○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

12

tom of the liner (Figure 2). The benefits of using this type of injection are that

upwards of 3µL to 4µL of sample canbe injected, and injectionport discrimi-

nation is reduced.

A split/splitless injectionport alsomay be adapted for direct injections using

Uniliner

®

liners. In this mode of operation, the split/splitless injection port

split valve (purge valve) must be turned off. Additionally, it is beneficial to

make a leak-free connection (press-tight seal) between the liner and the col-

umn. Refer to the steps presented in the supplied product information sheet,

or found inour catalog, to install aPress-Tight

®

connector. It is alsohelpful to

use graphite ferrules for this connection because the Vespel

®

ferrules may

cause the column connection to fracture if overtightened. Finally, before in-

serting the column into the connector, dip the end of the column into a vial of

methanol for 30 seconds. This causes the polyimide coating on the column to

swell, resulting in a better seal.

A third direct injection technique used for pesticide analysis involves large-

volume injections into a cold injection port. The injected solvents and com-

pounds are cold-trapped on the injectionport linerwalls. The injectionport is

heated to about the boiling point of the solvent, and the solvent is vented out

of the system. The vent is turned off and the injection port is heated rapidly,

allowing the trapped analytes to transfer from the liner to the inlet end of the

analytical column.

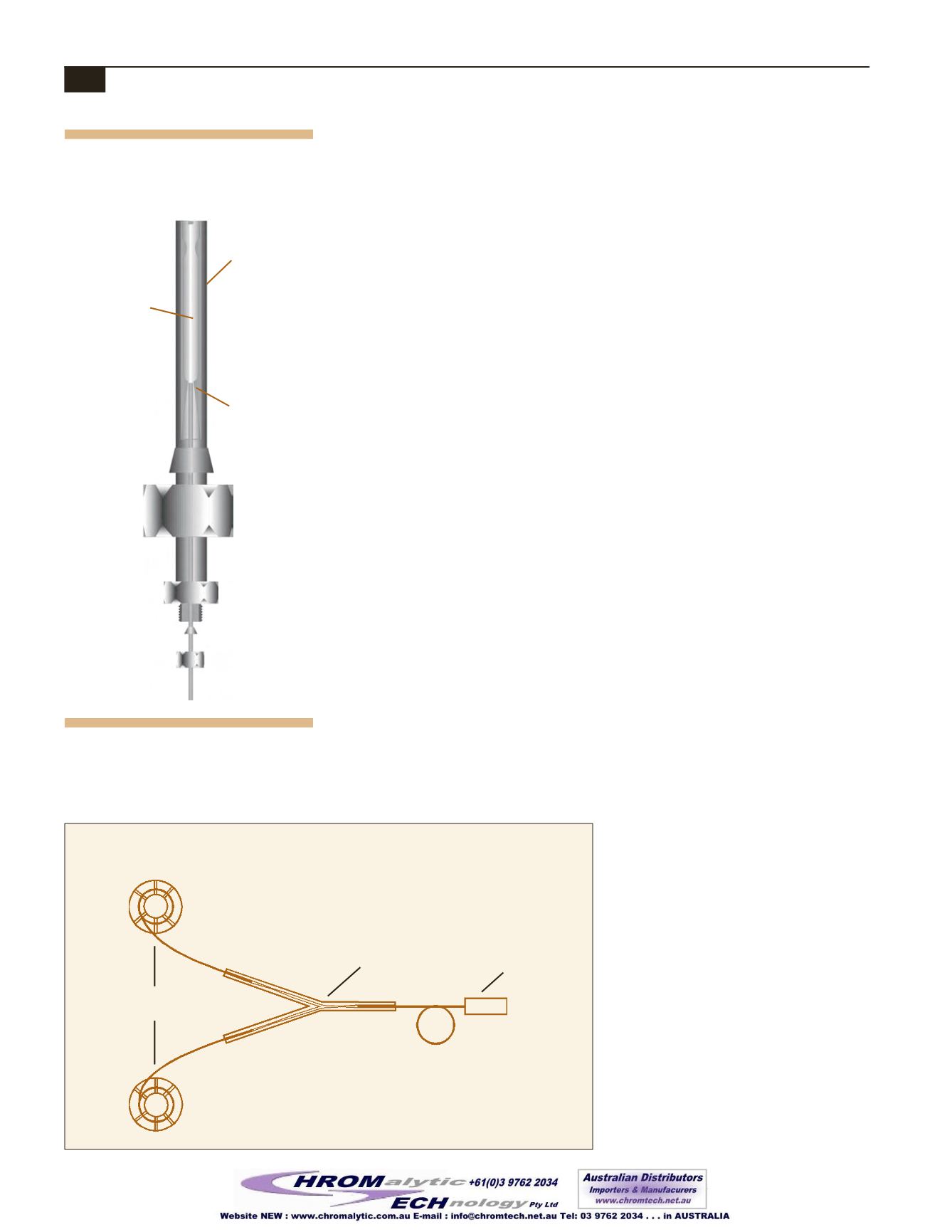

Pesticide methods generally require a second column analysis for confirma-

tion, to give a higher degree of confidence in reported analytes. For dual-

column analyses, we recommend that these injections bemade into a single

injection port and split onto two columns using a glass “Y” fitting (Figure 3).

