8

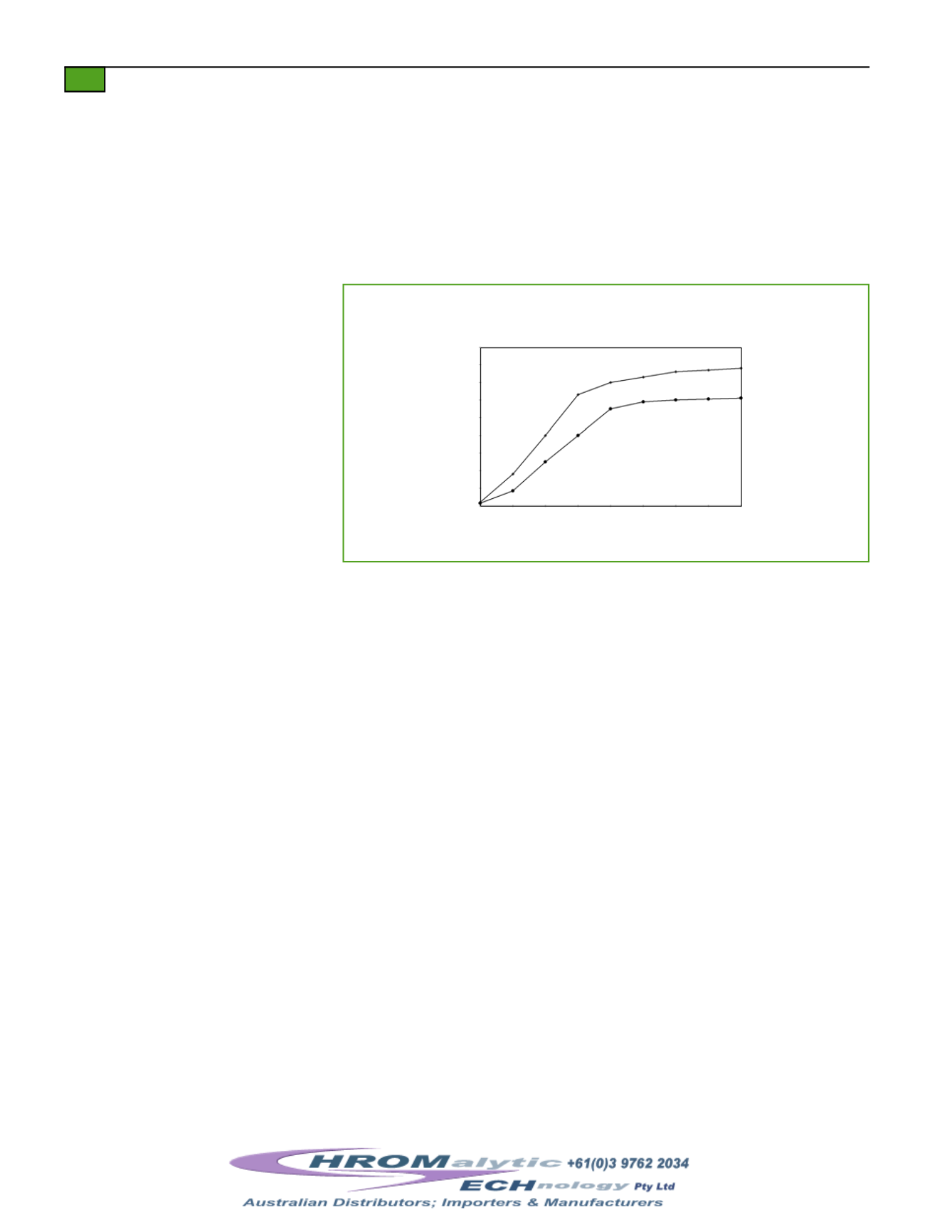

Figure1.

Optimizing splitless hold time.

0 15 30 45

120

75 90 105

60

late-eluting compounds

hold time (sec.)

20

16

12

8

4

0

component area (thousands)

The time period that the solenoidvalve is closed is referred to as the splitless hold-time.

The hold-timemust be optimized toobtain the best performance from the analytical system.

If the solenoidvalve is opened tooquickly, some of the samplewill be lost causing reduced

response. If the solenoidvalve is open too long, the solvent peakwill tail. The splitless hold-

timewill varydependingon column flow rate, injectionport geometry, injectionport

temperature, andvolatilityof the analytes. It is impossible topredict the optimum splitless

hold-timewithout performing some experimentationunder the exact conditions of your

analysis.

Tooptimize the splitless hold time for a particular instrument, prepare a standard that contains

both an early- and a late-eluting compound (e.g., fluorophenol andbenzo(g,h,i)perylene).

Inject this standardover a range of splitless hold times from0.1 to2.0minutes andplot the

data.An example of this optimization is shown inFigure 1.

In this example the optimum splitless hold time is 60 seconds. This is the point on the graph

where the responseof the late-eluting compound levels off.Holding the solenoidvalve closed

longerwill not appreciably increase the response of this compound, butwill greatly increase

the size of the solvent peak. Because the lower boiling compoundwill transfer onto the

column faster, its responsewill level off sooner (in this example~45 seconds).Once this data

has beenplotted, it is possible toobserve the correct splitless hold-time (once again, the point

atwhich the response of the late-eluting compounds levels off). The net effect of this

optimization is tomaximize responseof late-eluting compoundswhileminimizing solvent

tailing.

In addition tooptimizing the splitless hold-time, fused-silicawool shouldbe used in the

injectionport liner to improvevaporizationof highermolecularweight compounds.While

there aredifferent theories regarding theplacement of fused-silicawool, consistency in the

amount of packing and locationof thepacking ismost important. Restek recommends placing

the plugofwool below the point that the syringe needle reaches, but above the inlet of the

column.We also recommendusing agooseneck liner tominimize contact between the

injected sample and the bottomof the injectionport. Thiswill help improve the response of

themore reactive compounds such as 2,4-dinitrophenol, PCP, and thenitroanalines. The

gooseneck liner alsomakes thegreatest improvement in response andminimizationof endrin

breakdown forUSEPAMethod525.

Another technique tominimizemolecularweight discrimination is toperform the splitless

injectionunder ahigher columnheadpressure.Ahigh inlet pressure is advantageous during

injection to control the rapidly expandingvapor cloud in the inlet. Byusing amomentary

pressure pulse for the time that the split vent line is closed, the sample vapor cloud is

controlled and sample backflash into the gas lines entering and exiting the injectionport is

minimized. The effect of the pressure pulse is to increase the amount of analyte transferred to

the column, especially the late-eluting components. This can lead to stationaryphase

overload, however, so itmaybe necessary to increase the capacityof the columnwhenusing

this technique (see the

ColumnSelection

section formore information).

early-eluting compounds

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA