general reference

VICIAG International

|

|

93

premiumgradestainlesstubing

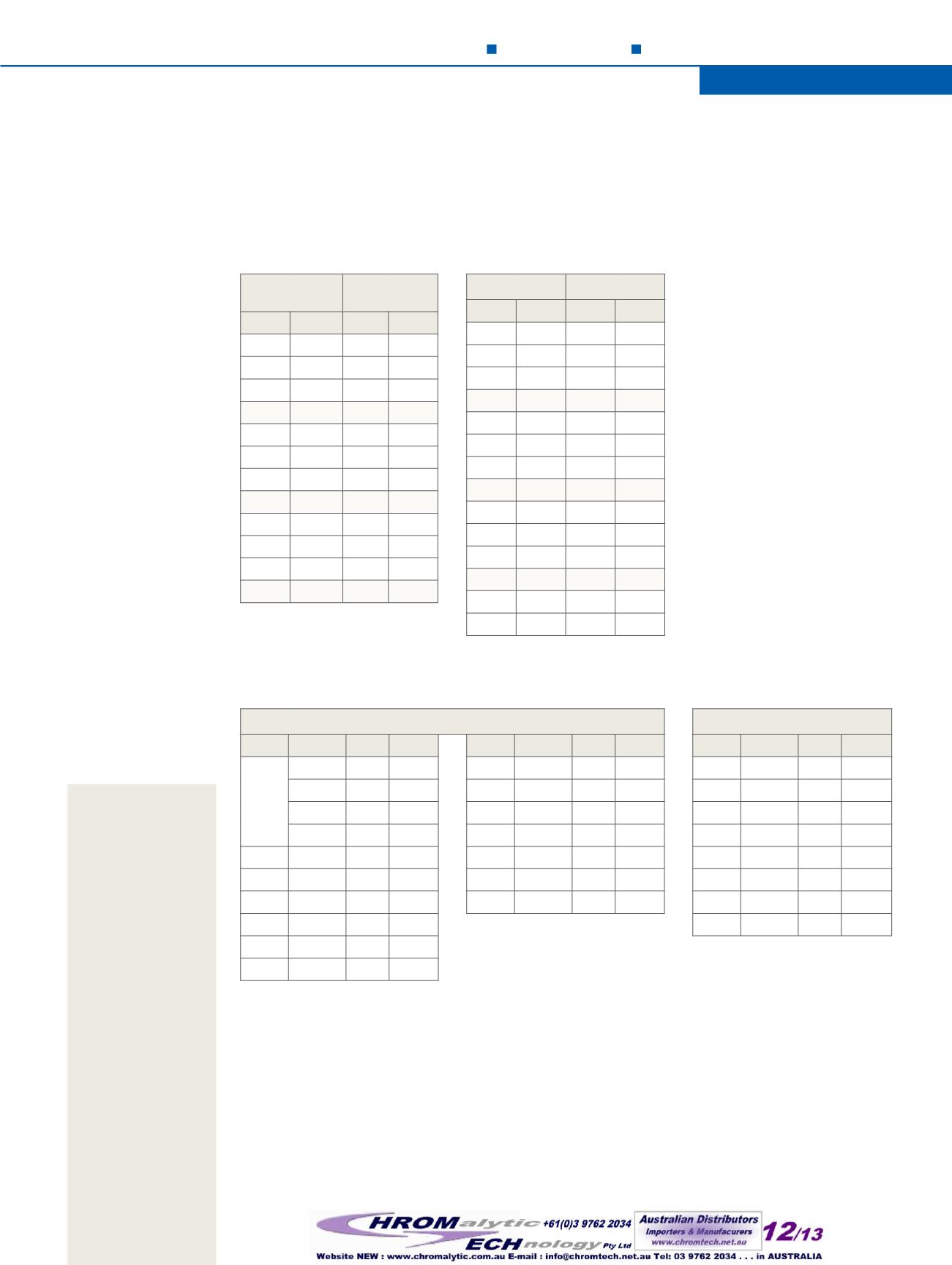

Tubing Volume/length Working pressures – stainless

OD ID

(mm)

bar

psi

1/32"

0.13 1735 25,160

0.18 1601 23,225

0.25 1395 20,230

0.50 734 10,645

1/16"

