Chapter:

Topic:

INJECTORS ANDGAS VALYES

INJECIlON PORT

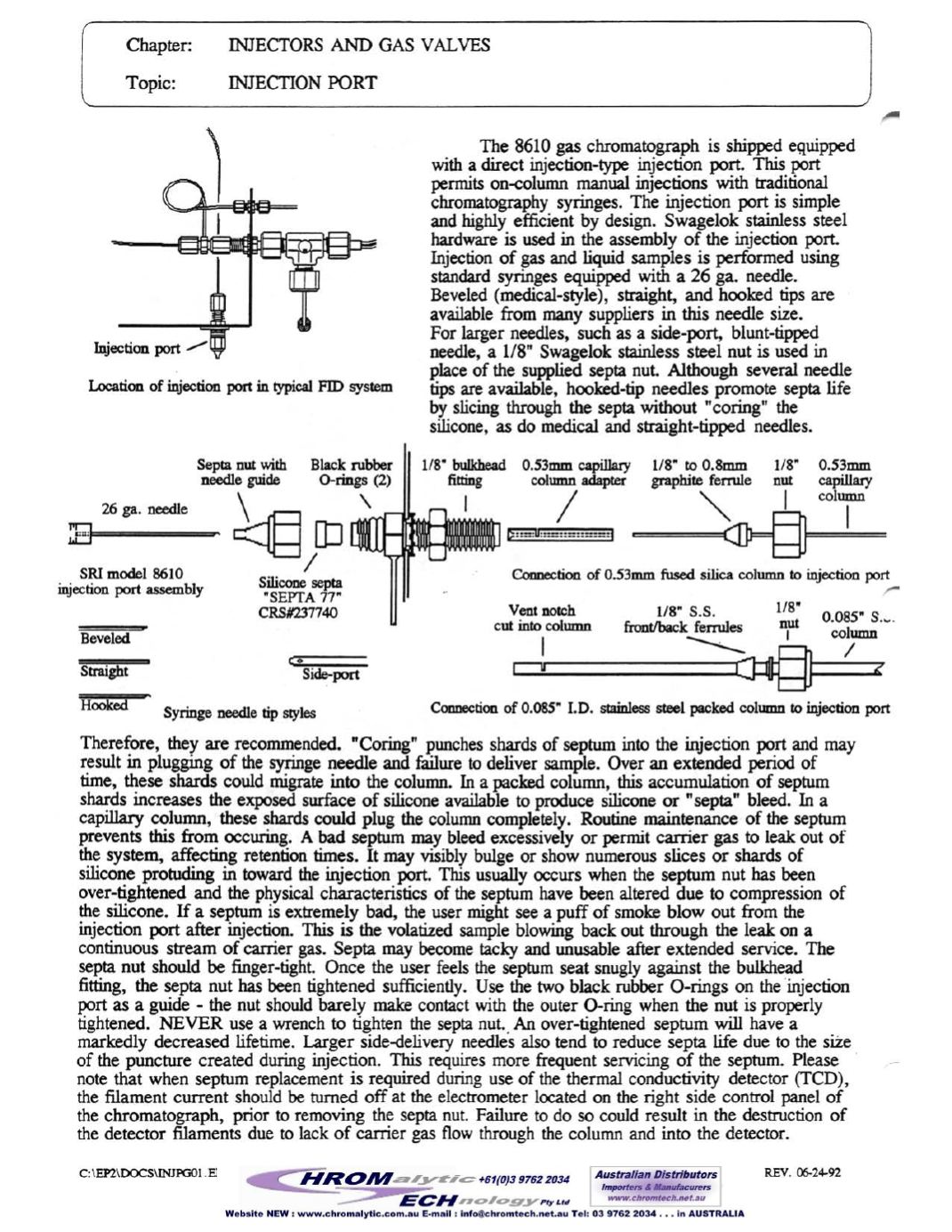

Injection

JX)I1 ,.....

Location of injection

port

in

typical

FlO

system.

The 8610 gas chromatograph is shipped equipped

with a

direct

injection-type injection

port.

This

port

permits

on-column manual injections

with

traditional

chromatography syringes. The injection port is simple

andhighly efficient by design. Swagelok stainless steel

hardware is used

in

the assembly of the injection port.

Injectionof gas and liquid samples is performed using

standard syringes equipped witha 26 gao needle.

Beveled (medical-style), straight, and hooked tips are

available from many suppliers in this needle size.

For largerneedles, suchas a side-port, blunt-tipped

needle, a 1/8" Swagelok stainless steel nut is used in

place of the supplied septanut. Although several needle

tips areavailable, hooked-tip needles promote septa life

by slicing

through

the septa without "coring" the

silicone, as domedical andstraight-tipped needles.

