1-800-356-1688 or

1-814-353-1300

www.restek.com421

SAMPLE HANDLING |

AIR SAMPLING

Canisters

Volume

discounts

?

Call Restek® Customer Service or your local

Restek® representative!

Get the ultimate insurance

plan—order your SilcoCan®

canister with a Siltek®-

treated valve.

*Range of standard gauge is –30" Hg to 60 psi.

Do not exceed canister maximum pressure of 40 psig (2.75 bar).

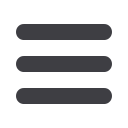

SilcoCan® Air Sampling Canisters with RAVE™ Valve

Ideal for low-level reactive sulfur (5–20 ppb), TO-14A, or TO-15 compounds

• Siltek®-treated canister with optional Siltek®-treated valve offers unsurpassed

inertness, even for sulfur-containing or brominated compounds.

• High-quality, metal-to-metal seal,

2

/

3

-turn valve with stainless steel diaphragms

prevent sample adsorption for more-accurate results.

• Canisters and valves made of 304 and 316 stainless steel to withstand the rigors

of field work.

• Both 2-port and 3-port valves available; 3-port valve includes -30

"

Hg/60 psi

vacuum/pressure gauge (other gauges available).

• Now featuring the proven long life, leak-free performance, and effortless

operation of the new RAVE™ valve. (See

page 420for more information.)

For ultimate inertness, SilcoCan® air sampling canisters feature our unique Siltek®

treatment technology. Even highly active components, at low parts-per-billion con-

centrations, can be readily sampled and stored without loss. The RAVE™ valve is a

high-quality, metal-to-metal seal,

2

/

3

-turn valve with metal diaphragms to prevent

sample adsorption for more-accurate results. Both stainless steel and Siltek®-treated

RAVE™ valves are available, in both the 2-port and 3-port configurations. Each canister

is slightly pressurized with contaminant-free nitrogen prior to shipment.

Whether you are sampling for TO-14A, TO-15, or reactive sulfur compounds,

SilcoCan® canisters are your best choice for inertness. In Tedlar® bags, the stability of

low-level (100 ppbv) sulfur volatile organic compounds (VOCs) is poor, even with-

in 24 hours of sampling. Sulfur compounds react with the metal surface in electro-

polished canisters, so they are unsuitable for collecting and storing low-level sulfur

VOCs. SilcoCan® air sampling canisters, which feature a Siltek®-treated surface, offer

excellent storage stability for sulfur VOCs at very low levels (5–20 ppbv), under dry or

humid conditions. The versatility of the SilcoCan® canister makes it an excellent choice

for collecting and storing TO-14A or TO-15 compounds.

Canisters are the gold standard for ambient

VOC sampling.

Note: If attaching any of Restek’s passive sampling kits to a 3 L canister, use a Siltek®-treated (cat.# 563646) or stainless

steel (cat.# 563647) connector between the two components. Please contact Restek® Customer Service or your local

Restek® representative to order.

1 L Volume

3 L Volume

6 L Volume

15 L Volume

Description

cat.#

price

cat.#

price

cat.#

price

cat.#

price

2-Port RAVE Valve

27400

27404

27408

27412

2-Port Siltek-Treated RAVE Valve 27401

27405

27409

27413

3-Port RAVE Valve with Gauge*

27402

27406

27410

27414

3-Port Siltek-Treated RAVE Valve

with Gauge*

27403

27407

27411

27415

without Valve

22090

22091

22092

22093

NEW!

www.restek.com8

Compound

Day0ppbv

Day30ppbv

Stability (%Change)

%RecoveryDay30

p

-value

Restek

VendorA

Restek

VendorA

Restek

VendorA

Restek

VendorA

Propylene

4.46

4.11

4.33

4.38

3

7

87

88

0.229

Dichlorodifluoromethane (F12)

4.59

4.28

4.12

4.24

10

1

82

85

0.169

Chloromethane

4.34

4.10

4.07

4.12

6

0

81

82

0.237

1,2-Dichlorotetrafluoroethane (F114)

4.43

4.14

4.18

4.29

6

4

84

86

0.172

Vinylchloride

4.32

4.04

4.15

4.36

4

8

83

87

0.136

1,3-Butadiene

4.46

4.11

3.95

4.27

11

4

79

85

0.092

Bromomethane

4.25

4.03

4.10

4.32

4

7

82

86

0.126

Chloroethane

4.23

4.02

4.18

4.33

1

8

84

87

0.159

Ethanol

4.74

2.99

5.95

3.18

25

7

119

64

0.049

Trichlorofluoromethane (R11)

