722

W

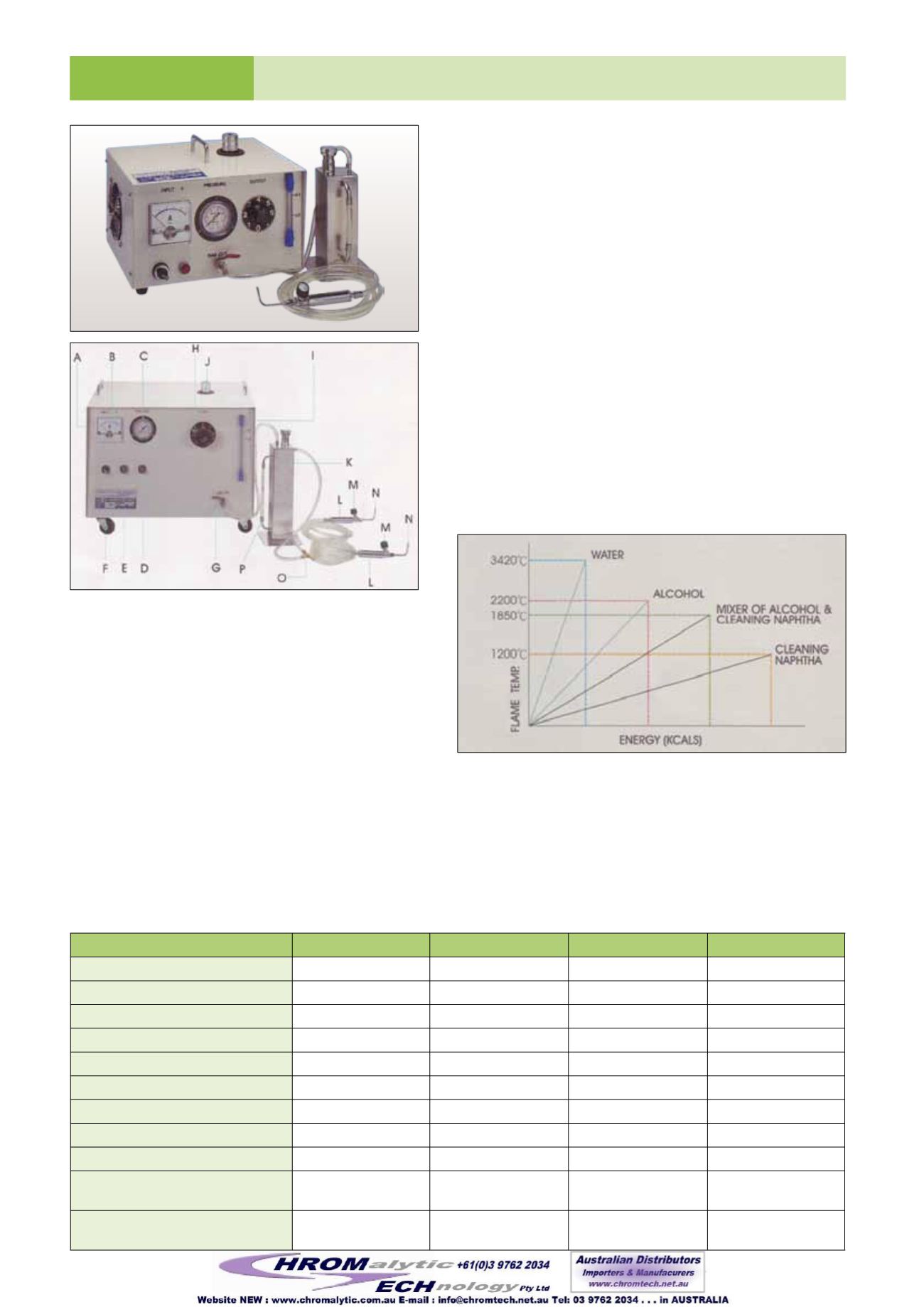

High Temperature Flame Water Welder

Just add di-water & plug the plug. Then you can get the

mixed gas of hydrogen & oxygen which pass through the

fan to condense water vapor. The functions of booster are

to add the enthalpy, to reduce the flame temperature, to

rise the pressure of gas and to increase the energy. It's a

very economical method to have a hi-temperature flame.

Features:

●

Fuel are water, electric power & a little of solvent.

Easy to get and storage safety.

●

2h2+o2 burn 2h2o (vapor). the vapor left from burning is

non toxic and non pollution.

●

Good designed machine constructor, for continuous

operation.

●

Torch with built-in diffusion stone, pressure switch,

over-pressure relieve valve, to protect the machine

absolutely safety.

