INFRARED

Cameras

Model

IR-CAM-EX330

Detector Data

Detector type

Uncooled FPA

IR resolution

384 x 288 pixels

Pixel pitch

25μm

Spectral Range

8 ~ 14um

FOV/Mini Focus

18°×14°/0.15m

IFOV

1.2 mrad (standard lens)

NETD/Sensitivity

<65mk@30ºC

Image Performance

Frequency

50/60Hz

Focus

Manual

Digital Zoom

2×

Image Display

Built-in 3.5” color LCD

Measurement

Temperature range

-20ºC ~ 310ºC

Accuracy

±2ºC or ±2% of reading

Measurement spot

4 adjustable spots

Measurement area

3 adjustable boxes, capture

max./min./ avg. temperature

automatically

Line Measure

Vertical/horizontal

Isotherms Analysis

Detect high/low

temperature/interval

Alarm

Voice, color

Emissivity correction

Adjustable from 0.01 to 1.0

Multiple Language

Menu

10 Languages (English, French,

Italian, German, Spanish,

Portuguese, Russian, Korean,

Japanese, Simplified Chinese

& Traditional Chinese)

Model

IR-CAM-EX330

Image Storage

Storage type

Built-in flash card,

up to 1500 images

Files format

Standard JPEG, 14-bit measurement

data included

Voice comments

40s voice record, stored with per

image via built-in microphone.

Laser Type

Class 2, 1mW/635nm Red

Power System

Battery type

Rechargeable and explosion-proof

Li-ion battery

Battery operating time

Approx 1.5 hours at room

temperature

Power saving

User defined

Power operation

12V ±5%

Environment Data

Operating temp. range

-20ºC - +50ºC

Storage temp. range

-40ºC - +60ºC

Humidity

≤

95% non-condensing (+25ºC)

Shock

30G MT210-1990

Vibration

2G MT210-1990

Physical Data

Size (LxWxH) (mm)

