VALVES

127

EffectsofValvesand

TubingonResolution

The effect of tubing on analytical andmicroscale analyses can be

significant. Sincedispersion causedby tubing is proportional to the

fourthpowerofdiameter, largebore tubingshouldbeavoidedwhen

performing analytical scale or microscale analyses. Tubing ID size

≤0.25mm (0.010”) is recommended.

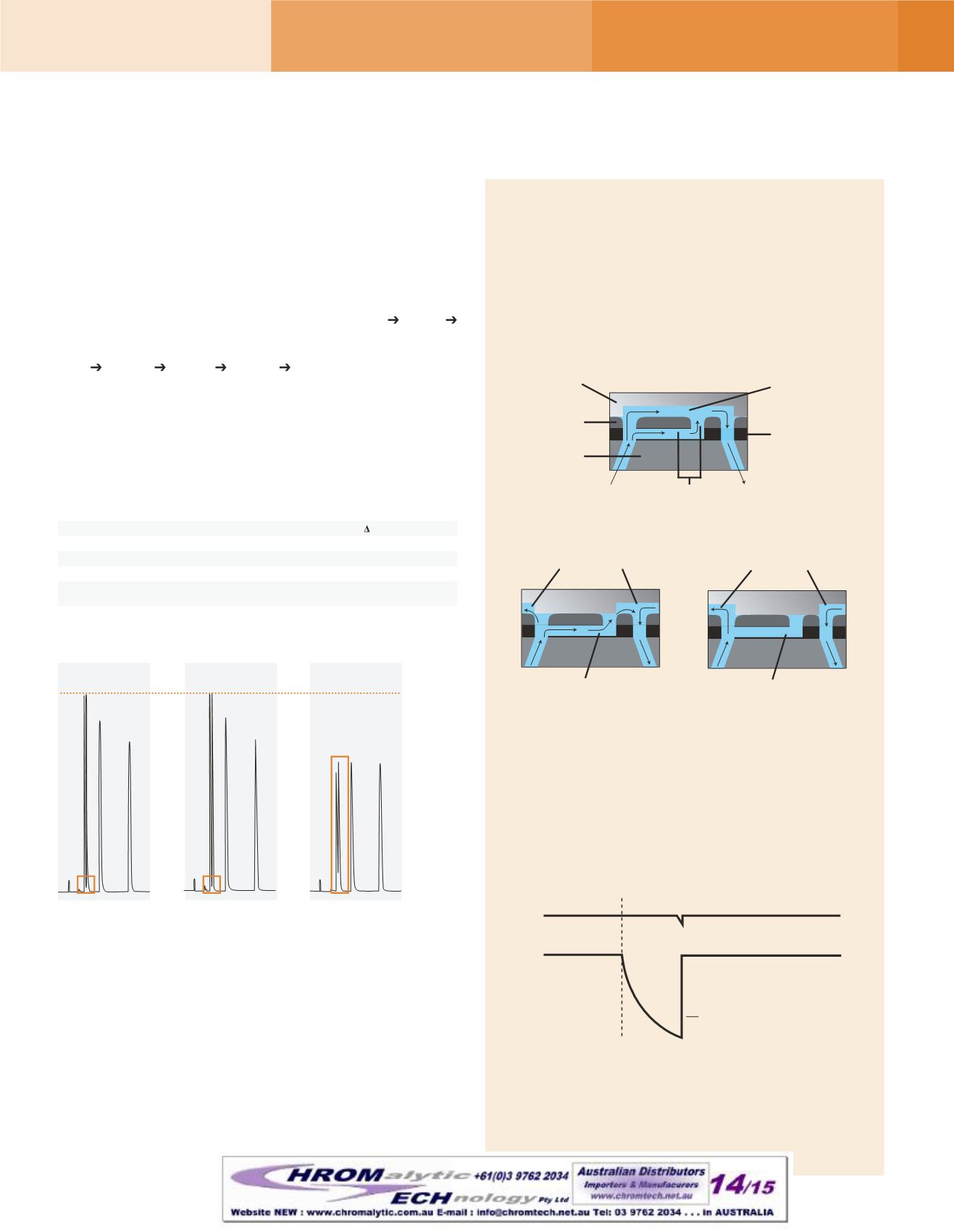

Consider a system with injection and column switching valves

and analytical columns with small-bore connecting tubing. The

chromatogramsbelow,madeusingatypicalanalyticalchromatograph,

showtheseeffects.SchemeA isthecontrol (injectionvalve column

detector)withnovalve in thesystem. InSchemesBandC, twomodel

7060Six-PositionSwitchingValveswereplacedsidebyside (injection

valve valve#1 column valve#2 detector).

The injection valve anddetector were connected to these valves by

thesame tubingused in thecontrol.Theextra tubingpieces required

to connect the valves to the columnwere a 10 cm length for valve

#1-to-column,anda35cm lengthforcolumn-to-valve#2.Thediameters

of these tubes are indicated in theexperimental details, below.

ComparisonofObservedColumnPlatesof Rheodyne

®

Analytical andMicroScale InjectionValves

Effectsof Valves andTubingonResolution

Conclusion: These sequential chromatograms show the effect of

addingvolume to theflowpath through theadditionof components.

(A) Establishes a baseline quality of separationwith theminimum

volumeof liquid in theflowpath.

(B)Addinga valveplus smaller-ID tubing, and thereby increasing the

liquidvolumeonlymarginally,barelyaffectstheseparation.However in

(C)Addingavalveplus larger-ID tubing, thereby increasing the liquid

volume in the flowpath to a greater degree, distinctly impairs the

qualityof the separationand thedetectable sample.