Although there are alternative ways to set-up a dual-column system, this

method provides the best reproducibility, while achieving the required detec-

tion limits andminimizing instrument maintenance.

Splitless Injections

Splitless injection involves operating a split injection port with the split valve

(purge valve) closed during the injection, allowing all the carrier gas to be

directed into the column. The split valve remains closed for a short time (30

sec. to 2 min.) after the injection in an attempt to transfer as much of the

sample extract as possible from the injection port onto the column. After this

splitless hold, the purge vent is opened, and the remaining solvent and non-

transferred sample are vented out of

the injection port. The purge vent

shouldhavea carbon trapattached to

remove any pesticides and other or-

ganic compounds before being vented

into the laboratory.

Splitless injection requires optimiza-

tion of the purge time to ensure that

the maximum amount of analyte is

transferred to the column, and mini-

mizes the amount of solvent. Gener-

ally, the purge time is determined by

maximizing the area count of the last

eluting analyte. For additional infor-

mation, please contact Restek’s tech-

nical service and ask for the technical

guide

OperatingHints forSplit/Splitless

Injectors

(lit. cat.#59880).

Splitless injection isprone to inertness

problemsbecauseof theresidence time

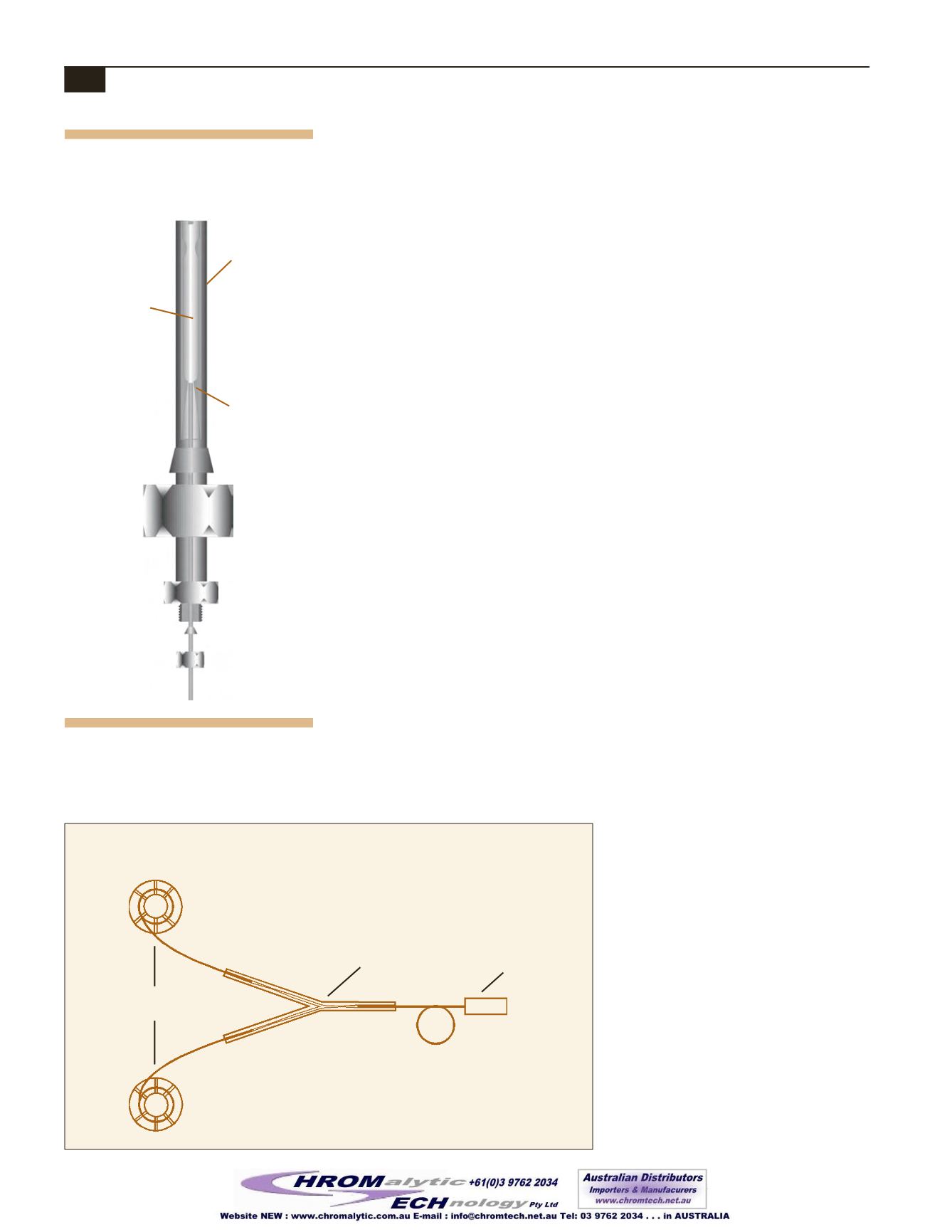

Figure 2: A press-tight seal

connects the liner to

the column.

Figure 3: “Y” fitting provides best dual-column system connection

analytical

columns

Press-Tight

®

“Y” or

Vu-Union

™

“Y” connector

guard

column

split/splitless

or direct

injection inlet

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Press-tight

connection

Uniliner

®

Metal sleeve

adaptor