330x95x86

Weight

650g

Tripod mounting

1/4”-20

Interfaces

External DC input

Yes

Audio output

Yes

Video output

PAL / NTSC

USB

Images transfer to PC

Packing Includes

Standard

Thermal imaging camera with

standard IR lens, 2 Li-ion batteries,

Battery charger, Adapter(only used

above the mine), Video cable USB

cable, Software CD, instruction,

warranty card, transport case

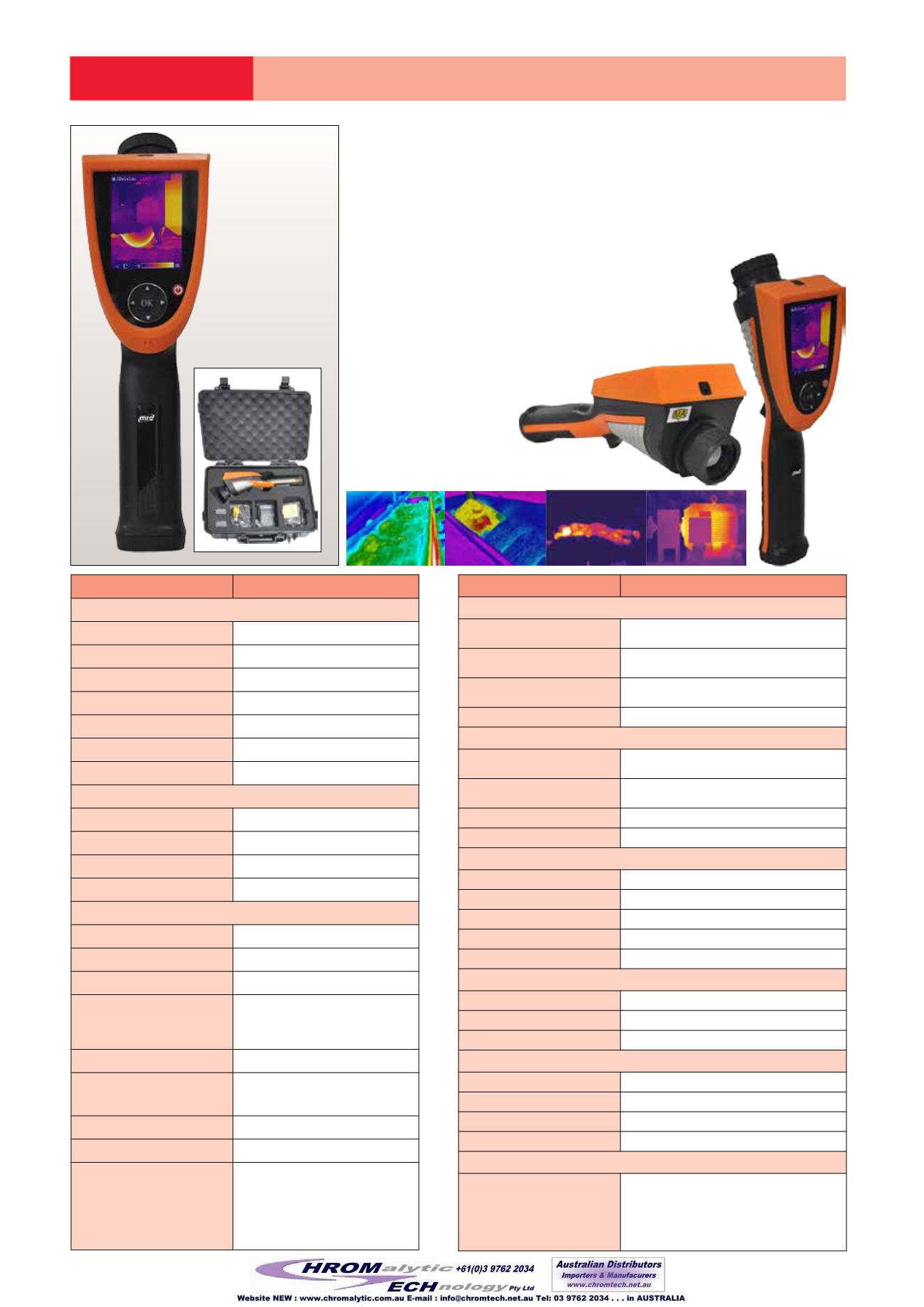

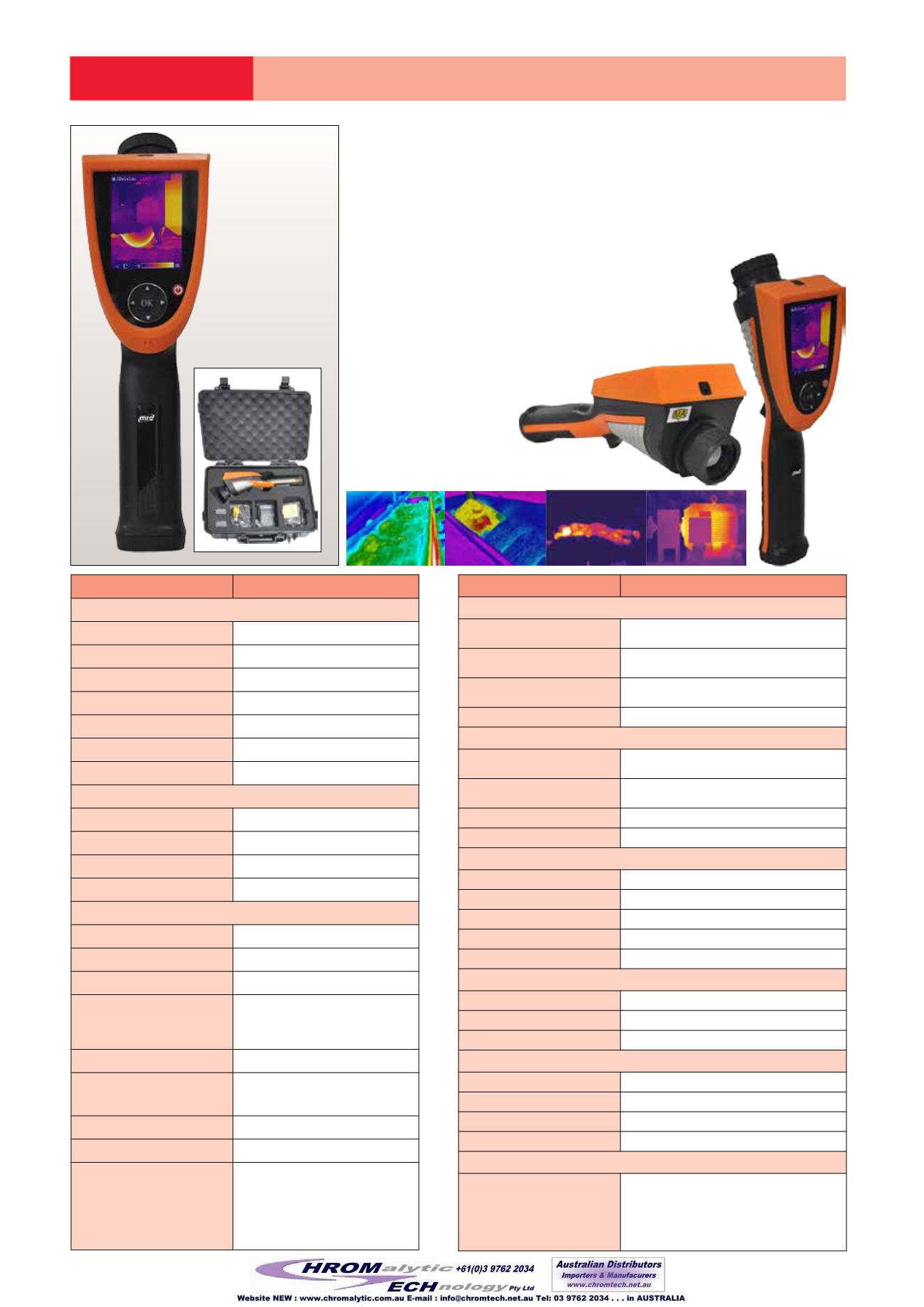

IR-CAM-EX330, Hazardous Thermal Imaging Camera

IR-CAM-EX330

Thermal imaging cameras IR-CAM-EX330 is certified intrinsically safe and

specialized for oil/gas, mining industry and other hazardous(explosive) areas

applications. It’s the ideal device for maintenance inspections of checking

refractory lining in crackers and heaters, missing or damaged pipe insulation,

steam traps, motors, bearings, gearboxes, shaft misalignment, trace heating,

flares, tank levels, condenserfins, heat exchangers, pumps,

pipe and valve leakage, poor lubrication.

Features:

●

Heat-resistant, shock-proof housing

●

Bright and clear 3.5” display to observe hot spots easily

●

Voice annotation, mark information instantly

●

Automatic high spot recognition, find hidden defects in time

●

Voice and color alarm

●

Laser pointer, assists user to locate

target easily

●

Rugged & compact

design

●

Certified by national

authority testing organization.

MRC.6.14

180