SRImodel 8610

injection

port

assembly

26

gao

needle

:EJ- - -

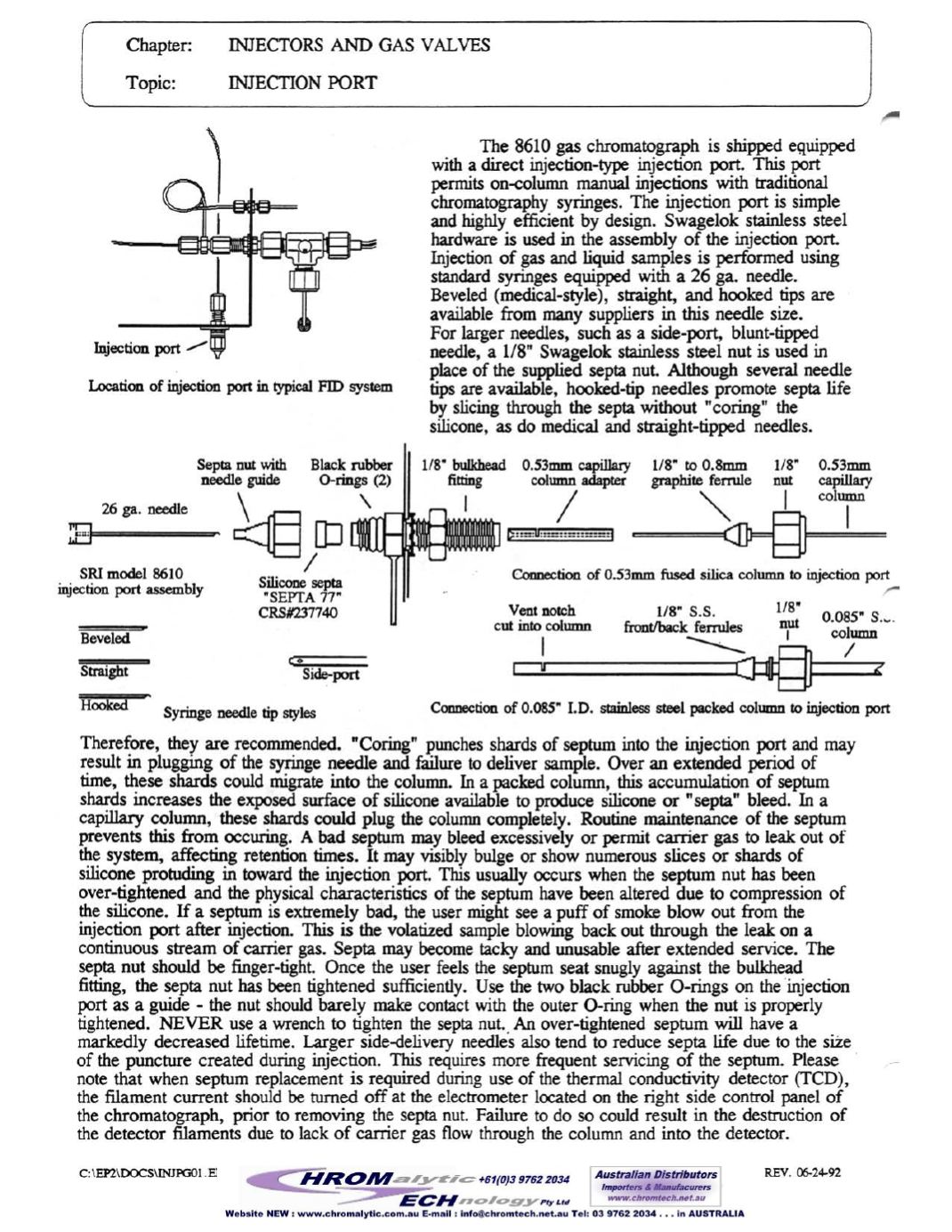

0.53mm.

capillary

column

I

liS-

bulkhead

O.53mmcapillary liS-

to

O.8mm liS-

fitting

column

adaptei

graphite ferrule

nur

I

/

===<~~=

Septa

nUl

with

Black robber

needle

guide

O-rings

(2)

~[lJ

-,

I

Silicooe _

·SEPTA 77–

CRS#237740

Beveled

Stralgbt

Co

Side-port

Hoolred

Syringe

needle

tip

styles

Therefore, they are recommended. "Coring" punches shards of septum intothe injection

port

andmay

result in pluggmg of thesyringe needle and failure todeliver sample. Over an extended period of

time, these shards couldmigrate into thecolumn. Ina packed column,

this

accumulationof septum

shards increases theexposed surface of silicone available toproduce silicone or "septa" bleed. Ina

capillary column, theseshards could plug thecolumn completely. Routine maintenance of theseptum

prevents

this

fromoccuring. Abad

septum

may bleed excessively or permitcarrier

gas

to leakout of

the system, affecting retention times. Itmay visibly bulge orshow numerous slices or shards of

silicone preluding in toward theinjection

port.

Thisusually occurswhen the septumnut hasbeen

over-tightened and thephysical characteristicsof the septum have beenaltereddue tocompression of

the silicone.

If

a

se~tum

is extremely bad, the user

might

see apuff of smoke blowout from the

injection

port

after mjection. This is the volatized sample blowing backout through the leakona

continuous streamofcarrier gas. Septamay become tacky and unusable after extended service. The

septa nut should be finger-tight. Once theuser feels the septum seat snugly against the bulkhead

fitting, the septa nut hasbeen tightened sufficiently. Use the twoblackrubberO-rings on the injection

port as a guide - the nut should barely

make

contact with theouterO-ringwhen the nut is properly

tightened. NEVER useawrench

to

tighten the septa nut.Anover-tightened septum

will

have a

markedly decreased lifetime. Larger side-delivery needles also tend to reduce septa life due

to

the

size

of thepuncture created during injection.

This

requires more frequent servicing of the septum. Please

note that when septum replacement is required during use of the thermal conductivity detector

(TeD) .

the filament current should

be

turned off at the electrometer located on the right side control panel of

the chromatograph. prior to removing the septa nut. Failure todo so could result in the destruction of

the detector filaments due tolack of carriergas flow through the

column

and into thedetector.

C:\EP2\DOCS\lNJPGOI.EPD

REV. Q6..24-92