- 4 -

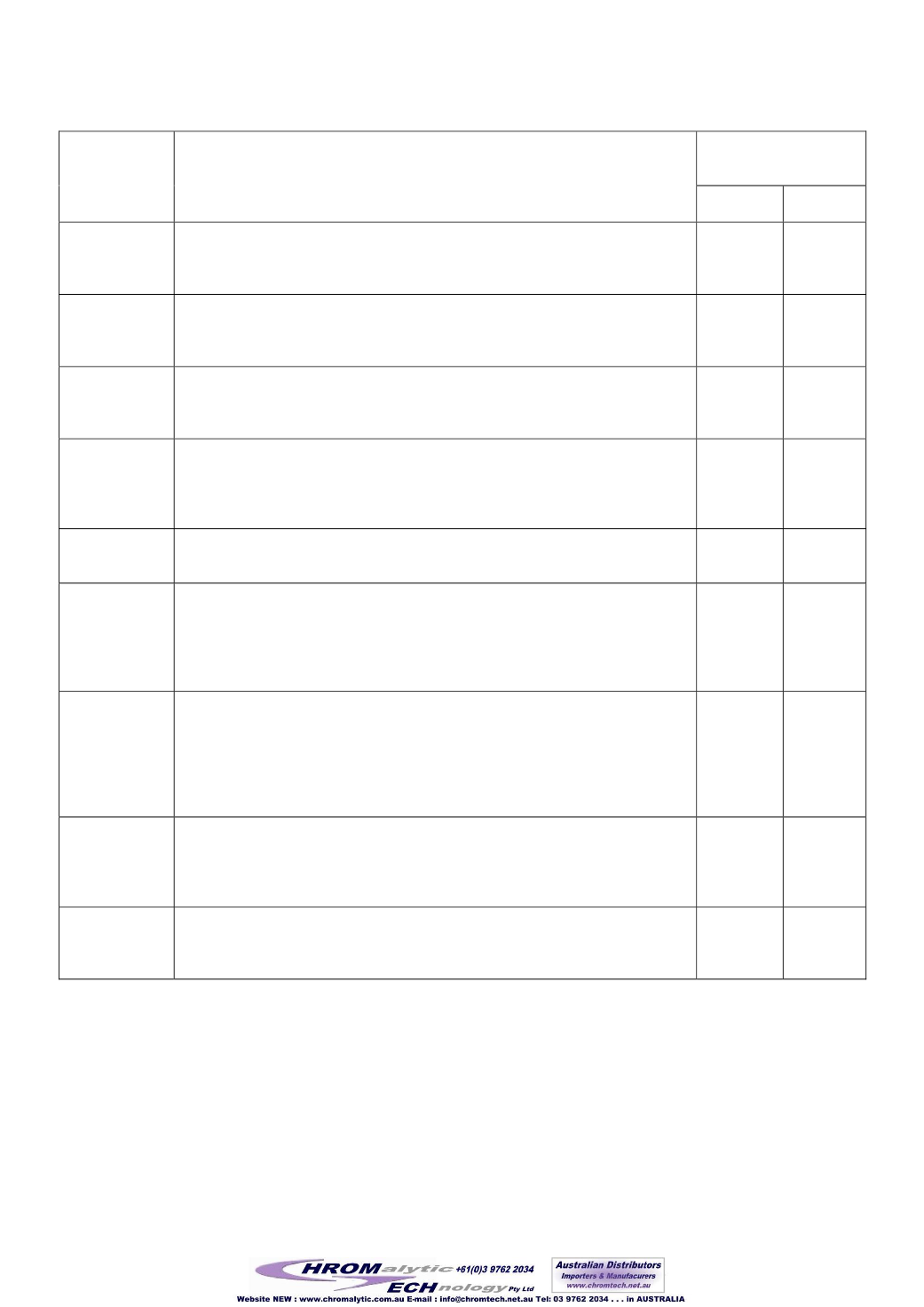

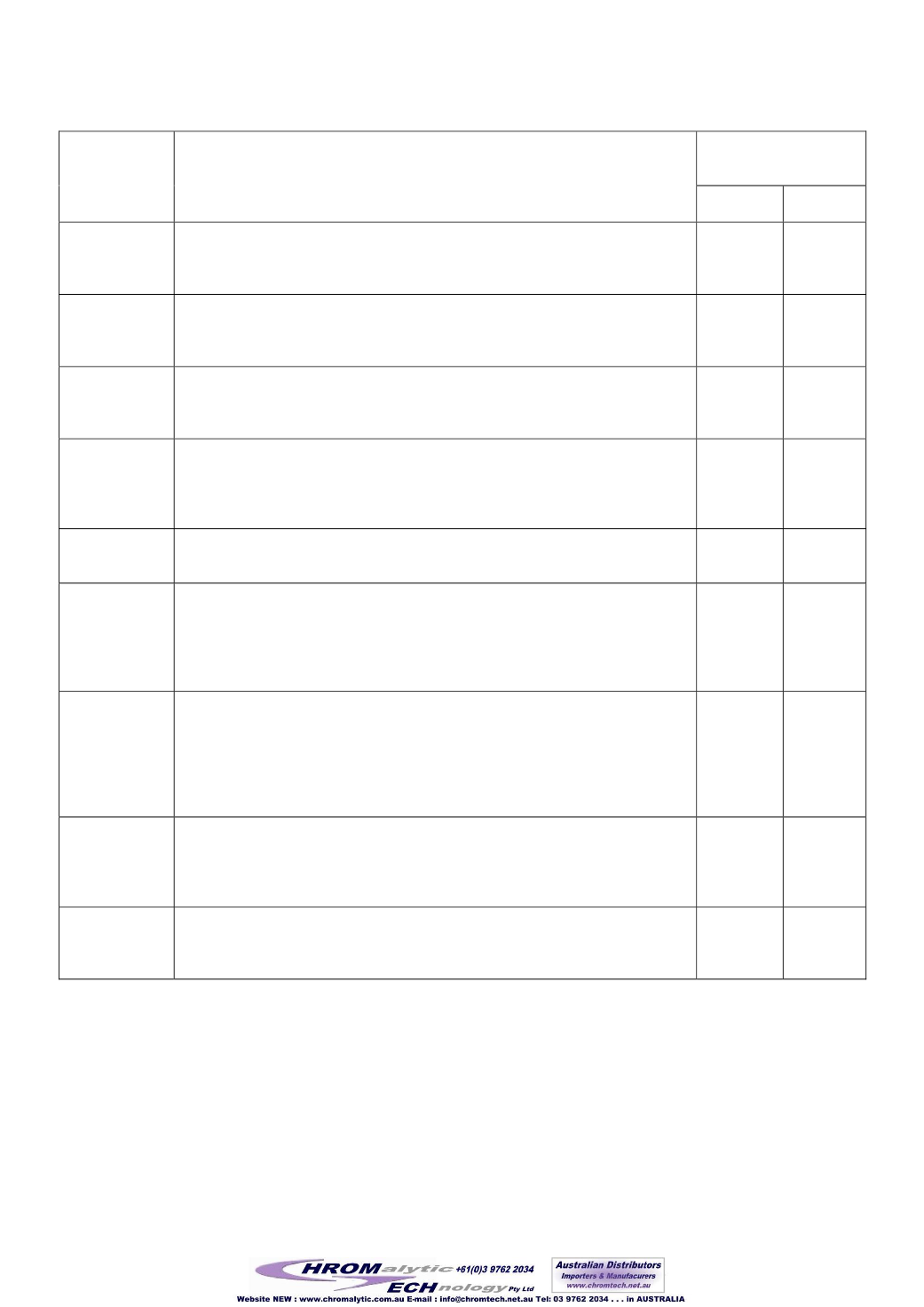

Comparison of functional features of different types of mechanisms

Parameter

description

Assessment of

Construction against

traditional mechanism

monoblock

compact

system

Statistic

weighing errors

(hysteresis,

linearity)

Due to higher durability parameters of elastic bearing elements (flexures) for

correctly assembled traditional mechanism it is possible to reach lower errors

than in monoblocks

-

+/-

Temperature

errors (static

and dynamic)

Statistic temperature errors are fully compensated by electronic units and cannot

me omitted. Dynamic errors depend on correctness of specific mechanical and

electronic constructions and their size cannot be only associated with the type of

traditional mechanism, monoblock or compact system.

+/-

+/-

Weighing time

Weighing time depends mostly on electronic solutions applied. For

electromagnetic balances, weighing time depends, to a small degree, on the mass

of weighing elements, which does not move while weighing, which results from

work principle of mass determination system applied.

+/-

+/-

Resistance

against

transport

shocks and

overloads

Theoretically, better durability of flexures should favour balances with

traditional mechanism extended and commonly used in all made mechanisms

additional protecting elements determine the durability of the specific balance

against shocks and transport.

+/-

+/-

Labour

intensity of

assembly

Due to quantity of parts and the necessity to mount them with high precision,

assembly time of monoblock is the shortest, assembly time of traditional

