800-356-1688 or 814-353-1300

107

GC COLUMNS |

PLOT COLUMNS

PLOT Column Select ion

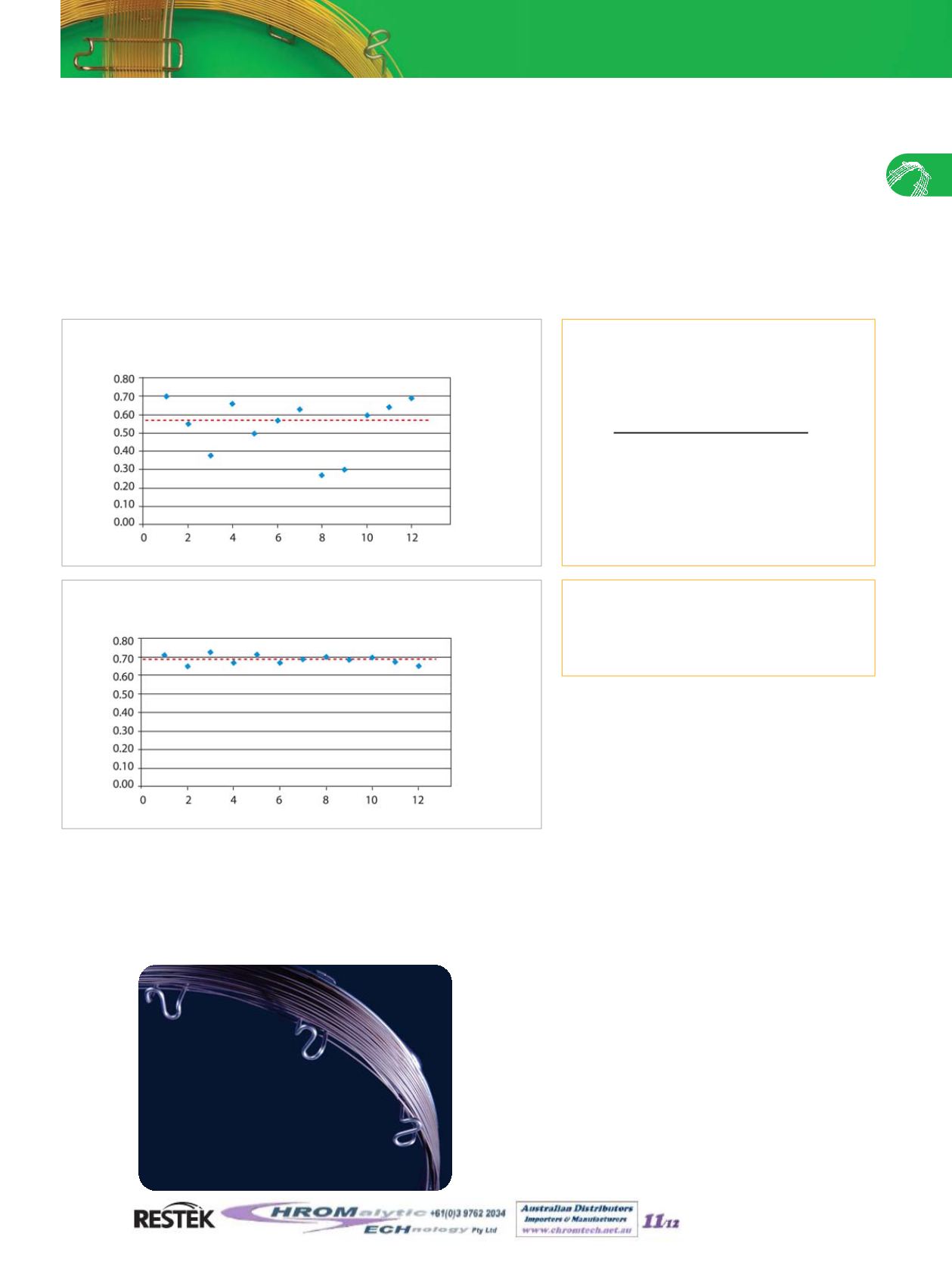

Figure 4

New PLOT columns from Restek offer consistent flow

resistance, giving more reproducible results column-to-column.

In order to evaluate flow restriction reproducibility, Restek is introducing a new factor: the flow restriction factor (F). This factor is

based on the retention time of an unretained marker compound, as measured on both coated and uncoated tubing using the same

backpressure setting (Equation 1). For quality control purposes, methane is used as the marker when evaluating porous polymer

columns and helium is used for testing Rt®-Msieve 5A columns.

Flow restriction factor determination can be used both to assess the degree of column restriction and to evaluate the reproducibility

of the column coating process. Percent flow restriction can also be calculated (Equation 2). Figure 3 shows typical results for PLOT

columns manufactured using a conventional process. Because of the difference in flow restriction, individual columns have very dif-

ferent flow characteristics. In contrast, Figure 4 shows results for columns made using the new PLOT column process (Rt®-QS-

BOND, bonded porous polymer). Clearly, the new manufacturing process results in greater consistency in both column coating

thickness and flow restriction; which, in turn, results in more stable retention times and better performance in Deans switching and

related flow switching techniques.