0.13 1902 27,580

0.18 1835 26,610

0.25 1735 25,160

0.50 1395 20,230

0.75 1067 15,480

1.00 734 10,645

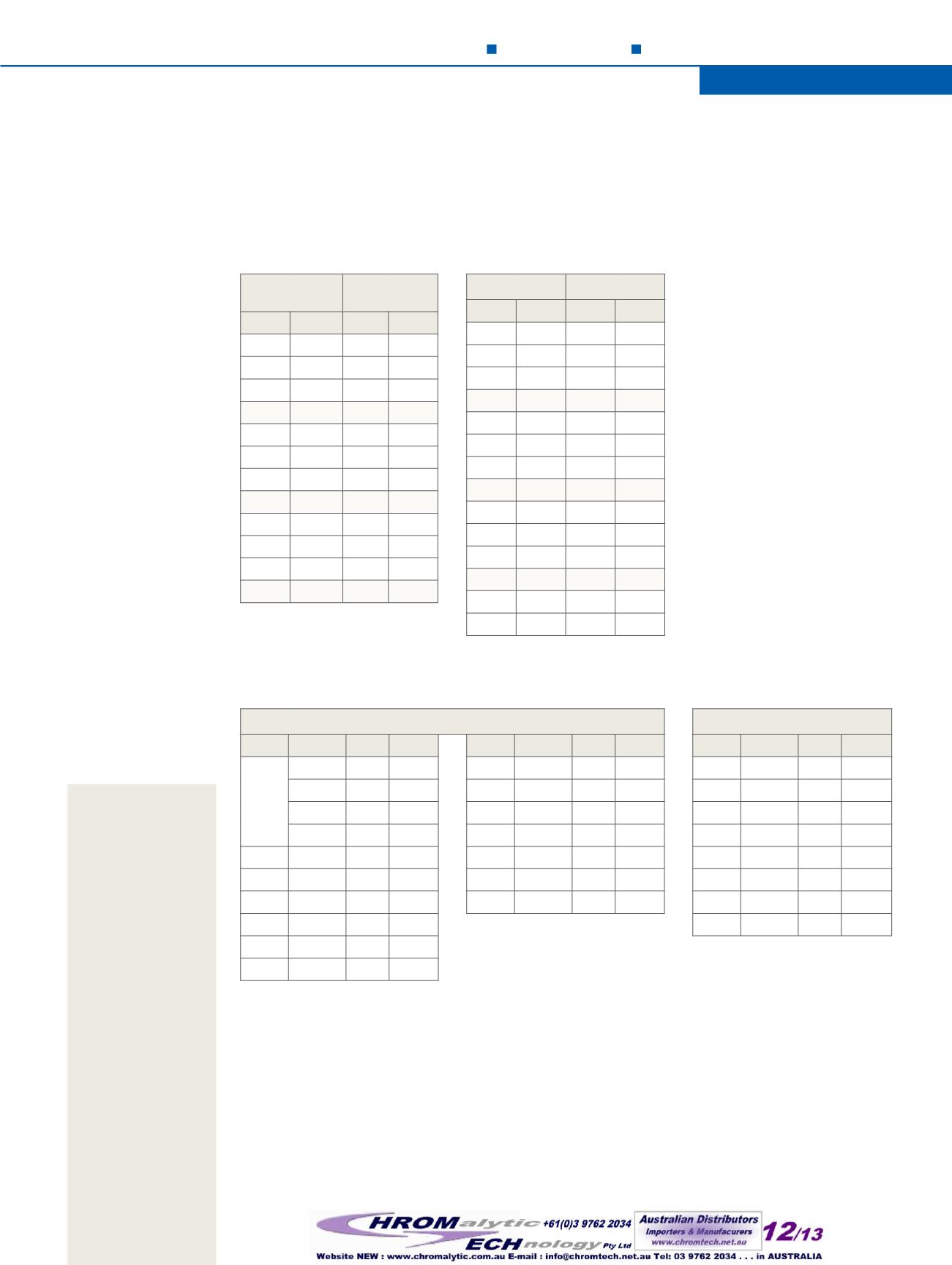

weldedstainlesstubing

OD ID

(mm)

bar

psi

1/16"

0.13 1871 27,140

0.18 1794 26,025

0.25 1717 24,910

0.50 1384 20,080

0.75 1076 15,610

1.00 743 10,780

1/8"

2.10 680 9,860

1/4"

4.65 538 7,800

Maximum recommendedworkingpressures forstainlesssteel tubing

OD ID

(mm)

bar

psi

1/8"

0.68 1622 23,520

0.75 1572 22,800

1.00 1406 20,400

1.50 1075 15,600

1.70 960 13,920

2.16 662 9,600

1/4"

4.65

554 8,040

Tubing ID

Volume/

length

mm inches µl/cm µl/in

0.050 .002"

0.02 0.05

0.064 .0025"

0.03

0.08

0.075 .003"

0.04 0.12

0.10 .004"

0.08

0.21

0.13 .005"

0.13 0.32

0.17 .0067"

0.23

0.58

0.18 .007"

0.25

0.63

0.25 .010"

0.51 1.29

0.38 .015"

1.14 2.90

0.50 .020"

2.03

5.15

0.64 .025"

3.17 8.04

0.75 .030"

4.56

11.58

Tubingvolume/lengthconversionchart

1/16"OD tubing soldbyVICI typicallyhasan ID toleranceof

±0.025mm. This ismuch tighter thannormal commercial grades

of tubing;however, it isenough to result innoticeableerror if

exact volumesarenotmeasured,according to theequation

V=

Π

(½D)

2

L.

Tubing ID Volume/length

mm inches µl/cm µl/in

1.00 .040"

8.11 20.59

1.40 .055"

15.39

38.93

1.52 .060"

18.24

46.33

1.59 .062"

19.86

49.47

1.65 .065"

21.38

54.38

1.70 .067"

22.70

57.78

1.78 .070"

24.83 63.06

2.00

.079"

31.42

80.32

2.10 .083"

34.64 88.66

2.16 .085"

36.61 92.99

2.40 .094"

45.24 113.72

3.18 .125"

79.4 201

3.76 .148"

111 282

4.35 .171"

149 376

working

pressurefor

stainless

steeltubing

Theworkingpressure

for stainless tubing

is calculated from

theburstpressureby

dividingby2.5.

The theoretical burst

pressure(s)were

calculatedusing

Lame's formulaand

a safety factorof 2.

Additionally, these

resultsassume the

tubing isnot subject to

anyother stresses (e.g.

temperauredifferent

fromambient,bends)

thatwould influence

thecalculations. the

endusermustdecide

the safemaximum

workingpressurebased

on this informationand

the specificapplication.