4.38

4.07

4.89

5.02

12

23

98

100

0.240

Acrolein

3.37

3.72

0.10

1.20

97

68

2

24

0.006

Acetone

3.70

3.91

4.85

4.45

31

14

97

89

0.392

Acetonitrile

4.67

4.21

4.08

4.46

13

6

82

89

0.462

Isopropylalcohol

3.32

3.49

3.31

3.91

0

12

66

78

0.381

1,1-Dichloroethene

4.47

4.29

3.84

4.09

14

5

77

82

0.117

1,1,2-Trichlorotrifluoroethane (F113)

4.48

4.24

3.96

4.14

12

2

79

83

0.144

Methylenechloride

4.49

4.48

5.12

5.13

14

15

102

103

0.411

Carbondisulfide

4.53

4.50

4.24

4.86

6

5

85

97

0.115

trans

-1,2-Dichloroethene

4.49

4.29

4.05

4.35

10

1

81

87

0.109

Methyl

tert

-butylether (MTBE)

4.26

4.12

3.82

4.13

10

0

76

83

0.086

1,1-Dichloroethane

4.40

4.07

3.94

4.30

11

5

79

86

0.074

Vinylacetate

4.75

3.69

4.33

4.92

9

33

87

98

0.229

2-Butanone (MEK)

3.89

3.69

4.20

3.89

8

5

84

78

0.848

Hexane

4.38

4.12

3.68

4.25

16

3

74

85

0.930

cis

-1,2-Dichloroethene

4.28

4.12

4.06

4.21

5

2

81

84

0.169

Ethylacetate

4.33

4.17

3.95

4.19

9

0

79

84

0.137

Chloroform

4.25

4.06

4.05

4.20

5

4

81

84

0.164

Tetrahydrofuran

3.92

3.81

3.71

3.95

5

4

74

79

0.132

1,1,1-Trichloroethane

4.34

4.08

3.83

4.04

12

1

77

81

0.127

1,2-Dichloroethane

4.43

4.24

3.69

4.02

17

5

74

80

0.107

Benzene

4.28

3.98

3.85

4.19

10

5

77

84

0.083

Carbon tetrachloride

4.76

4.49

4.35

4.86

9

8

87

97

0.056

Cyclohexane

4.28

4.07

3.92

4.15

9

2

78

83

0.130

Heptane

4.10

3.68

3.85

4.11

6

12

77

82

0.122

Trichloroethylene

4.34

4.10

3.89

4.15

10

1

78

83

0.101

1,2-Dichloropropane

4.49

4.16

3.86

4.20

14

1

77

84

0.074

Methylmethacrylate

4.38

4.33

4.08

4.29

7

1

82

86

0.163

1,4-Dioxane

3.50

3.25

3.74

3.70

7

14

75

74

0.355

Bromodichloromethane

5.08

5.05

3.68

3.93

28

22

74

79

0.325

4-Methyl-2-pentanone (MIBK)

4.47

4.34

3.94

4.07

12

6

79

81

0.237

cis

-1,3-Dichloropropene

4.71

4.31

3.79

4.36

19

1

76

87

0.063

trans

-1,3-Dichloropropene

5.05

4.83

3.92

4.62

22

4

78

92

0.038

Toluene

4.66

4.27

4.30

4.40

8

3

86

88

0.259

1,1,2-Trichloroethane

4.32

4.07

4.01

4.21

7

3

80

84

0.125

2-Hexanone (MBK)