Equation 1

Flow restriction factor (F) is used to

demonstrate coating consistency.

In summary, Restek’s new PLOT column manufacturing process produces exceptionally robust PLOT columns, featuring concentric

stabilized coating layers. These new columns have more consistent flow resistance and are recommended for applications sensitive to

variation in retention time or flow. These columns are a significant advance in PLOT column technology and are ideal for more effi-

cient, reproducible analyses of permanent gases, solvents, and hydrocarbons.

Equation 2

Percent flow restriction of coated

column.

% restriction = (1 - F) x 100

t

R1

of unretained component

(uncoated tubing)

t

R2

of unretained component

(coated column)

F =

Number of Columns

t

R

= retention time

Note, F values will always be <1 as the coated column

always has more restriction than the uncoated column.

F

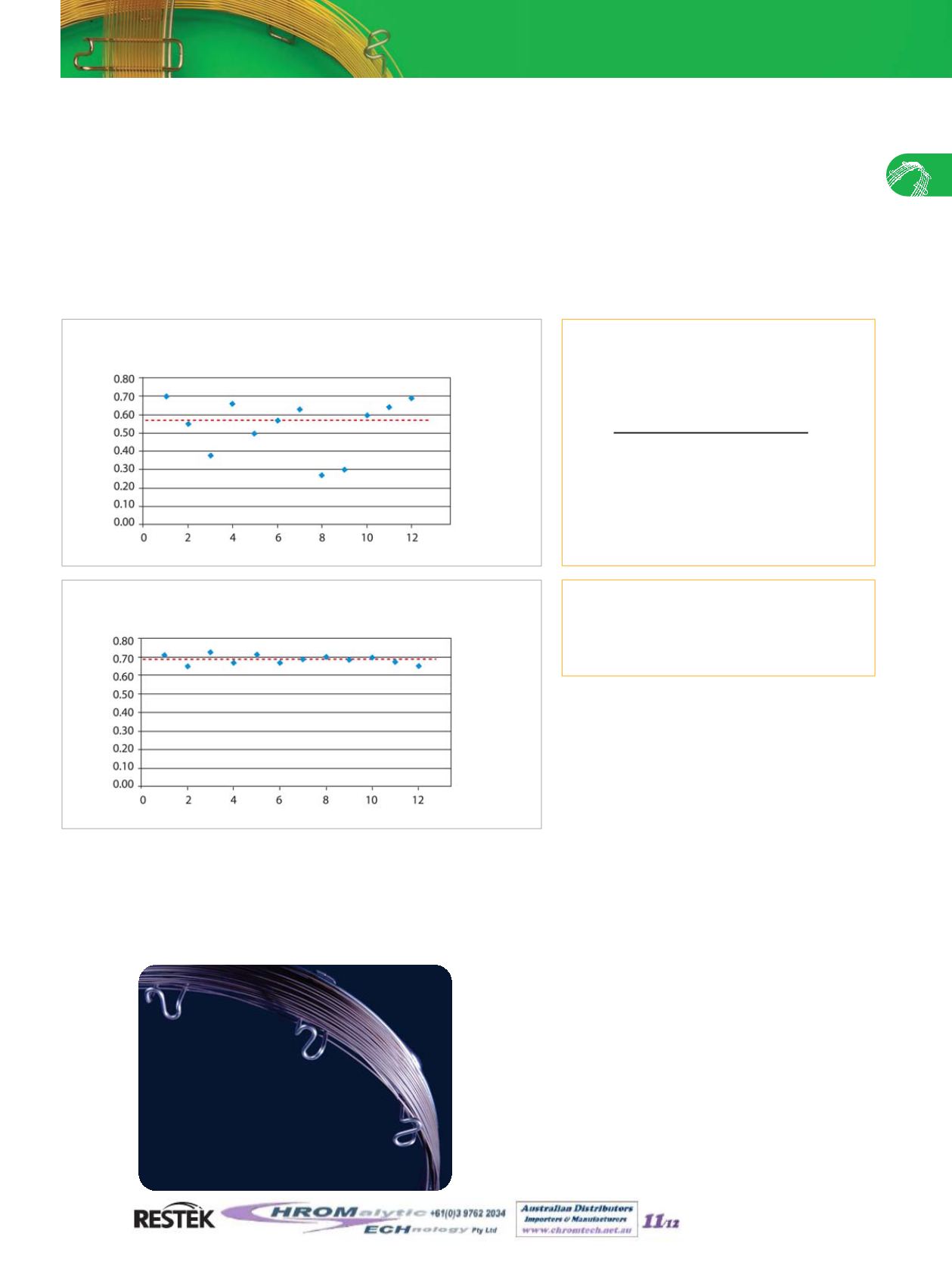

Figure 3

Traditional PLOT columns show significant flow variability,

indicating inconsistent column coating thicknesses.

F

Number of Columns

now

available

!

Metal MXT® PLOT Columns

See pages 108-110.

Website :

E-mail :

TelNo : 03 9762 2034 . . . in AUSTRALIA

Mar 2011