7725

8125

k’ = 0.6

2930

5054

72%

k’ =1.5

4653

6904

48%

k’ = 7.9

7875

8305

5.0%

UVdetector: 1µLvolume, 4mmpath. Samplevolume: 2µL, partial-fillingmethod.

Column: 2mm IDx100mm long, 4µmC-18. Trueplatesof column=11,570.

What isMake-Before-Break

™

,

andWhenDoes itMatter?

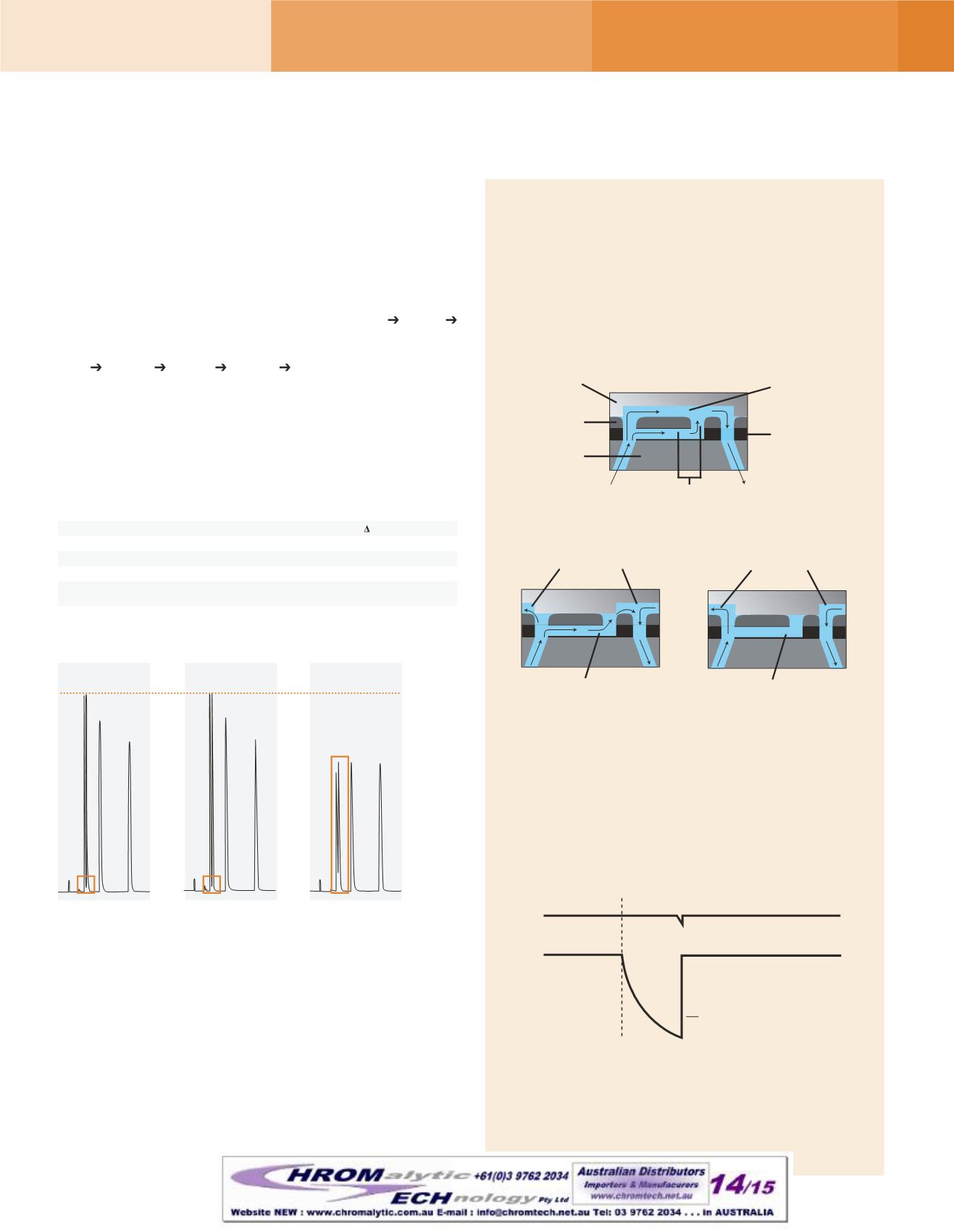

Make-Before-Break isauniquedesign featureof certain

dual-modemanual injection valves.

Flowpathsofmodel 7725(i) and9725(i)withMBBdesign

To maintain a constant, desired high-pressure flow,

Rheodyne’s Make-Before-Break (MBB

®

) design creates

continuous flowbetween the LOAD and INJECTpositions

thatvirtuallyeliminatespressuretransientshocktothesystem.

Apassage in thestator facemakesanewconnectionbefore

oldconnectionsbreak.TheMBBdesign—an improvement

overbypass-style injectors—doesnotdilutethesampleand

iseasy tomaintainand troubleshoot.

MBB valve

Non-MBB valve

Pressure shock

Inject

Pressure

Time

Rotor SealGrooves

MBBPassage

PositionC

Rotor SealGrooves

MBBPassage

PositionB

PositionA

Shaft End

Rotor Seal

Stator

Face

Stator

Rotor SealGroove

Stator FaceSeal

Column

Pump

MBBPassage

A

ColumnOnly

C

Valvew/ 0.020”

Tubing

B

Valvew/ 0.007”

Tubing

ValveOverview