mechanism is the longest and assembly time of compact system is medium.

+

+/-

Labour

intensity of

manufacturing

parts

Generally the cost of manufacturing monoblock in comparison with traditional

mechanism is very high due to very high costs of operating expensive machine

tools for metal processing.

In compact systems in comparison with monoblocks, high precision machining

is applied to a small number of elements, and the body unit of mechanism is

made as aluminium casting where only insignificant part is machined.

-

+/-

Production

costs of

mechanism

Production cost is the sum of manufacturing costs and assembly costs. With high

costs of hand-made materials, in the older countries of UE, it is justified to

replace it with machine made materials.

However, in the final estimate, the production of compact solution, being a

compromise, which guarantees high quality of balances and with Polish wages

costs is the most beneficial. It is confirmed by the prices of balances offered in

the market.

+/-

+/-

Servicing

Servicing costs of mechanical elements are definitely the lowest for compact

systems. Replacing rocker sets is fast, does not require special instruments and

does not trigger the necessity of correcting temperature parameters.

In the case of monoblocks the whole damaged monoblock needs to be replaced

which is easy for the service but very expensive for the end customer.

-

+

Material wear

and energy

consumption

(ecology)

During production process of monoblocks, especially the older versions, there

are more output materials processed through machining and with newer versions

there is more energy consumed for machining than in the case of shape cut out

using a string.

-

+

186