517

OVENS

O

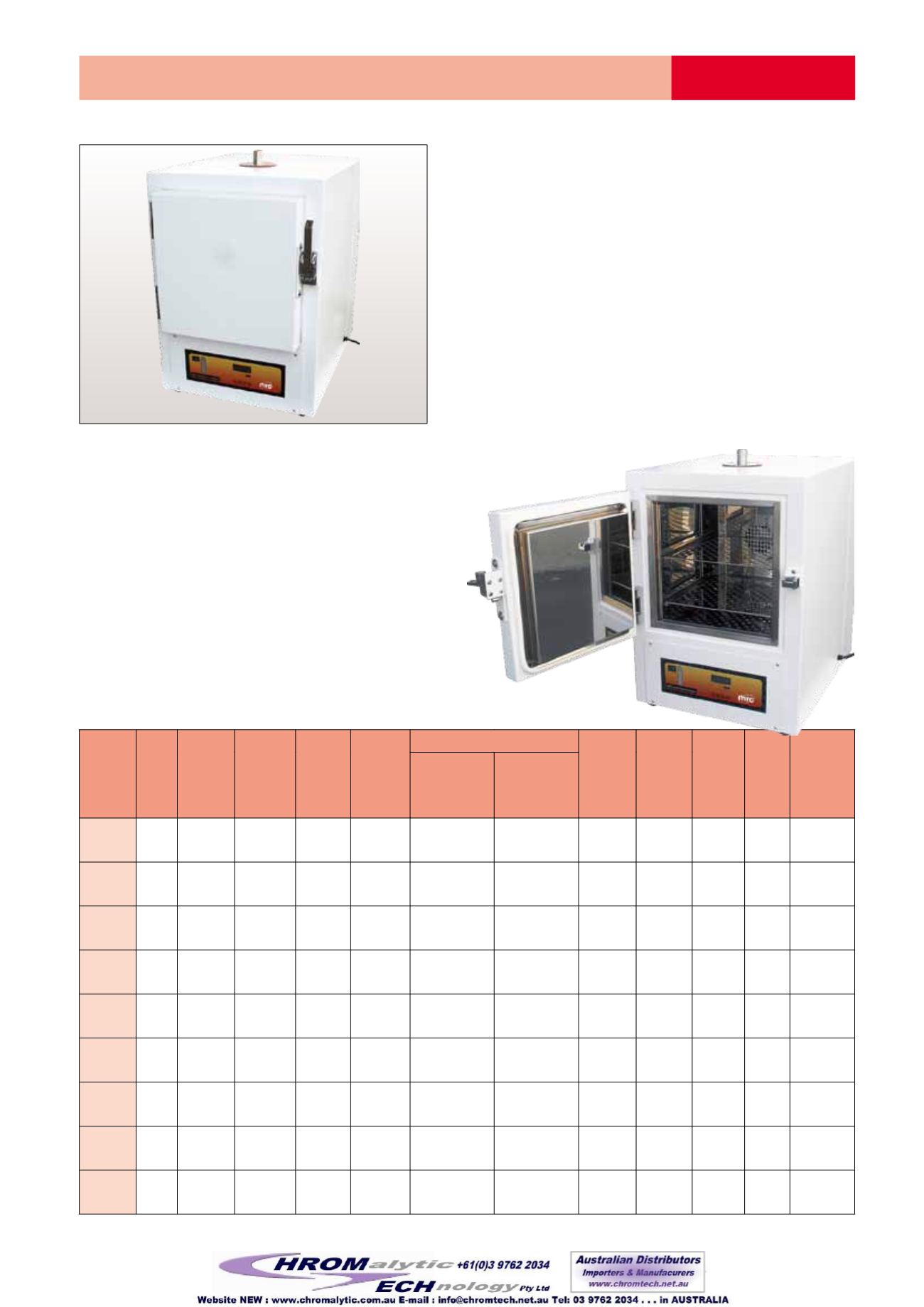

250°C Clean Room

CR-Series, Class 100 Clean Room Ovens

CR/30

All sources of particulate contamination are fully

sealed. The sealed stainless steel interior and gloss

white epoxy finish make the ovens easily cleaned.

Options:

Over-temperature protection to DIN 12-880 class 2

(recommended to protect valuable contents & for

unattended operation)

●

HEPA filtered airflow

available

●

Digital process control timers & multi

segment programmers available

●

Paperless DAQ

(Data Acquisition) graphical recorders available

●

Top access port for independent thermocouple

●

Cable access port

●

Viewing window door

●

Through

door illumination system

●

Stacking frame to enable

units to be stacked one upon another

●

Key-lock

door

●

Door switch to cut off power when the door

is open

●

Fully customized through wall (flange fitted)

designs are available.

Model

Max.

Temp.

(

O

C)

Temp.

Stability

(

O

C)

Temp.

Uniformity

(

O

C)

@250

O

C

Heat-up

time to

Max.

(mins)

Recovery

time to

Max.

(mins)

Dimensions

Shelves

Fitted/

Accepted

Shelf

Loading

Each/

Total

(kg)

Volume

(Liters)

Max.

Power

(W)

Power

Supply

Internal

HxWxD(mm)

External

HxWxD(mm)

CR/30

250 ±0.2 ±3.0

35

4 310x310x310 655x460x670 2/3

10

20

30 1000 230V

single phase

CR/70

250 ±0.2 ±3.0

35

4 310x470x470 655x620x820 2/5

10

30

68 1500 230V

single phase

CR/130

250 ±0.2 ±4.0

35

4 550x470x470 895x620x820 3/9

10

40

121 2000 230V

single phase

CR/180

250 ±0.2 ±5.0

58

5 770x470x470 1115x620x820 3/15

10

50

170 2500 230V

single phase

CR/220

250 ±0.2 ±5.0

75

4 610x610x610 1130x780x850 3/5

15

45

227 3000 single phase

CR/330

250 ±0.2 ±5.0

80

6 915x610x610 1440x780x850 4/8

15

60

340 4500 single phase

or 3 phase

CR/450

250 ±0.3 ±5.0

75

9 1220x610x610 1750x780x850 5/11

15

75

450 6000 3 phase

CR/840

250 ±0.3 ±5.0

-

-

1525x915x610 2050x1065x850 6

15

-

850 12000 3 phase

CR/1790

250 ±0.3 ±5.0

-

-

1220x1220x1220 1750x1420x1450 5

15

-

1810 18000 3 phase

Minimum operating temperature approximately ambient plus 200

O

C. Uniformity values are measured in an empty

chamber, with vents closed after a stabilization period. Shelf loadings are based on evenly distributed weight

Standard features:

●

Designed for operation within Class 100 environments

(US FED STD 209E) .

●

250°C maximum operating temperature .

●

30 to 1790 Liter chamber volumes.

●

Fully sealed low thermal mass insulation to avoid

shedding fibres .

●

Fully enclosed brush less fan motor .

●

PID controller, with single ramp to set-point

facility .

●

Smooth easily cleaned gloss epoxy exterior

●

Polished stainless steel sealed interior enables use of

inert gas atmosphere.

●

Perforated stainless steel shelves .

●

Particle free silicone rubber door seal.

●

Membrane control panel with clear bright LED display.

●

Double skin construction for cool safe outer case

temperature .

●

Fully adjustable chamber

ventilation.