Vespel

®

Ring

Inlet Seals

Leak-tight inlet seals forAgilent GCs!

At-a-Glance

Product

Information

fromRestek

800-356-1688

814-353-1300

InAgilent split/splitless injection ports, it can be difficult tomake and

maintain a good seal with a conventional metal inlet disk. Themetal-

to-metal seal dictates that the analyst apply considerable torque to the

reducing nut, and, based on our testing, this does not ensure a leak-

tight seal.Over the courseof oven temperature cycling,metal seals are

prone to leaks,whichultimately candegrade the capillary column, and

cause other analytical difficulties.

Restek designed theVespel

®

Ring Inlet Seal to greatly improve injec-

tion port performance. TheVespel

®

Ring Inlet Seal ismade from high-

quality stainless steel and features a Vespel

®

ring embedded into its

face (Figure 1). This softVespel

®

ringwill not harm the critical seal on

the bottom of the injector body, and is outside the sample flow path,

for worry-free chromatography.

The Vespel

®

Ring Inlet Seal is designed to seal even after repeated

temperaturecycles andwithout retightening the reducingnut!Todeter-

mine the variances between traditional seals and theVespel

®

Ring Inlet

Seal, we compared the leak rate for each type of seal at increasing

torque (Figure 2), using a high sensitivity leak detector. Notice how

well theVespel

®

Ring Inlet Seal performs at all levels; it seals equally

effectively at torques of 5lb. or 60lb. (Figure 2).Why trust ametal-to-

metal seal when you can get leak-tight seals quickly, easily, andmore

reliablywith aRestekVespel

®

Ring Inlet Seal?

Vespel

®

Ring Inlet Seals are available in stainless steel, gold-plated,

orwith a Silcosteel

®

coating. Use the stainless steel seals for analyses

of unreactive compounds. To reduce breakdown and adsorption of

active compounds, use gold-plated or Silcosteel

®

-treated seals. The

gold surface offers better inertness than standard stainless steel;

Silcosteel

®

treatment provides inertness similar to that of fused silica

capillary columns.

Feature

Benefit

Lower leak rate thanOEM

metal seals.

Low torque, soft seal,

patent pending design.

Exclusive Vespel

®

ring seals first

time, every time.

Leak-tight connections:

no oxygen leaks into your

carrier gas.

Greater sensitivity (less detector

noise) and longer column life

(no phase oxidation).

Reduceswear, prevents damage

at critical seal: no unexpected

downtime.

