Basic HTML Version

10-port Gas Sampling Valves & 22-port Stream Selector Valves - SRI Instruments

10 Port Gas Sampling Valves & 22 Port Stream Selector Valves

65-66

|

|

|

|

●

Heated, thermostatted valve oven

●

Standard & custom plumbing configurations

●

Electronically actuated with PeakSimple control or manually actuated

●

1or 2 valve capability

SRI uses 10 port gas sampling valves because they provide more analytical flexibility for the same cost as four or six

port valves. 10 port gas sampling valves can easily be plumbed to replicate the function of the simpler valves, while

offering many other possible configurations, including: Inject Only, Inject and Backflush, Pre-column Backflush to

Vent, Column Sequence Reversal, Alternate Loop Inject, and Dual Loop-Dual Column. Many more plumbing

configurations are possible, especially when multiple valves are plumbed together.

The heated valve oven can be adjusted from ambient to 175°C (up to 300°C for a manual valve). It mounts on the 8610

GC, and can accommodate two electrically actuated and one manually operated valve. Because the valve oven is right

next to the column oven, tubing runs are short with no cold spots, which results in sharper peaks.

Shown above are dual 10-port gas sampling valves in the heated

valve oven of a dual

.

Shown above is a 22-port stream selector valve on our

.

Each valve includes 1/8" stainless steel bulkhead fittings on the front of the valve oven for sample in/out connections.

A single heated (375°C max) fast-cooling adsorbent trap plumbed as the loop of the gas sampling valve is also available

for applications where sample concentration is desired. The trap cools to a user-controlled setpoint, not just to

ambient temperature, so the adsorbent characteristics (water rejection, etc.) can be manipulated.

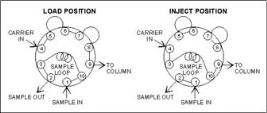

The valve plumbing configuration shown at right is the standard 6-

port configuration. The sample loop is inserted into the carrier gas

stream when the valve is rotated to the INJECT position.

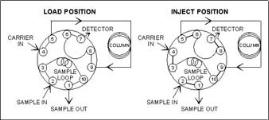

The same 10-port valve can also be configured to backflush the

column when the valve is rotated. Backflushing can often shorten

the analysis by eliminating the need to program the column

temperature up to elute high boiling analytes.