●

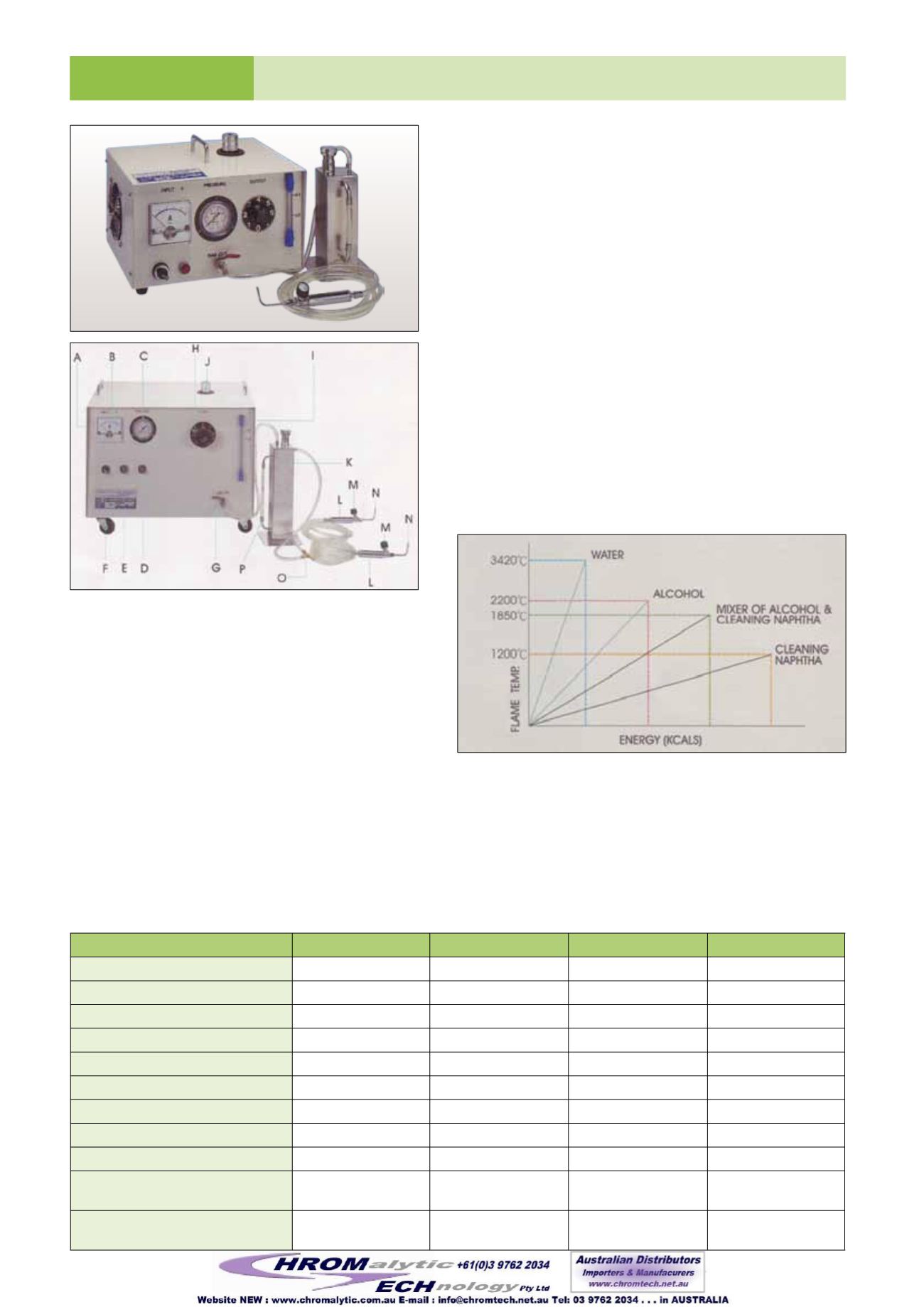

Flame temperature range is up to 3420°C or can be

down to 1200°C.

●

Easy to change the flame size especially in very fine

flame usage area. Tip orifice size are from 0.076mm

<t(30#) to 1.056mmct (16#).

●

Compact and easy operation.

FWW-270

Model

FWW-270

FWW-640

FWW-1200

FWW-1600

Max. KCAL Output

270 Kcal/hr

430 Kcal/hr

800 Kcal/hr

1600 Kcal/hr

Max. Power Input

400 watts

640 watts

1200 watts

2400 watts

Max. Torch Tip Orifice

No.21

No.20

No.19

No.18

Electrolyte Capacity

1.6e

3e

6e

10e

Dl Water Consumption Rate

0.02e/hr

0.035e/hr

0.06e/hr

0.12e/hr

Dl Water Addition Interval

8hr

8hr

8hr

8hr

Power

110/220V 50/60 Hz 1¢ 110/220V 50/60 Hz 1¢ 110/220V 50/60 Hz 1¢ 110/220V 50/60 Hz 1¢

Packing Dimension(mm)

W370xD370xH340 W510xD410xH400 W580xD500xH560 W680xD540xH560

(N.W)

24kgs

34kgs

55kgs

67kgs

Solvent Consumption Rate

(BOOSTER)

0.005e/hr

0.009e/hr

0.015e/hr

0.03e/hr

NO. Of Simultaneous

Operation Torch With # 21 Tip

1

2

4

6

Applications:

●

Metal welding: lead-tin soldering, gold, silver,

copper, brass brazing, for spot & plate welding,

such as ear-ring, necklace, chains, finger ring, etc.

●

Glass process: ampoule sealing, quartz glass

process, mercury switch sealing, glass capillary tube

forming, bending, etc.

●

Motor industry: stator copper-thread welding and

no need to peel the cover.

Booster’s Function Diagram

A. Cooling fan

B. Input a meter

C. Gas pressure gauge

D. Tank hi pressure cut

off pilot

E. Power on pilot

F. Power switch

G. Gas out valve

H. Output adj.

I. Electrolyte tank sight

glass

J. Di water add port

K. Booster

L. Diffusion stone pipe

M. Flame adj. valve

N. Torch tip

O. Three way connection

P. Booster sight glass

●

Hi-melting point metal welding: thermal couple thread

welding, led plate connecting, computer stripping

teflon tape cable cover peeling and cutting. gold wire

ball bonding.

●

Sun glasses hinge’s welding.

●

Acrylic surface or edge flame polishing.

●

Tooth mold pin hole mending.

●

Lead acid battery electrode plate welding.

●

Heat treatment for small part and precise craft.

FWW-Series, High Temp. Flame Water Welders

WELDERS