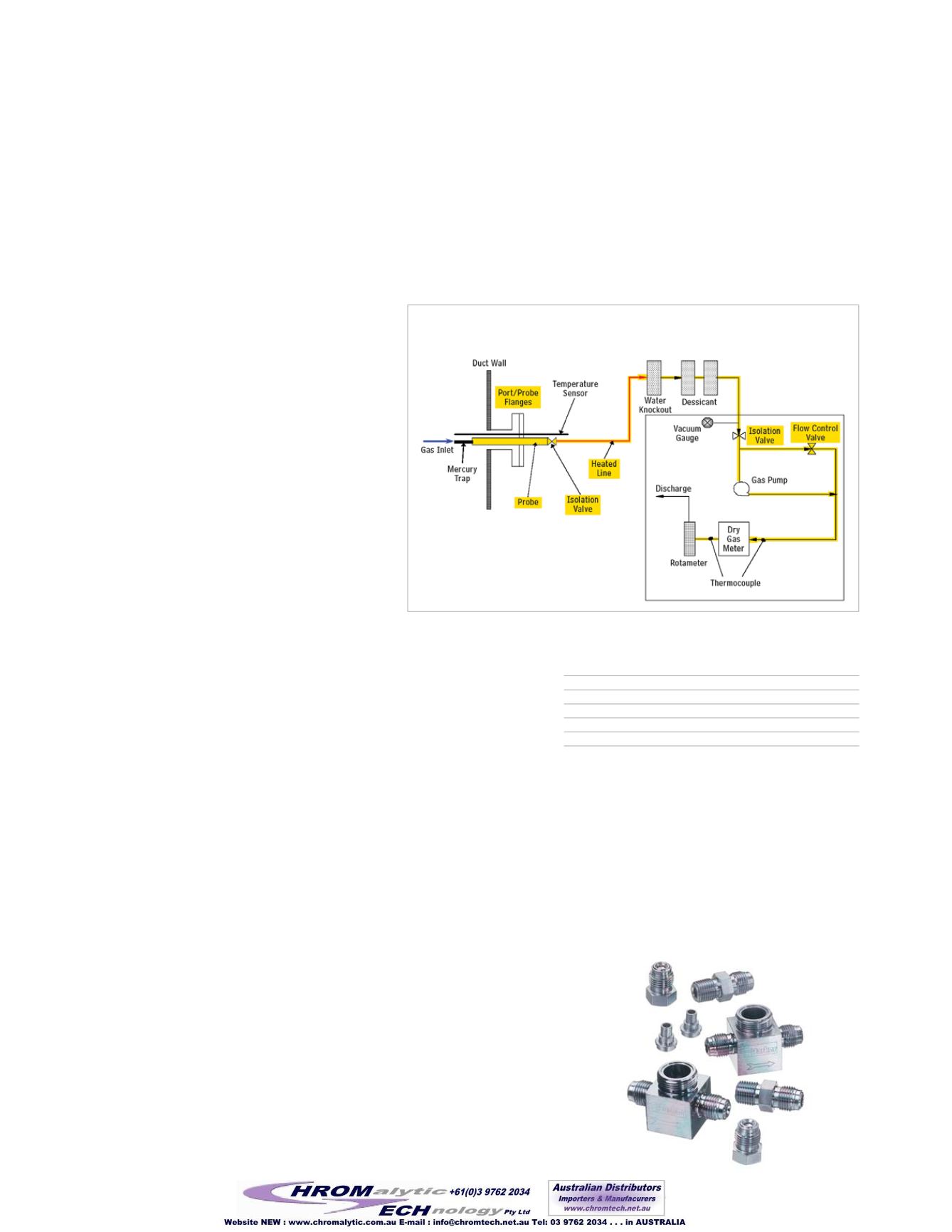

Figure 1

Highlighted components of a mercury sampling train,

4

and all tubing in the system, can be Siltek®/Sulfinert® treated.

Restek offers treated and untreated tubing, fittings, and valves, passive air sampling kits, air sampling canisters

and miniature air canisters, sample loops, and more. For more information, request our catalog or visit us

online.

www.restekcoatings.comReferences

1. Pottinger, M., S. Stecklow, and J.J. Fialka,

Invisible Export, A Hidden

Cost of China’s Growth: Mercury Migration

The Wall Street Journal

Online, Dec. 17, 2004.

2. Serne, J.C.,

An Overview and Comparison of Available Mercury

Emission Test Methods for Boilers

Symposium on Air Quality

Measurement; Methods and Technology 2005, San Francisco, CA; Air

& Waste Management Association. paper no. 439, pg. 9.

3. Barone, G., M. Higgins, D. Smith, S. Rowan, W.J. Gross, and P. Harris,

The Surface for Sulfurs

Hydrocarbon Engineering, Dec. 2004, pp 47-

50.

4. Proposed Method 324.

Determination of Vapor Phase Flue Gas

Mercury Emissions from Stationary Sources Using Dry Sorbent Trap

Sampling

United States Environmental Protection Agency. Washington,

D.C. p. 5.