•

20

•

2007.01

Extend Process Component Lifetime and Enhance Durability

Restek Surface Treatments Improve Sampling and Transfer Component Performance

by Marty Higgins and Carrie Sprout, Restek Performance Coatings Division

• Economical—lower cost than specialty alloys, more durable than traditional stainless steels.

• Versatile—suitable in a variety of environments and temperature ranges.

• Simple—can be applied to existing equipment; stock tubing and fittings also available.

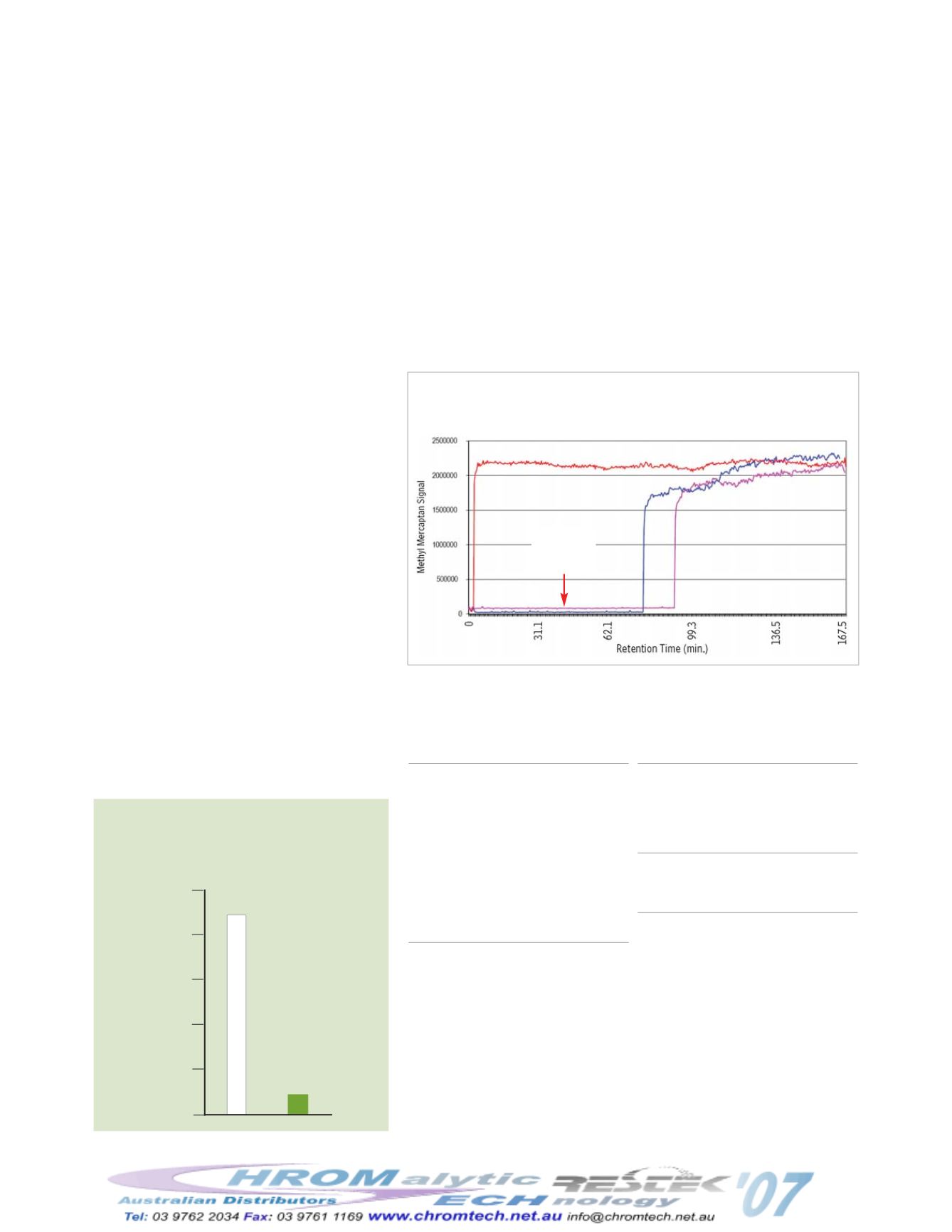

Adsorption problems in sample pathways often

can be traced to the tubing and fittings used to

transfer the sample to the analytical instrument.

Always use deactivated tubing and fittings for

applications involving active compounds. For spe-

cial requirements, ensure maximum inertness and

minimal surface area by applying the deactivating

treatment to electropolished tubing. Figure 1

shows uptake and release curves for 500ppbv of

methyl mercaptan, an active sulfur compound, in

a gas stream passing through a variety of tubing

substrates.

1

Siltek®/Sulfinert® treated tubing

reduces uptake by orders of magnitude, relative to

untreated stainless steel tubing.

In corrosive environments, Silcosteel®-CR treated

tubing is an excellent alternative to expensive

alloys. Silcosteel®-CR treatment extends the life-

time of the tubing, reducing the frequency of pre-

ventive maintenance and helping to ensure the

purity of the process or sample stream.

†

Silcosteel®-CR improves corrosion resistance by

up to 10X over untreated 316 stainless steel (per

ASTM G48 Method B, see graph below).

When surface activity or corrosion are a concern, solutions must be engineered. The Restek Performance Coatings group offers a

family of surface treatments that address activity and corrosion concerns over a wide spectrum of applications. Table 1 lists applica-

tions in which a Restek Performance Coating treatment of sample pathway components prevents adsorption of active compounds,

thereby contributing toward reliable and accurate information, or greatly reduces corrosion.

Figure 1

Sulfinert® treated electropolished seamless stainless

steel tubing (red) does not adsorb methyl mercaptan (500ppbv).

Blue-untreated electropolished tubing; violet-raw tubing.

Sulfur compounds in:*

automotive exhaust

beverage grade CO

2

diesel fuels

environmental samples

ethylene

gasoline

liquefied petroleum gas

natural gas (odorants)

propylene

stack gas emissions

wines and beers

Nitric oxide (NOx) compounds in:*

automotive exhaust

stack gas emissions

Mercury compounds in:*

crude oil

environmental samples

exhaust

stack gas emissions from coal fired electric

power plants

Corrosive environments:**

hydrochloric acid

hydrogen peroxide

seawater

Moisture hold-up in high purity sampling lines**

sample systems

gas delivery systems

process systems

Table I

Applications in which Restek treated sample pathway

components minimize corrosion** or prevent adsorption of active

compounds*.

methyl

mercaptan

adsorbed

*Siltek

®

/Sulfinert

®

treatment.

**Silcosteel

®

-CR treatment.

†

Note that with any corrosive stream, regular inspections are needed to confirm there are no leaks or break-

throughs.

Silcosteel®-CR treated stainless steel

outperforms uncoated metal

by an order of magnitude!

(ASTM G 48, Method B).

0

50

100

150

200

250

Untreated 316 SS

Silcosteel

®

-CR

weight loss in grams per square meter