Features&Benefits

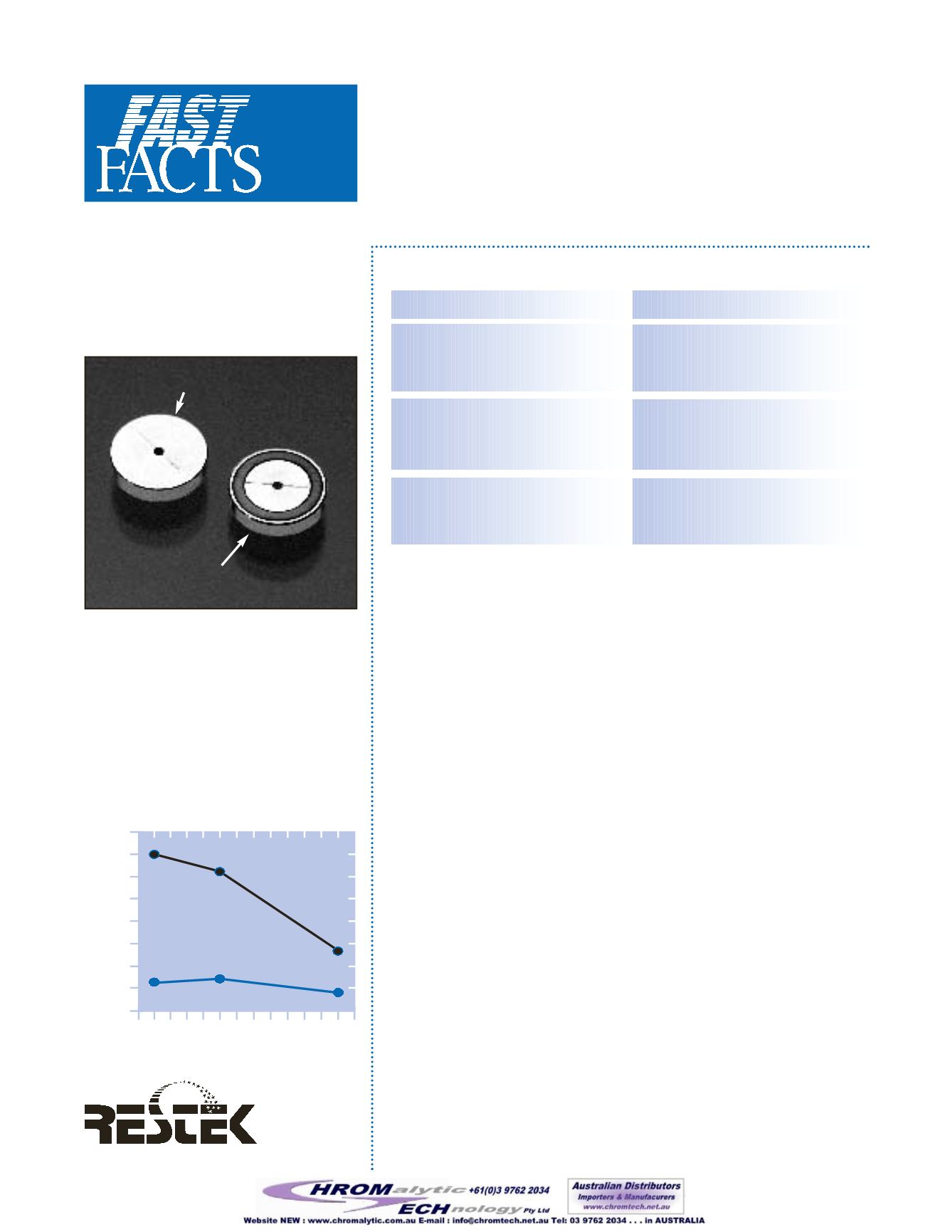

Figure 2.

AVespel

®

Ring Inlet Seal achieves

leak-tight seals even at low torque, reducing the

chance of leaks.

Torque (in. lbs.)

Leak Rate (Log

10

atm cc/sec.)

0 5 10 15 20 25 30 35 40 45 50 55 60 65

0.01

1E-3

1E-4

1E-5

1E-6

1E-7

1E-8

1E-9

1E-10

Vespel

®

Ring Inlet Seal

Traditional Design

Vespel

®

Ring Inlet Seal Design

Vespel

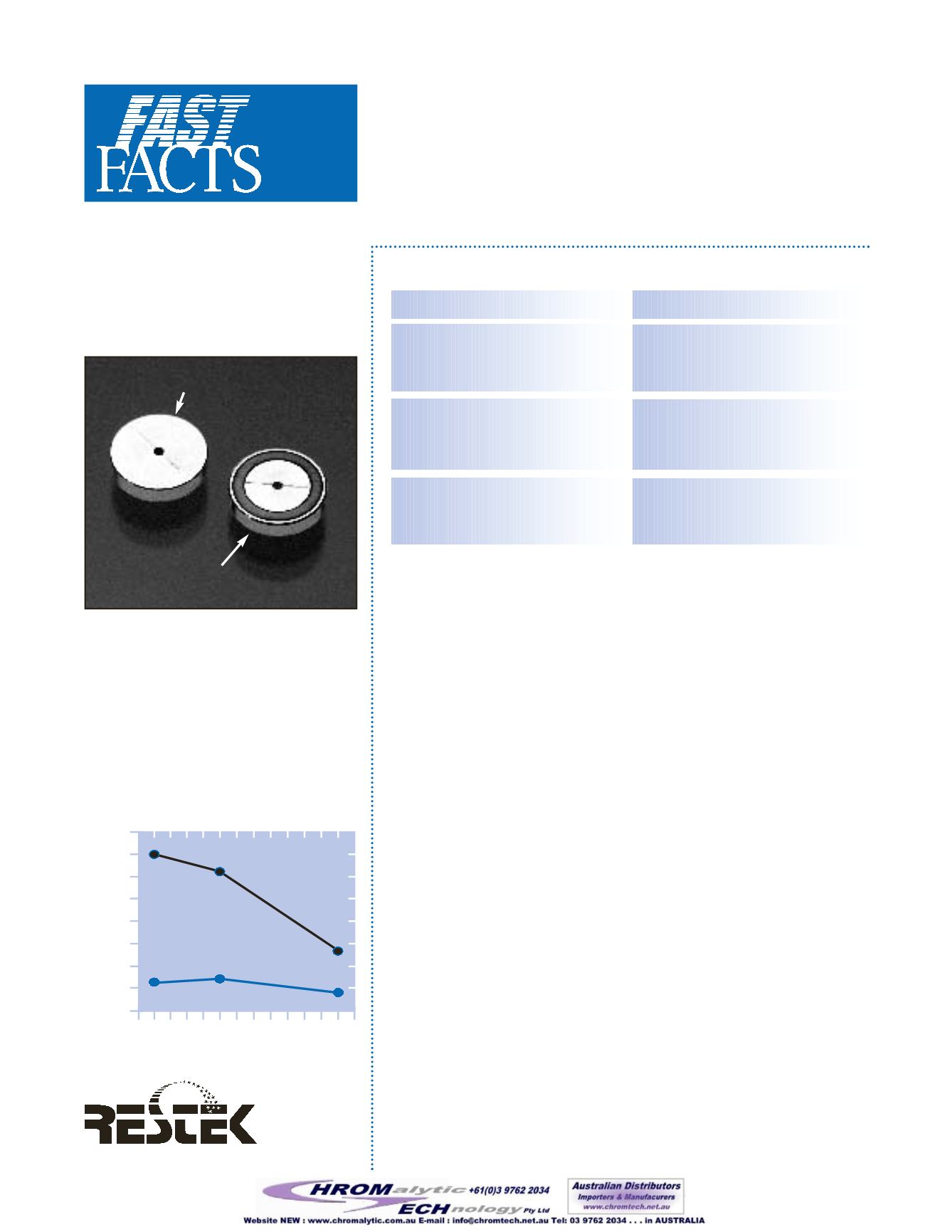

Figure 1.

the

advantage

The soft ring in a Vespel

®

Ring Inlet Seal will not harm the

critical seal or contaminate your sample,

and you’ll get a leak-tight seal every time!

®

Stainless Steel

Original Equipment

Inlet Seal