4.48

4.27

4.52

4.49

1

5

90

90

0.404

Dibromochloromethane

7.00

7.70

4.05

3.89

42

50

81

78

0.887

Tetrachloroethene

4.39

3.93

3.84

4.10

12

4

77

82

0.125

1,2-Dibromoethane

4.62

4.37

3.89

4.21

16

4

78

84

0.099

Chlorobenzene

4.45

4.17

4.09

4.34

8

4

82

87

0.147

Ethylbenzene

4.41

4.21

4.22

4.33

4

3

84

87

0.215

m

-Xylene

4.38

4.12

4.21

4.32

4

5

84

86

0.203

p

-Xylene

4.38

4.12

4.21

4.32

4

5

84

86

0.203

Styrene

4.66

4.48

4.40

4.57

6

2

88

91

0.192

o

-Xylene

4.86

4.65

4.38

4.20

10

10

88

84

0.443

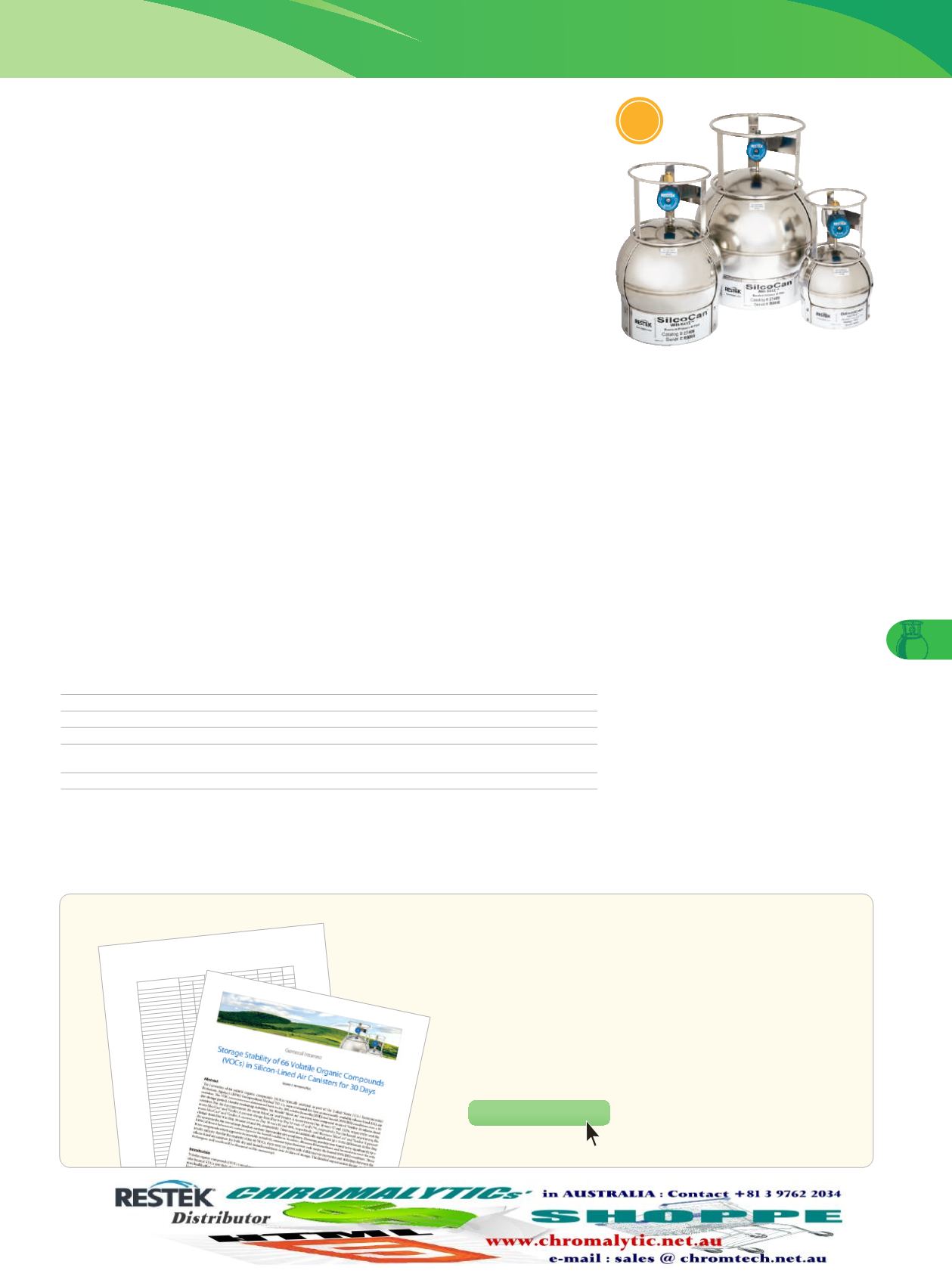

TableVII:

Day0andDay30average concentrationsof66TO-15 components stored in sixRestek® (SilcoCan®)and

sixVendorA canisters spikedat5.00ppbv,30psig,and93%RH.Compounds inboldareanomalies,whichhavebeen

discussed in the text.%Changeequals theabsolutevalueofDay0minusDay30,dividedbyDay0,andmultipliedby

100.p-value fromANOVAofRestek®andVendorADay30 concentrations.

Stable Storage of 66 VOCs

for 30 Days With SilcoCan®

Air Sampling Canisters

Download the free application note by

searching for “EVAN2066-UNV” at

www.restek.com